Best Dust Extractor – Head-To-Head

Best Dust Extractor

Construction is a messy business and dust is one of the biggest evils in our industry. Not only can dust be destructive to personal property but is dangerous to our health. Recent OSHA regulations have highlighted how dangerous dust can be and how important it is to capture dust on the jobsite. In our latest Head-to-Head tool testing we evaluated eight of the industries top Dust Collectors in the 8 to 12 gallon capacity size. The lineup includes dust extractors from: Bosch, DEWALT, Fein, Festool, Hilti, Makita, Metabo and Milwaukee. Read on to find out who makes the Best Dust Extractors!

Dust Extractor Lineup

The eight dust extractors used in this Head-to-Head evaluation are listed below. A link to each is included with specific manufacturer specifications.

- Bosch VAC090A 9 Gallon Dust Extractor with Automatic Filter Clean

- DEWALT DWV012 10 Gallon Wet/Dry HEPA/RRP Dust Extractor

- Fein 69908195402, Fein Turbo II X AC 9.3 Gallon Wet/Dry Dust Extractor

- Festool 584014 9.5 Gallon Dust Extractor CT 36 E AC

- Hilti VC 150-10 XE 10 Gallon Universal Wet & Dry Vacuum Cleaner with Automatic Filter Cleaning

- Makita VC4710 12 Gallon Xtract Vac® Wet/Dry Dust Extractor/Vacuum

- Metabo ASR 35 ACP HEPA (US602057800) 9 Gallon All-purpose Vacuum Cleaner

- Milwaukee 8960-20 8 Gallon Dust Extractor

Dust Extractor Testing / Evaluation

For the Dust Extractor Head-to-Head we evaluated the tools in the following categories:

- Air Volume (CFM) Test – Tests the Air Flow volume of the unit in Cubic Feet per Minute. This test was conducted twice, once with a clean set of filters/fleece bag and once with the dirty filters/fleece bag.

- Suction (Water Column) Test – This provides a relative measure of the motors suction power. We also tested suction with a meter to compare the results to the water column test. This test was conducted twice, once with a clean set of filters/fleece bag and once with the dirty filters/fleece bag.

- Airwatts – Calculated standard measurement used in the vacuum industry. Best indicator of the overall relative power and efficiency of the units because it takes into consideration both the water column and the CFM factors. Airwatts was calculated for both the clean and dirty filters/fleece bag.

- Noise – Decibel measurements including the average and maximum value under high load.

- Cost – Current costs available online.

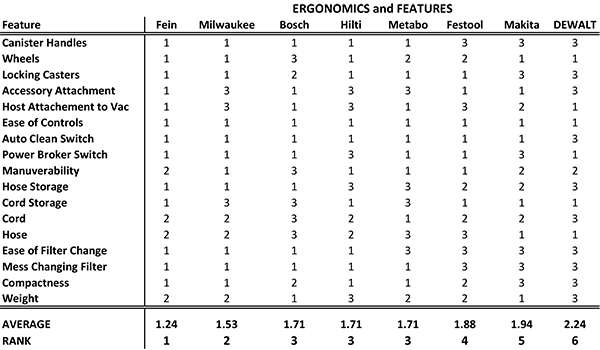

- Ergonomics and Features – We ranked each vacuum in categories including: Canister handles, wheels, locking caster feature, accessory attachment, hose attachment to vac, ease of controls, auto-clean switch, power broker switch, maneuverability, hose storage, cord storage, cord length, hose features, ease of filter change, mess changing filters without fleece bag, compactness, and weight.

All of these tests and evaluations were performed by our Tool Box Buzz Team of contractors. Each of the guys on the team is a contractor, a PRO, a guy that actually uses tools every day to make a living. We know you have lots of places to get this sort of evaluation of tools, but we think ours are the best based on our vast construction experience.

Using Fleece Bags as Primary Filter

For the air volume, suction, and airwatts measurements and calculations, testing was done with clean dust extractors as an “out of the box” baseline. Each dust extractor was equipped with a filter(s) and a fleece bag (without a bag the filters would clog very fast, and we always recommend using fleece bags on the jobsite).

In the second round of testing each dust extractor was used to suck up 20 lbs of drywall compound powder before performing all the measurements and calculations. This helps show the potential performance in a real application. Certainly the results could vary depending on the application, but we felt this was a great way to show before and after performance.

As stated above, we used fleece bags in all of the dust extractors as the primary filter to prevent premature clogging of the pleated filters. Using fleece bags increases the life of the pleated filters (they cost far more than the fleece bags), increases the life of the motor, and makes cleanup easier and safer for users.

Fleece filter bags drastically reduce your EXPOSURE to the vacuum contents – such as silica or lead paint. The use of fleece filter bags is a best-practice methodology, and this was validated by all but one of the vacuum manufacturers that we interviewed for this article. You can learn more about this topic in the following article: using fleece bags in dust extractors.

Dust Extractors – Testing Measurements

One of the key reasons to develop a Head-to-Head test of dust extractors is to objectively measure the relative differences in performance. Tool Box Buzz carefully researched how to best derive these measurements. Our goal was to create a series of measurements that accurately depicted the unit performance.

Our research led us to an industry standard of Airwatt as the objective criteria for overall unit performance, as this unit of measurement is dependent on both pure suction power (measured by inches of water column) and air flow (measured by cubic feet per minute – CFM).

An Airwatt or air watt is a measurement unit of the effectiveness of vacuum devices which relates the relationship between the airflow produced, the suction and the amount of power (watts) a vacuum cleaner produces and uses. The formula we used to compute airwattage was calculated using the ASTM International Standard ASTM F558 – 13. The formula for this ASTM standard is: P = 0.117354 x (F) x (S).

’P’ is the measured and derived power in airwatts,’F’ is the rate of air flow in cubic feet per minute (denoted in cu ft/min or CFM) and ‘S’ is the suction capacity expressed as a pressure in units of inches of water column. The constant in the equation (0.117354) makes the calculated result, over a wide range, come out to where one airwatt is roughly equal to one electrical watt. Our testing methods enabled us to calculate the Airwatt or ‘P’ for each dust collector.

We needed two test jigs built – one to produce inches of water column (S) and one to give us airflow CFM (F).

Air Volume Measurements

CFM Jig

To accurately measure the air volume (flow) through the dust collectors, TBB used a commercial Dwyer hot-wire anemometer. This measuring device has a probe in the air stream that has two openings. In one opening, there is a temperature sensor. In the other opening is a very small wire that is heated up by a power source in the anemometer. As the air flows over the heated wire and cools the wire, additional power is supplied to keep the wire at a constant temperature. The additional power needed is directly correlated to the air flow over the wire. TBB constructed a jig to hold the anemometer probe in the center of the airflow to consistently test units. A close up view of the front of the CFM test rig follows:

TBB took CFM measurements after each unit had run for one and one half minutes. This 90 second run time allowed the anemometer to reach a steady state and allowed the anemometer to calculate and record the average readings for CFM over that timescale. The nearby decibel meter had a stopwatch feature that was consistently used to time the 90-second period for both the CFM and sound level readings. Also, each vacuum was on full power, and if available, had the auto-clean feature turned on.

TBB took CFM measurements after each unit had run for one and one half minutes. This 90 second run time allowed the anemometer to reach a steady state and allowed the anemometer to calculate and record the average readings for CFM over that timescale. The nearby decibel meter had a stopwatch feature that was consistently used to time the 90-second period for both the CFM and sound level readings. Also, each vacuum was on full power, and if available, had the auto-clean feature turned on.

It’s important to note that our CFM measurements will be consistently lower than the manufacturers published data. All but Makita test their CFM at the bare motor inlet. Makita tests theirs at the end of the supplied hose. Our tests were conducted at the opening of the canister with a fleece bag and standard filter attached.. Our testing was done consistently for each unit and provides a more realistic measurement during actual use.

It’s also important to realize that most manufacturers are focusing on CFM as a direct result of the OSHA regulations for silica exposure. Table 1 sets CFM limits for applications like grinding wheels. For a hand held grinder it requires 25 CFM per inch diameter of the grinding wheel. So if you want to use a 6″ grinding wheel, you’ll need a dust extractor that’s capable of producing 150 CFM at a minimum. The tool owner or operator must use the manufactures’ certified data in determining compliance with OSHA for selection of grinding wheel size or any other such determinations. TBB data cannot be used for any compliance determinations.

Suction Measurements

Water Column Jig

To measure static power (suction) we used both an industrial gauge that registered up to 200 inches of water column, and a water column test. The water column test is a much more visual representation of suction so it’s a great way to show the relative suction of the dust collectors. We also used the gauge to calibrate the water column jig that TBB built. The Water Column Jig had a clear 2” PVC water column that visually indicated the suction power of the test units using colored water and a measurement scale. TBB marked the maximum water column reading on to the PVC column with tape that indicated the unit name and test type. The units were tested with the manufacturers’ supplied hoses for each unit and the hose was coupled to the Water Column with airtight rubber compression fittings.

TBB also used the industrial gauge to measure the test units’ suction to create a second set of readings to ensure a good correlation between results of the Water Column and the industrial gauge. Also, each vacuum was on full power, and if available, had the auto-clean feature turned on.

Dust Collector Noise Measurements

For each dust collector we also measured the noise in decibels. During the CFM test, we placed a decibel meter in the same exact location (we placed tape on the floor so the supporting tripod was in the same location) for each vacuum and measured the average and maximum decibel level. Measurements were recorded both when the vacuums were clean, and when they were dirty with drywall compound (under extreme motor performance, the sound levels are higher).

Dust Extractor Head-to-Head Results

Dust Extractor Head-to-Head Results

Measured Air Flow (Volume) Results

Below are the results from our air flow tests. The measured air flow in CFM is shown for both the clean and dirty dust extractors after sucking up 20 lbs of drywall compound. For the clean condition the top three included:

- Hilti 172.2 CFM

- Festool 159.5 CFM

- DEWALT 153.4 CFM

In the second test with a dirty fleece bag and filter, the top three were:

- Makita 134.2 CFM

- Festool 129.7 CFM

- Hilti 111.7 CFM

What’s quite glaring in the results is the drastic drop by DEWALT from third place to last place in eighth.

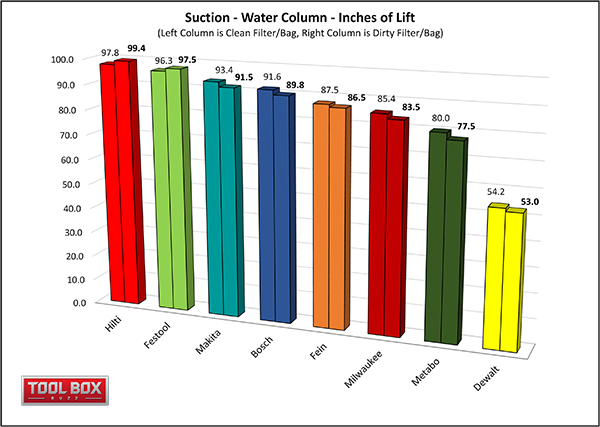

Measured Suction (Water Column) Results

Below are the results of the suction (water column) tests. The measured suction (water column in inches) is shown for both the clean and dirty dust extractors after sucking up 20 lbs of drywall compound. For the baseline clean dust extractors the top three included:

- Hilti 97.8 inches

- Festool 96.3 inches

- Makita 93.4 inches

After sucking up the drywall compound the top three remained the same with:

- Hilti 99.4 inches

- Festool 97.5 inches

- Makita 91.5 inches

Interestingly enough both Hilti and Festool recorded slightly higher suction values in the dirty configuration. Statistically there really isn’t much difference between their first and second test however. DEWALT struggled in this test and was significantly lower than the rest of the field.

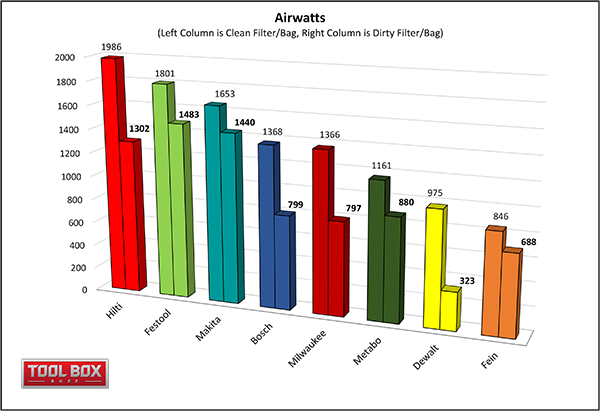

Airwatts – Results

Airwatts – Results

Below are the results of the airwatt calculations. The top three in the clean condition were:

- Hilti 1,986

- Festool 1,801

- Makita 1,653

The results after sucking up 20 lbs of drywall compound were:

- Festool 1,483

- Makita 1,440

- Hilti 1,302

Again we see DEWALT drastically fall off and this is due to it’s struggle in the suction testing above. Both Bosch and Milwaukee dropped about 40% from clean to dirty which is also something to consider when evaluating this data.

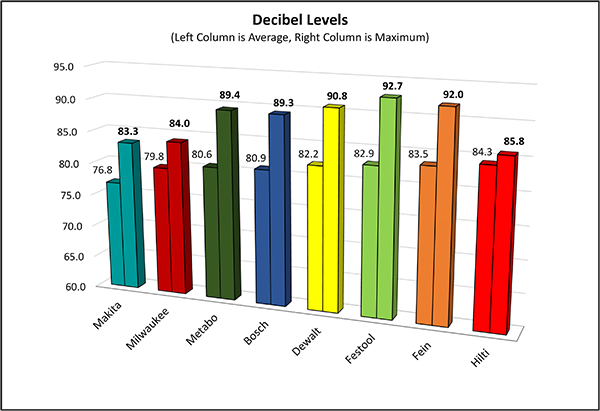

Noise Results

Noise Results

Below are the results from our decibel measurements. We recorded the average sound level along with the maximum values. As you can see below the top three quietest were:

- Makita 76.3 db (83.3 db max)

- Milwaukee 79.8 db (84.0 db max)

- Metabo 80.6 db (89.4 db max)

While the results might look really close, differences in decibel levels are logarithmic, so levels of 90 are actually MUCH higher than levels of 80, essentially 10 times louder. Noise is a serious hazard in construction so any tool that offers lower sound signatures are important for hearing protection.

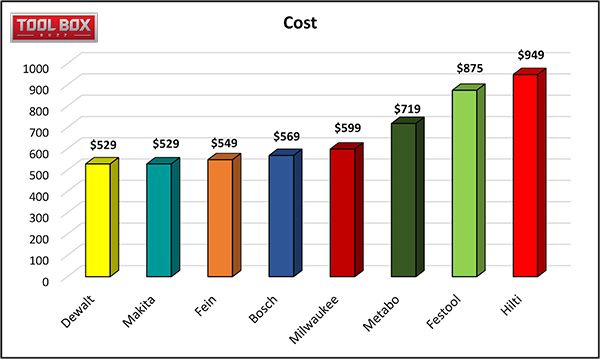

Dust Extractor Costs

Cost is always a factor in determining what tool to buy. Below is a chart showing current pricing (at the time of this publication) for each of the dust extractors that we tested. Both DEWALT and Makita ring in at the lowest cost of $529 which is almost half the cost of the highest priced Hilti at $949. It’s worth pointing out that the total cost may be a bit deceiving, especially with companies like Hilti and Festool that offer robust warranties. Hilti offers a 20 year limited warranty and a 2 year wear and tear warranty and Festool offers full coverage for 3 years, both are significantly longer than any of the other tool manufacturers. While we’re not going to dig into the details of the warranties here, it should be looked at when considering to the total cost of ownership.

Ergonomic / Feature Results

Ergonomics are critically important when considering new tools. For this evaluation we included a long list of features in our ergonomic evaluation. Our team of contractors rated each feature from 1 to 3 for each dust extractor with 1 being the best score and 3 being the lowest score. The average score across each category was used to rank the dust extractors with the top three being:

- Fein with an average score of 1.24

- Milwaukee with an average score of 1.53

- Bosch, Hilti and Metabo tying for third with an average score of 1.71

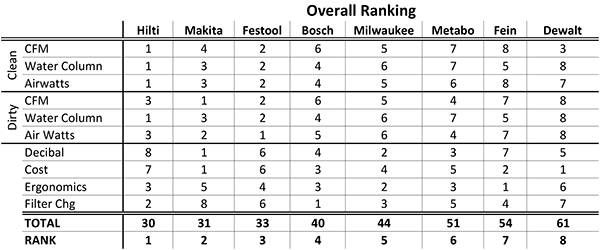

Overall Winner – Best Dust Extractor – HILTI VC 150-10 XE

The toughest part of these Tool Box Buzz Head-to-Head evaluations is coming up with an overall winner. The TBB team has been working hard to develop a good ranking system. The current ranking system assigns a number from 1 being the winner of a category up to the total number of entries. Each category is added up and the tool with the lowest overall score is the winner. Below is a table with all the results from each category. As usual, the top three tools were extremely close and rightfully so as they are excellent dust extractors.

First Place – Hilti

Coming in first place, and what we consider to be the BEST dust extractor on the market today is the Hilti VC 150-10 XE. While it may be the most expensive dust extractor to buy, it offers excellent power and it comes with an excellent warranty that is tough to beat in the industry. The Hilti 20-2-1 warranty is a 20 year limited manufacturers warranty, a 2 year unconditional warranty covers anything including cutting the cord and other non-manufacturer related items, and a 1 day in Hilti’s regional repair shop with pre-paid shipping labels, all of which is really awesome!

Second Place – Makita

Coming in a very close second place was the Makita VC4710. Tied for the least expensive dust extractor we tested, this is an extreme value for contractors on a tight budget. It held its own with Hilti and Festool in the performance testing we did and its also the quietest extractor. There’s no doubt this is a top notch dust extractor with a price that’s tough to ignore.

This extractor was also the quietest one which can be an important safety issue for everyone to consider.

Third Place – Festool

In third place was the Festool 584014. Festool has been a leader in dust control for years so its no surprise to see them at the top of the list. Also priced on the higher side compared to other models we tested, it too offers an exceptional warranty that will keep you working worry free for the first three years. This dust extractor was very consistent in the performance testing boasting the best airwatt measurement in the dirty filter testing.

Final Thoughts – Dust Extractors

Recent OSHA regulations are changing the way we work. OSHA’s respirable crystalline silica rule, which affects 2 million construction workers who drill, cut, crush or grind silica-containing materials such as concrete and stone, as well as general industry operations such as brick manufacturing, foundries and hydraulic fracturing.

We hope this Head-to-Head tool testing we developed clears up some confusion on which Dust Extractor is best suited for your construction applications.

Dust Extractor – Head-2-Head Video

About the author

124 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Can you add a Flex s47 to the tests ?

Milwaukee is very similar

Three points: 1- The clean filter numbers are almost pointless. The machines will be run dirty 90% of the time. Outside of the top three the drop offs are so severe there functionality are compromised.

2- For every 3 decibels noise levels double. So the second place milwaukee is twice as loud as the makita.

3- Biggest disappointment has to be the Fein. They basically created this category and to test so poorly with a new model is unfortunate.

Bonus- The tippy Makita can be a pain in the backside. Add 10/20 lbs of flat weights in the bottom of the canister (using fleece bags) to stabilize it. Not an option if lugging around the job but works if being used at a sanding/cutting station.

We updated the sound section, thanks for the feedback.

Great test! Lots of info here that would require to much time to gather for the average contractor, so greatly appreciated all the work you guys put into this. One mention of the sound section again. Decibels are logarithmic so for every 10db difference it is perceived as twice the volume. 90db is twice as loud as 80db.

Thanks….we updated the sound section.

To be clear – there is a difference between loudness and actual sound energy. Energy doubles every 3 dB – so twice as much damage will occur to your inner ear at 88 as will occur at 85 dB. Loudness has a psychological component – and something has to be 10 dB louder to sound twice as loud – but that is 10 times more damaging not two!

Decibels as a term leaves a lot on the table — it’s incomplete.

Power (xdB/mw, for example) is a 10x discussion, with power doubling every 3 dB (in this case, it’s a relative measurement, not an absolute number).

Voltage measurements (iirc, this is usually what sound is measured at, dBa; xdb/V, or whatever unit of voltage is used) is a 20x discussion, with power doubling every 6 dB (again, that is a relative measurement to a baseline — not an absolute number).

When I started working with RF electronics years ago, it took a long time to wrap my head around the terms used with decibels (a tenth of a Bell — in honor of old Alexander Bell). A simple idea, but not a simple term. It can be used as a unit of measurement, as it can be used both as a measurement of absolutes (with units of reference). Or a relative measurement of magnitude (dB expressed without units implies power/voltage change from an as-is state). The 10x vs 20x issue is largely due to energy formulas vs voltage formulas. Just keep like terms in mind to simplify.

In RF and audio it’s a useful tool because change is rarely noticeable in small increments — our methods of reception are not linear, they are really scale based systems, based on 3 dimensional distribution of energy, and esoteric ideas that are too deep for me.

Thanks Michael – We struggle to find a way to present this data in a meaningful way to readers. It is complicated, but also something readers want to know about. We’ll keep trying to make sense of it in an understandable way.

Incorrect. A 3db is an actual doubling of the sound level intensity (and therefore damage to your hearing.) However, it is only perceived as a small increase by your ear/brain which responds logarithmically to volume changes. A 10db increase is considered a very noticeable volume change by your ears, and in fact, 10x the intensity or power.

These test are very well done. The only thing is you left the best vacuum by far in this market off the test. Do some research on Pulse Bac. thank you. Jon

We will Jon – thanks. We’d love to look at your product, just reach out.

When promoting your product in a comment, you should always write a disclaimer that you work for or have an interest in the company. It this case, you’re the account manager of the company you just claimed to be the best, as stated on your LinkedIn profile.

The only problem with the Pulse is the price! I had to check my pulse when I saw the price, it costs three times more than the Hilti, and the Hilti is not cheap!

I’d like to see the Hilti go up against the $1000 makita

Perceived loudness doubles every 10db. 3db refers to something else (measured power level.)

Pulse Bac is self cleaning. Performance does not drop off like these in the test.

Clean test is not pointless at all. It establishes a benchmark for each machine to compare its ideal performance vs. its in-use performance. If anything it speaks to how well each manufacturer compensated for the inevitable state in which their machine would function.

Fantastic information in an entertaining way! The blog gives so much insight into the subject matter that it does not only become quite easy to understand the concept but to implement it as well.

For me Makita is the clear winner. Festool might be expensive but they also hold value better than any other brands.

Hi guys … Super .. Super impressed with the tests conducted and the detail you went into

My only comment would be that there was no measure of actual input power… I assume you just used the name plate rating on the device

You get full marks

Cheers

Mark – Each extractor was plugged into the same power sources at each test. Is that what you’re referring to?

I believe that Mark is referring to a measure of the actual wattage drawn by the vacuums, such as with a Kill-A-Watt meter, to test whether it differs from the manufacturer’s labeled power draw, as well as to see what difference in power draw there is (if any) when the vacuums are full / under load.

Great info, thanks. An observation.

Under the cost section you briefly mention the warranty, which is good, but no where in the review was the cost of filter bags and HEPA filter discussed and what the average cost per year might be if you could determine a frequency for how often the extractor would need to be emptied.

Jim – We struggled with that, as everyone uses these vacs differently. We did write (and link) to another article on using fleece bags, and how costs come into play. These vacs are pricey, so the cost of ownership is definitely important, it’s just a bit outside the scope of what we cover in these Head-to-Head articles. Thanks for the input though 🙂

I thought this should have been compared as well..Filter Bag and Hepa Filter prices are as important as initial price.

The Hilti with its $200 HEPA Filter have got to be kidding. That probably cost less than $20 to manufacture.

An important cost of ownership factor.

Todd Fratzel, thank you for this post. Its very inspiring.

My compliments on the testing of dust extractors.It was thorough, easy to understand and measured those parameters that are important to us users. I learned a lot.

Thank you

Haim Loran

Thanks for this informative test although it comes too late for the Fein I just purchased. One question related to the pics of the anemometer. The probe tip appears to be oriented differently in the two pics. Did you ensure that it was always oriented as shown in the lower photo? Also, at what distance from the vacuum was the noise level determined?

The probe is in the identical place in both pictures.

The upper picture was taken at a time when the protective sleeve pulled down over the probe elements. We pulled down the protective air-tight sleeve to zero out the meter every time We changed the units to ensure that it calibrated to an absolute zero airflow.

The sound meter was 24 inches away from the units.

My favorite dust extractor is the Dustcontrol DC2900a for power, light weight, easy removal of collected dust, filter life and likely motor life. This is a quiet unit, certainly compared to my other shopvac. The downside is initial price, about twice that of the Hilti. For even more dust storage capacity, and comparable performance in other areas, consider an Ermator dust extractor. The downside to the Ermator is weight, 65 pounds compared to 31 for the Dustcontrol.

when you tested all the dust collectors did you use the same size diameter hose on all of them ?

We used the manufacturers supplied hose on all of them.

[…] which is awesome news for everyone! Also two of our tool reviewing hero’s Pro Tool Reviews and Tool Box Buzz jumped on the case to do their own vacuum comparisons, with some great testing rigs and pointed out […]

I have a thought for the scoring system, you mentioned being open to changing. This is a little complex but would, in my opinion, give really accurate score total.

So I would first go threw the categories being tested & give a 1-100 level of importance to total score, This does add a confusion factor though. Then add up each category turn the test results into percentage based off of closest number easily usable.

For instance:

*Air Volume (CFM) Test (80% out of 100%) 0-200 scale, because max tested is under 200. Divide cfm by 2 to create score(Creating %)…

Example. Hilti-86.1% clean; 55.85% dirty. This is just giving a % of 100.

You could use more complex number if you wanted the best score to be 100% by dividing 100 by the top score, like 100 divided by 172.2=0.58072multiplier)

*Suction (Water Column) Test (80% out of 100%)– 0-100 scale, the number is already in percent.

*Airwatts (90% out of 100%)–0-2000 scale, Divide total by 20 to create percent of 100… Hilti- 99.3% clean; 65.1% dirty.

*Noise (50%)– ?(Could use same scale only backwards)? “Lower is higher”.

*Cost (50%)– ?

*Ergonomics, Features,& Warranty, -etc. (70%)

For totaling: Give each machine a total clean & dirty score

*C.F.M.=SCORE-minus20% (Because you determined it as 80% out of 100 for importance)

*W.C.=” ”

*Airwatts= 100% added

So on & so forth…

Once added all numbers minus there percentage of importance you would have a total number divided by 6 to give you a score in percent form for each machine. Perftect score = 600 (so divide totals by 6)

Hope that makes some kind of sense, let me know If you like the Idea.

Thanks,

Appreciate the input. While this would allow “weighting” categories we approach is a bit differently. When we set out to develop our head-to-head tests, we try to develop tests that are in our opinion fairly evenly matched. The trouble is, what we feel are good tests isn’t what others feel, and at the end of the day, regardless of the system we chose, everyone will rank them differently. The good news is we publish the data, and readers can take that data and make their own rankings. Thanks again.

Typically, when taking anemometer readings with a probe you used in the illustration, the holes in the probe are at 90 degrees to the air stream when reading static psi. This has always been taught in training courses, even by the manufactures. You have yours in line with the stream. I may see this position for cfm, but for static readings it may be incorrect. ?

That picture was just to show the probe, the orientation was turned for the actual readings.

The static pressure in our testing was performed with a water column. We did not use the anemometer for static pressure, only cfm readings.

too bad you did not include Nilfisk

Nilfisk is the original equipment manufacturer for a number of the extractors in this test. They’re included in this test, just not in their own branded units.

The Makita VC4710 is just rebranded Nilfisk-ALTO Attix 50 AS/E Wet & Dry Vacuum 302004234

The Milwaukee 8960-20 is also just a rebranded Nilfisk-ALTO Attix 33

I wouldn’t say rebranded….yes Nilfisk is manufacturing vacs for several brands….but each one is different and offers features that the Brand has requested…..so saying they are rebranded is misleading in our opinion.

Recently revisted this review and noticed a possible flaw in the testing. Not all the vacuums came with hepa filters installed (the festool isn’t even hepa rated). The four lowest rated; Milwaukee, Metabo, fein and Dewalt are. Hepa filters restrict air flow so it would make sense they would suffer on performance. Maybe this helps explain why the Metabo and fein(151cfm) were at the bottom.

That particular festool model is designed for drywall dust, thus the auto clean function and the lack of HEPA. It’s $100 less if you want HEPA with out the auto clean. But that will change the performance results. Also, the makita is $135 more if you get the HEPA filters, $100 for the Bosch, etc. This was an important point when I was picking out my vacuum.

I would have liked to see an orbital sander test done as well. Can the vacuum power be adjusted so that swirl marks are reduced when a DC is connected? Also, which DC’s have an auto tool trigger feature?

It is great that you did all big tool companies, but the best portable small dust vacuum is an American Made one, Pulse-Bac, why was this brand not included? I use Pulse-Bac and would never buy any of the brands you have tested after buying one.

That brand has been out there for 15 years, the originally designed vacuum to handle dust from tools and the only brand that meets all of OSHA Silica rules governing a vacuum used for silica for the past 15 years. Not to mention the original vacuum to automatically back pulse filters clean while working.

Also, maybe testing in real world conditions would be better to know, water lift, CFM and Air watts do not matter if the vacuum clogs while working. How much CFM is lost when being used? how quickly does the vacuum loose lift when filters face, these are the real questions that need answered, as they go right to the performance of the machine. Thanks for the stats, let me know when you actually measure real time performance.

Larry – you have the SAME IP address as Jon Richardson at Pulse Bac??

Wow. Just had a look at Pulse Bac. pricing started at around $1000 and went to $4,125

To clarify we are NOT a testing lab but we feel we do a good job at what we do. Sounds like someone is looking for some air-time and exposure for your vac.

Thanks for commenting – next time be transparent that you work for a manufacturer.Your comment come off “Troll-like” and it’s pretty clear you’re trying to market a product under a false name.

Good catch, Rob. I could never support a company with these kind of unethical deceptive practices.

Agreed – a simple “hey this is Jon from Pulse-Bac” would still carry weight if it was delivered in a nice impartial tone. But now.. well, I think it sours the pallet.

I know its an older thread, but such good info. However catching this guy with the same IP as the other pulse bac comment is a whole different level of awesome and detail, made me laugh. Nice catch.

After revisiting this review I’m questioning how even the playing field was. The higher scoring extractors don’t seem to have a Hepa filter installed (not available on the festool). The milwaukee, fein and Dewalt certainly do and possibly the Metabo/bosch but it is very unclear about the rest (and not possible with the festool). The point is that obviously a Hepa filter would further restrict air flow giving the some brands a unfair advantage.

I would be curious how much the Hepa filter affects performance. The milwaukee can be run with its hepa filter removed because of their multi filter system. This would allow testing with the same unit to discover how much performace is lost.

Interesting comment you shared with us.

In each test case, we used the filters from the manufacturers that the manufacturers promoted as meeting the silica standards.

For the testing the units that are marked “HEPA Ready,” we followed the manufacturers recommendation.

These units, like Bosch, it meant that the paper filters that ship with the units need to be replaced with their Bosch HEPA filters before the dust collector and filter can meet the spec in combination.

In another special case, Festool, their unit has been EPA certified and rated for lead paint removal work for well over a decade. Festool doesn’t seem to have any interest in the concrete/silica market – so, no, they don’t “have” a “HEPA rated” unit, per se. but their dust collector certainly tested well against the other silica-rated units.

TBB based our overall performance measurements on Airwatts. We chose Airwatts because it is a result of both suction and airflow.

On the static suction side, the maximum inches of water column are reached when no air is going through the unit so filters have absolutely no bearing on that particular test.

On the airflow side, all of the units had the manufacturers HEPA or equivalent filters, tested clean, and installed along with clean fleece bags. Our air flow tests were less about the filters because of the fleece bags keeping them clean than if we had run the tests and allowed the dirt to get entrapped into the HEPA filters.

To summarize, TBB remains very comfortable with our approach producing a consistent and level set of results.

Hey been watching your videos here In Australia for a while you guys do a great job.

I just wanted to ask your opinion as I just ordered the Milwaukee extractor featured in this video.

I wanted to know if you guys think it would work well with my Festool track saw,

sander and other wood working tools also?

Many thanks

Jimmy

Absolutely! Good luck.

Is there a good dust extractor for a 14″ diamond blade saw cutting brick, stone or block, I’ve been using a harbor freight dust collector with a dust deputy cyclone and it gets about 99% of dust but it is big and bulky.?

I’d really look close at the Hilti extractors. They do such a great job especially with masonry applications.

The Dustcontrol DC2900C Eco is my choice for this, compact size, 32 pounds empty, can handle months of steady work before a filter change is needed.

The Metabo one is actually made in Germany by Starmix (they did manufacture for other brands like Makita, Fein, Hilti as well in the past).

https://www.starmix.de/en/products/wetdry-vacuum-cleaners/handicraft

Great review! Would like to know how the Dustless HEPA Wet Dry Vacuum stacks up.

Thanks for these tests! I’ll be using angle grinders and drills on my slab and will choose a good dust extractor with the help of your article. I will only use a fleece bag and hepa filter, but I see I have a choice between manual and auto filter cleaning. Haven’t found much online about the two techniques.

Will a cyclone (I already have one) paired with a manual filter cleaner work as well as a machine with an auto filter cleaner? The prices are in the same ball park. Any thoughts will be appreciated.

Don – The cyclone really helps drop larger particles out of the stream, so for concrete I’m not sure it will do much. Auto is my preference as it provides the most optimum performance keeping that filter as clean as possible.

Todd / Rob,

Question about the “dirty” filter tests. Were these done with auto clean on? Also, would cleaning the dirty filter (manually or automatically) yield similar results to the “clean filter” testing, or would a new filter be required to get that level of performance?

Thanks!

The tests were done with the autoclean turned on. Obviously, the older the filter the performance will drop off…but autoclean features have drastically improved that performance for longer periods.

Thanks Todd!

Thanks for the great review.

What about air quality of the exhausted air? How fine are the particles being blown back into the room? To me this is the most important metric.

It’s a great question. Unfortunately we can only test so many things and that isn’t something we are set up to measure.

A couple of comments. First, a good start to evaluation of a complex product.

Airflow – air watts are calculated a given flow point. The two operating conditions you have here are the ends of the “fan” curve. The water column measure is the suction head at zero flow (one condition). The CFM measure is a quasi-open flow condition (#2) with nearly zero suction pressure and maximum flow. Both would have almost zero air watts. What should be done to compare “useful” flow is to use a tube with a sharp edge orifice that has a smaller diameter than the tube. Example – if all these hoses are 2-1/4″ then use a similar sized tube with an orifice plate with a hole about 1-3/4″ in diameter. This will give you a mid-range operation point more indicative of real operation with a partially blocked filter and load from tool pressure drops. With a static pitot tube probe in the tube connected to a manometer, then a comparison could be made just on the relative pressure readings which will show a combined flow and pressure value (higher being better). If you want efficiency, a measure of the input electrical power could be used in conjunction with the airflow. (After pitot calibration in tube with orifice, but that’s more than we can do here.)

Sound – the measure has some merit but has some issues that could be cleaned up in future work. First, the phone mic has limited ability to capture all sound. They are designed to filter out extraneous noise while transmitting speech. Purchase an inexpensive audio mic for sound analysis so that all frequencies are properly captured. Second, consider moving the mic to about a meter away from the source for better representative values. Also, measure sound in several places around the product. Both positional changes may show that directionality may be a factor in the evaluation. Finally, how are you controlling background noise so that they are not intruding on any given test point?

Hope these help.

Thanks! Always love constructive feedback.

Unfortunately I have to agree that this comparison is merely a good start that raises as many questions as it answers. Dusts collection from hand-held power tools is every bit as important as it is from the stationary tools, but actual data is severely lacking by comparison. As noted, the data from this review provides the CFM at effectively no static pressure and static pressure at zero CFM end points, but almost no data about the vacuum curve in between. eg, a vacuum that measured 120 CFM max, but effectively maintained that airflow up until say 45″ of static pressure before linearly dropping to 90″ max static pressure would be far superior in actual usage to one that measured 150 CFM max and dropped down to 100 CFM at 10″ static pressure while still arriving at 90″ max static pressure. (Completely made up example to be clear, just attempting to illustrate the issue.)

Ideal test would adopt methodology as Fan Guy suggests, but with data points for multiple orifice diameters in order to chart the relationship between CFM and static pressure across the potential operating range. (Would be quite useful to conduct a few tests with actual hose + tool connected to determine realistic static pressure of 16′ of 1.5″ diameter hose with an angle grinder, orbital sander, track saw, etc.)

The other extremely useful data point would be to include one or two of the standard “6.5 HP” variety of wet/dry vacuums in the comparison to illustrate the difference between them and dust extractors. I have yet to find an objective comparison point between a standard wet/dry vacuum and dust extractor.

Erik – All good points, but as we pointed out we’re not a testing laboratory, we’re all contractors with full time jobs. We are providing information that’s transparent and can be used by anyone to make their own judgements. Clearly you have a background in this sort of thing so you’re knowledge base is much higher than the average user.

I find many shop vacs noisy enough that I wear hearing protection when using them. Those who are concerned about noise should consider the length of the hose supplied with a vac, or shop for a long hose they can connect. Farther from the vac will be less noisy.

I agree with Fan Guy about testing with a smaller diameter length of pipe at the end of the hose. Again the length and diameter of the hose are relevant, a longer, smaller diameter hose will be likely to reduce flow, but is easier to work with.

Great review. Finally some meaningful, real world data!

Initially I was puzzled by how much your side-by-side results contrasted with to side-by side comparisons of the manufacturers specs from their websites. I dug deeper and downloaded the pdf manuals/spec sheets and discovered that the website listings frequently showed pressure and cfm listings higher than the pdf manuals. The manual specs yielded side-by-side comparisons that were more in line with your results.

I was also puzzled by the erratic falloff in cfm once the bags were dirty.

The vacs all seem to have about the same wattage blower. Perhaps the difference is explained by the surface area of the filters and the size of the bags.

Some manufacturers do show both hose-end and blower-end specs but I didn’t see that breakdown from Makita.

Would you show us where you got the information that the Makita’s specs are made at the hose end?

Lloyd – That came from discussions with their staff.

Dust extractors extract dust… or do they???

Earlier, William Anderson asked about air quality. You answer was that you cannot test everything but I would think this is a fundamental question begged by a dust extractor. This is a major issue of health and safety.

Does it extract dust?

Everything else is honestly only interesting. High mechanical performance numbers are useless if the unit is not properly filtering out the most dangerous particles, which are the ones we cannot see.

It would not be an easy test but no more difficult than the other tests you set up. And far more important.

I applaud your effort, but I honestly think you missed a core test which is of great interest to our lungs.

No offense, but Consumer Reports would have likely done this.

You’re certainly entitled to your opinion. What most folks don’t see if the amount of time that goes into these tests. We interview product managers and engineers from the tool manufacturers. We ask them their thoughts on our testing approach, and try to get their consensus on our approach. Testing the effectiveness of hepa filters for example, that are manufactured by third parties (outside the tool companies) isn’t something we can tackle. But, we can test the performance to suck up materials (one of the primary functions of these tools), and compare them to each other. Yes dust is critical, but the performance to get the job done is as well.

Guys – come on.

The gents at TBB did a great job of doing a relative comparison of several popular units. They developed a test protocol, explained their procedure, conducted the evaluation and from what it appears they presented the results transparently. Yes there was some subjectivity on what and how to test – but that is true of almost any type of testing. Bagging on them about not developing the actual fan performance curves or comparing this and that are being overly critical. It is very easy to Monday morning quarterback someone else’s work. I commend them for being a better job than most reviews that you see on the Internet. Let’s cut them some slack. Or better yet, go out and conduct your own testing (and absorb your costs and time) and post your results of particulate effectiveness or comparative fan performance curve and wire to air efficiencies. Agreed that would be a cherry on top. Can’t wait to see your results.

Jon – Thank you! We put a ton of time into doing these, no one pays us to do the tests. Sure we get traffic and that helps build our brand, but we purposely make everything transparent so guys can make their own final judgement.

Thanks for the support.

Filters are important but they are not what was evaluated. Others have conducted filter tests and they based on industry standards (ASHRAE for example). This was a test of the “vacuum cleaner” effectiveness.

Yes the filter is what removes the dust. So you missed my point.

Great Comparison.

However, not all the extractors came with a .3 micron HEPA filters. So the test is not really comparing apples to apples per say? This will throw off all the test.

Any testing on the Flex vacs coming? Seems to have most competitive pricing.

Nothing planned at this time

I ~believe the Milwaukee is made by Flex.

Great test guys, really appreciate the info and hard work. Would be great to see a common Ridgid or similar vac in the comparison to have a benchmark.

Thanks!

Hi, I was wondering if you considered looking at Dustless Technologies? I am not associated with them at all but they do have a low price HEPA model that meets OSHA regulations. It’s called the Wet/Dry Pro and runs for about $250 USD. However, I can’t seem to find any real world reviews of Dustless Technologies, and don’t want to just trust the companies own youtube videos. Would really appreciate hearing your views on Dustless Technologies. Thanks

Dexter – I’m not familiar with that brand. We’ll keep an eye out for next time we look at dust extractors.

There is a company in Burnaby, BC, Canada that has been selling and renting dust extraction systems for the concrete finishing industry for over 30 years. They manufactured their own fittings for several brands of angle grinders in the 1990’s.

anyway, they currently sell and rent Dustless brand vacuums, along with other brands I am more familiar with. Once the Corona virus shut-down ends here I will take my flow measuring system to their shop and get some readings on new and used Dustless vacs for you.

I would also very much like to know this too. Let’s please look at this option.

I have recently purchased the Makita VC4710 and have several Festool tools. I have had difficulty finding a hose adapter. Are there any that you guys would recommend?

I’ve had some good luck going on the website and calling customer service, I’ve also had good luck using rockler third-party attachments

Just wanted to say thanks for the effort and hours that you did for this review, very informative. Great job. To the neg comments, well you can’t please everyone. My work has the hilti you tested and is, as you concluded, a superior product. I was thinking of buying the Fein turbo II for home. Locally $290 with out the HEPA filter or extra accsesories. I’m second guessing it now after your results. I’m wondering how it would compare with your standard 5.5 or 6.0HP vac you find at the big box stores. I can’t afford to spend more than that really.I know you wouldn’t have exact test results but looking for some advice or opinion on it. Again its for home use. Carpentry, drywaal, small shop and consruction projects. Thanks again

Henry – Good morning. Honestly, for home use, even inexpensive vacs from Craftsman or Ridgid will do the trick. That’s what I use at home most of the time! The big difference on the higher price ones is trying to meet OSHA dust regulations and having vacs that can keep up with heavy commercial use. Even at work we’ve got an old Ridgid we still use for basic clean up around the job.

But only 2 vac has options install on the top boxes with tools,its Festool and Bosch. This is huge benefits. I personally using Bosch for years and like. Only power cord should be little longer.

With the makita discontinued, any idea how the new VC4210L compares?

Hard to say, likely as good or better.

Any new info on this? I’m definitely interested in the new Makita 11 gallon.

Do you have reviews or insight on smaller (sub 5-gallon) extractors?

Also, pricing on these have changed considerably, which might affect your recommendations.

We have not reviewed the smaller ones. Yes, pricing changes all the time, we put the data up so everyone can make their own evaluation, and likely look at pricing when they make the final decision on what to buy.

I purchased the Hilti based on these results, but in thinking more on the subject I realized that the best dust extractor should take into account many factors not listed here in the test, such as:

*tool compatibility* – The Hilti, for example, is meant to fit Hilti tools, which are largely focused on concrete work. To fit it to common woodworking tools like Makita, DeWalt, Festool, etc., you’ll need to get extra hoses or adapters which can really add up, especially with Hilti.

*included accessories* – the Hilti comes with the hose, a basic filter, a single plastic bag, and that’s it. If you want a vacuum attachment, a hose garage, a push handle, adapters, a paper or fleece bag, you’ll need to really cough up some dough. Hilti charges a lot of money for each of these things. 5 fleece bags (only come in a kit): $45.50; HEPA filter: $191; replacement basic universal filter: $121; Vacuum accessory set: $236; push bar: $220; adapter plate with tool box top: $172+$94.25; the list goes on…

Rethinking things as someone that primarily deals with woodworking tools and already owns a mixed set of tools (DeWalt portable table saw and compound miter saw, Festool track saw, various hand tools), it would make sense to factor some of these things into a decision rather than just testing suction capabilities on a few different types of materials from the main hose attachment.

Hi guys, great article … but out of date now as many of these models are no longer for sale.

Any chance of a retest with latest models? Also, would need to ensure all models are compared within the same filtration class (ie. Class L, Class M or Class H). Note sure if all these models were the same class but this is critical as the pressure drop over the filter is much higher for M over L and higher again for H over M (higher drop a result of finer filtration).

Cheers, Simon

Simon – Not anytime soon, lots of other tests on the horizon…we typically won’t redo for several years or longer as we have so many other requests.

Thanks for the reply Todd.

I had been tossing up the latest Makita (VC4210M) and DeWalt (DWV902M-XE) M Class extractors. After reading your review, leaning towards the Makita!

The latest DeWalt seems to have addressed some of the issues in your test as the new model has two filters and automatically switches between use/cleaning every 30 seconds. It’s also got flow rate monitoring and alarms if low. Hence, the drop off from before/after the bag of drywall should (in theory) be much less. However, as flow rate and static pressure still seem to lag the Makita (from their published data) and the latest Makita also has auto filter cleaning and flow rate alarms etc. So … DeWalt may have closed the gap a bit – but I’m thinking the Makita is a safer bet.

However, if any of your guys (or indeed readers) have any experience with the later models Vs the earlier DeWalt/Makiita – I’d be interested in any insights.

Thanks again, Simon

The Makita would be an excellent choice. It’s made by Nilfisk in Europe. They are the leading commercial/industrial vac manufacturer possibly in the world. The VC4210 is actually the Nilfisk Attix 33 in Makita colors with Makita specified attachments. It is sold under various labels (Milwaukee, Mirka, Flex and Nilfisk also). The bags and filters for each sub-brand are interchangeable, so shop around. Hose parts may not be as each company specifies their own preferences.

It appears, as others have commented, that the Milwaukee dust extractor that was tested in this article is also a Nilfisk Attix 33. So I am guessing that the Makita VC4210 which is the same Nilfisk model would perform very similarly to the Milwaukee above, which is to say, not as good a performance as the old Makita.

Something to note, though, about the old Makita tested in this article is that it was tested without a HEPA filter installed (as mentioned below by Todd). I wonder how much of its impressive performance is due to not being bogged down by the filter?

Mark – It’s true there are only a few manufacturers making most of these vacs and re-labeling them. However, while I can’t be 100% certain, I think most are tweaked a bit based on specific manufacturer’s requests. You bring up a great point on the filter, we tried to chase that down and we couldn’t confirm or deny which filter was used that day.

So I was looking at buying the Makita tool you listed but seems like it has been discontinued… It has been replaced with a new model (VC4210L). Any chance that you run your tests with this model and update your results? I looked in Amazon and the new model does not have great reviews (for what its worth), so I am curious how much alike is with the older model.

Daniel – Not likely to happen anytime soon. These tests are a TON of work, and we have a long list of other tools to do Head-to-Head comparisons on. The new one is certainly a solid unit.

[…] to get a better picture of their complete system of tools. This vacuum was featured in our previous Dust Extractor Head-2-Head comparison and will be the subject of a stand-alone review soon. When connected to the ASR 35, the […]

Why was a $1500 hilti vacuum used but not the Bosch GAS20-17AH for the same price that delivers 300 CFM?

I feel like this is a sponsor paid “test”.

Chandler – When we do these tests we contact every manufacturer and tell them what basic parameters we’re looking at and ask them to supply a tool that best fits the category that they feel they compete well with. Every manufacturer supplies a tool, and they ultimately decide if they want to participate. We’ve never been sponsored for a head-to-head and quite honestly I take great offense at the suggestion.

The Hilti and the Bosch are both made by Kärcher.

Hilti can charge more because of their superior customer service. Most of these dust extractors are made by two or three specialist companies that most people have never heard of. There isn’t a bad extractor amongst them. Some may fit your needs or budget better than others.

It used to be that who made a product had a lot to do with its quality, but that is much less the case these days. Super cheap products and high-end products all get made in the same facilities and to different specs. Even the same brands have an entry level, mid level, and high-end line, and comparing them because they all have the same brand logo on them would be a mistake. In previous generations, you could say, “I buy [brand] because they make great products.” It would be reliable because all their products were made in 1 facility and to very similar standards. That would now be an oversimplified view of how products are made. You can only really compare the performance of specific models from specific brands, with some general brand reliability and warranty factored in. Just because two products are manufactured by one company, tells little of the story.

I was wondering if their 40/1 Tact TE Hepa performed well they have the same size hepa filters for cheaper for the Hilti gen 1 VC 150-10 XE that was tested on here

Some feedback on what I bought … got the Makita VC4210 and using it with bags. It’s a good unit, but my regret is not buying a larger unit. When using it to extra saw and router waste it just fills up too quickly (may be rated 10L but the bag is hard pressed against the filters with less than half that volume.

So maybe worth adding a “real” or “usable” bag/drum capacity to any future head to head?

Cheers – and thanks again for the original test info.

Hi,

I searched an could not find any confirmation that the Makita was reviewed with the optional HEPA filter installed. I ask because the the impressive low noise would be especially impressive if the filtration was like to like with the other extractors.

I understand that this Makita is discontinued, but I am wondering if an expectation that an extractor can run this quietly can be contextual to a true HEPA filtration system.

Thank you

Dusty – If memory serves me correctly, every vac was tested “as shipped” which would mean we did not use the optional HEPA. But it’s been quite awhile since we did this so I don’t truly remember.

I use a belt sander and a flex drum sander for a lot of Intarsia work. The dust collector I had seemed to create more dust than it collected. What would you recommend for this use?? Something that can suck the dust as I sand. I start with 80 grit sleeves and move up to 120, 180 and 220.

Again, thank you for the data. I reconfigured it per your suggestion, and I determined Airwatts and cost didn’t matter to me. I don’t work enough for the former to matter much and, although cost matters, I wanted to know how they ranked assuming I could buy any of them (untrue, but I was curious nonetheless).

If I remove the rankings for Airwatts, Makita ties Hilti. The rest maintain their rankings.

If I remove the rankings for Airwatts AND cost (my preference), Hilti is 1st, Festool is 2nd, and Makita is 3rd. The rest maintain their rankings.

You also have to consider that you don’t always want the most powerful vacuum. I’m not sure about the Festool tested here with AutoClean (which probably wasn’t the best dust extractor in their product line to test here as itk’s designed for drywall & concrete), but the other Festool dust extractors can adjust the airflow to avoid swirl marks when sanding.

The BEST information available! Thank you so much. This helped me decide to purchase a Hilti dust extractor.

I recommend updating your links to purchase the tools so that you can receive some affiliate money. You already did all the hard work – might as well get a little return for your efforts.

Fleece bags are for small quantities of dust (and wood chips) not for drywall work. It’s in the manual. Using fleece bags on drywall defeats the purpose of AUTO CLEAN systems. Think about it- vac is built to shake the dust off of filters and continue working all day- with clogged fleece bag it cannot clean itself. If you think the fleece bag will last all day sucking drywall dust you haven’t done your homework

Warren – There are situations where fleece bags make sense even with drywall dust. The point of these tests is to have fair comparison side by side.

Great review! I’m considering purchasing one of these dust extractors, and your comparison has been very helpful in making my decision. Thanks for sharing!