Best Construction Levels – Level Head to Head

48 Inch Construction Level Head to Head Comparison

Who makes the best construction levels? In this head to head we’re putting several 48″ construction levels to the test to see who makes the best!

One of the most fundamental tools required by all trades in construction is a level. Whether you’re building something plumb and level, or sloped, the only way to verify the slope of any surface is with some type of level. 48 inch construction levels are the most predominantly used size of level in the construction industry so we reached out to some of the leading brands and asked them to join our head to head comparison. For this comparison article we evaluated 7 different levels from 4 different manufactures. The manufacturers included:

- Empire Level

- Irwin Tools

- Stabila

- Stanley

While there are certainly many other level manufacturers to choose from we think this is a great assortment of levels. Over the last few months we’ve used these levels on job sites and tested them in the shop. The evaluation and testing was performed by three members of the Tool Box Buzz crew including myself, Rob Robillard and Jeff Williams. This evaluation consists of the following sections:

- Features and specifications

- Fit, Finish and Quality

- Vial Visibility

- Strength Testing

- Durability Testing

- Accuracy

- Cost & Value

48 Inch Construction Levels – The Lineup

The seven levels that we tested included the following (in alphabetical order):

- Empire Level – e75 Series 48″ TRUE BLUE® Box Level – Model E75.48

- Empire Level -e95 Series 48″ TRUE BLUE® UltraView™ LED Box Level – Model E95.48

- IRWIN Tools – 2000 Box Beam Level – Model 1794077

- IRWIN Tools – 2500 Box Beam Level – Model 1794067

- Stabila – Heavy Duty Level Type 196 – Model 37448

- Stabila – R Beam Type 300 – Model 41048

- Stanley – 48 in FATMAX® Premium Box Beam with Hook – Model FMHT42400

Six of the levels are box levels and one is a “beam” type level (which is still a box in our opinion).

Empire e75 Series TRUE BLUE® Box Level Features

- Reinforced vial locking system secures acrylic block vials and delivers long life accuracy

- Tool-free removable, shock absorbing endcaps provide superior protection and scribing performance

- Precision milled edges for guaranteed accuracy

- Surface grippers prevent the level from sliding on flat or angled surfaces

- Ergonomic, grip zones enhance comfort and portability (48”+ only)

- High contrast e-BAND™ vials highlight the edge of the bubble

- 300° Viewing Window maximizes range of view

- Hang hole for ease of storage

- Powerful rare earth magnets provide superior holding strength (magnetic models only)

- .0005″/inch Accuracy in all working positions

- $50

- Limited lifetime warranty

Empire Level -e95 Series 48″ TRUE BLUE® UltraView™ LED Box Level Features

- Concentrated, Surround Dual LEDs and UV Activated Optical Brightener provide superior vial visibility

- High contrast e-BAND™ vials highlight the edge of the bubble

- Reinforced vial locking system secures acrylic block vials and delivers long life accuracy

- IP54 rating protects level from dust and water

- Powerful rare earth magnets provide superior holding strength (magnetic models only)

- Tool-free removable, shock absorbing endcaps provide superior protection and scribing performance

- High contrast vial surrounds improve vial visibility

- Precision milled edges for guaranteed accuracy

- Surface grippers prevent the level from sliding on flat or angled surfaces

- 2X Longer Battery Life – up to 32 hours. (2) AA batteries included

- Automatic Shut-off saves battery life by turning off LEDs after two minutes

- .0005″/inch Accuracy in all working positions

- High impact acrylic e-BAND™ block vials offer superior durability

- LEDs flash when battery is low

- Ergonomic, grip zones enhance comfort and portability (48” only)

- Press to toggle LEDs between level and plumb positions

- Hang hole for ease of storage

- $75

- Limited lifetime warranty on frame and vials. 1 year warranty on electronics

IRWIN Tools – 2000 Box Beam Level Features

- Continuous Edge increases level durability ensuring accuracy over time, protects center vial, and allows for continuous scribing

- Plumb Site® offers dual-sided, undistorted viewing in the plumb position and easy, more accurate plumb readings

- Retractable end caps allow for scribing into and through corners, increasing work efficiency

- $46

IRWIN Tools – 2500 Box Beam Level Features

- Thick-walled high-grade aluminum frame provides extreme durability and resists jobsite wear and tear

- Continuous Edge increases level durability ensuring accuracy over time, protects center vial, and allows for continuous scribing

- Plumb Site® offers dual-sided, undistorted viewing in the plumb position and easy, more accurate plumb readings

- Over-molded rubber end caps provide shock-absorption, protecting the level’s accuracy upon impact, and are removable for accurate leveling into corners

- $76

Stabila – Heavy Duty Level Type 196 Features

- Crystal clear vials readable in any direction with no change in accuracy tolerance.

- Spring steel hairline indicators in vials.

- Locked vial system, no recalibration needed

- Removable rubber end caps for scribing in corners and for reading tight header and sill openings.

- Rubber end caps grip walls and do not leave marks.

- Metal Hang hole for storing level on site.

- Two rubberized hand holds for comfort and grip (16″ version has one hand grip)

- 59″ and longer have a bridge over the vial for increased strength as well as providing an uninterupted surface for both drawing and scribing over the horizontal vial

- Vials accuracy is guaranteed for life

- One Horizontal (level) and Two Vertical (plumb) Vials

- $130

Stabila – R Beam Type 300 Features

- Ergonomic, user friendly shape

- Precision: 3 Straight Edges

- Grip: Continuous Handle

- Finish: Fender Smooth

- Strength: Over 2X the horizontal strength of our Heavy Duty Type 196 levels

- Locked Vial System – Never needs adjustment

- One Horizontal (level) and two Vertical (plumb) vials

- 48″ Model offers an offset plumb vial for easy viewing from the kneeling position

- Vials are guaranteed for life

- $106

Stanley – 48 in FATMAX® Premium Box Beam with Hook Features

- Magnified center block vial for high readability accuracy .0005-in

- Block plumb vials for accuracy of .0005-in

- Removable end cap for flush and accurate markings

- Fold out rafter hook – on-site convenient storage solution

- $36

Fit, Finish & Quality of Levels

The first impression of any tool that we test is usually the fit, finish and quality of the materials used in the tool. First impressions are important and often help us gauge long term life and performance on tough tasks. While this is quite subjective, we have no doubt that most people would likely rank these in the same order if the levels were all laying on a bench in front of them at the same time. Below is the list of levels with the top of the list being the best fit, finish and quality.

- Stabila – Heavy Duty Level Type 196: This level really stands out among the levels in this evaluation. This is a very heavy duty level built from quality materials. It features a quality paint finish, milled faces, and very comfortable hand holes.

- Stabila – R Beam Type 300: While the Type 19 is our preference with the hand holes, this level is just as nicely built as the other Stabila level we evaluated. This level is certainly built to withstand the most severe jobsite conditions for trades like concrete and masonry.

- Empire – e75 Series 48″ TRUE BLUE® Box Level: The Empire levels also impressed us with the paint finish, milled faces, comfortable hand holes and quality vials.

Flatness of Milled Faces

For this section we also evaluated the flatness of the milled surface on the levels. To do this we placed a machined straight edge on each level and checked for gaps between the two surfaces using feeler gauges. All of the level contact surfaces were very flat. The largest gap between the machined straight edge and a level was 1 100th of an inch. The bottom line is all of these levels come with a very flat surface to start with.

Both the IRWIN and Stanley FATMAX levels are decent levels but more of a consumer grade with regard to fit and finish.

Vial Visibility

One of the key features of a good level is the visibility and readability of the vials. Five of the seven levels in this evaluation use a traditional yellow/green spirit color in the level vial. While two of them (Empire) uses a slightly blueish colored spirit in theirs. After using all of these levels over the past several months we feel the yellow/green color is preferable in most low light conditions. However, the Empire LED lighted vials are very easy to read and definitely a step above the green/yellow non-lighted vials.

In addition to the visibility of the actual vial, the placement of the vial within the level frame also contributes to the overall visibility of these levels. As you can see from the adjacent photo, each of the levels have the vials attached to the frame in much different positions. For example, the IRWIN and Stabila R Beam levels have cut-outs in the frame that creates a “window” to the vial. Whereas the remaining levels have a full notch at the vial allowing for greater visibility of the vial.

Frame Strength Vs Vial Visibility

Obviously the trade off is a strength vs visibility issue. The first three levels mentioned provide a stronger continuity to the level frame and additional protection for the vial. While the other levels provide far superior visibility from different user positions.

From our perspective, the Stabila Heavy Duty Type 196 offers the best visibility to the vial, and the clearest vial with it’s traditional Yellow/Green spirits. We also think the Empire LED has excellent visibility when using the LED light. The Stabila R Beam has the same vial but it’s much harder to see in the small “window” cut-outs vs the full view that the Type 19 offers. The flip side of this is the Stabila R Beam offers superior vial protection for tough jobsite conditions.

IRWIN Tools offers a unique design with an angled mirror built into the frame. This allows users to read the vial from other positions angles. This is extremely useful when working on ladders and other positions that make it difficult to see the vial.

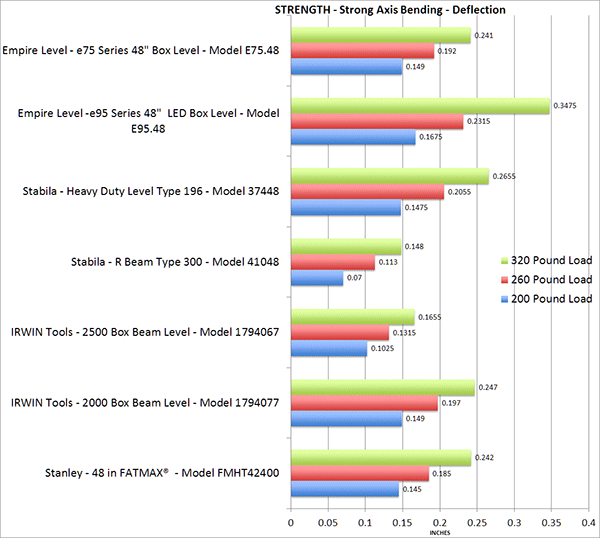

Flexural Strength in Strong and Weak Axis

In order to evaluate how strong these levels are we set up a test rig that allowed us to test the bending strength of these levels in both the strong and weak axis. While we didn’t test them to failure, we did load them with a heavy load and measure the deflection, which allowed us to rank them for flexural stiffness.

The test was a simple point load bending test. The load was applied to the middle of each level using a sling. A 2nd level was placed on top of the testing level to create a reference point to allow for deflection measurements. A sample of the test setup is shown below for reference.

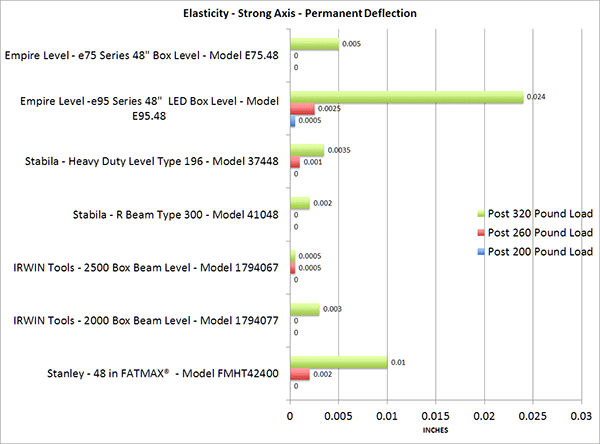

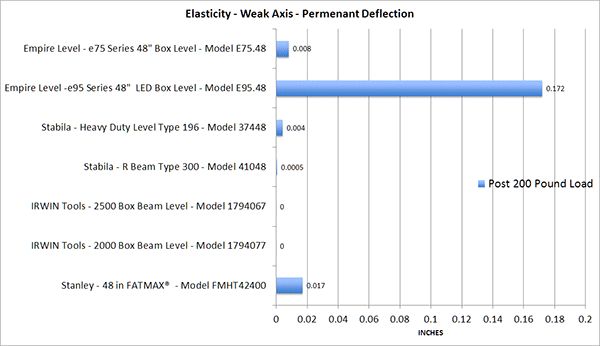

We also wanted to test the levels to see if any of them were permanently deflected after loading. We measured the difference between the initial no load state and the post load state. In other words, how well do the levels return to their normal shape after the load is removed. We measured this using a feeler gauge. That gives you an idea how small the numbers were.

The loads we applied on the strong axis were in the form of 60lb bags of concrete (3, 4, or 5 bags), plus the weight of the chain/straps, and plus the weight of the pallet. That gave us roughly 200, 260, 320 lb point loads tested on the strong axis and 200 lb load on the weak axis. The results are below:

Strong Axis Stiffness

The first graph above shows us the deflection of each level when loaded in the strong axis. The strongest (stiffest) level was the Stabila R Beam Type 300 with about 3/16″ deflection under a 300 lb load. Following in a close 2nd place was the IRWIN Tools 2500. Coming in last place was the Empire e95 LED level (the vial housing cracked under this loading condition).

Strong Axis Load – Permanent Deflection

We also measured permanent deflection after the load testing to see if any of the levels would be damaged (no longer straight) due to excessive loading. The graph above shows the measured permanent deflection of each level after the load was removed. Two of the levels showed a deflection that in our opinion would be considered significant. The Empire e95 was the worst one and this is almost certainly related to the cracked vial housing after the 300 lb load. The other level of concern was the Stanley FATMAX. It should be noted that these are still very small numbers with the Empire at 0.02 inches and the Stanley at 0.01 inches.

Strong Axis Load – Permanent Deflection

We also did the same comparison of the weak axis loading permanent deflection. Above you can see the same two levels didn’t fair very well under extreme loading in the weak axis.

So what does all this mean? Ideally no one is “loading” their levels in this fashion. However, it does give us insight into long term durability due to tough jobsite conditions. It gives us insight into how strong these levels are and how well they can take punishment when we abuse them.

Durability Evaluation – Drop Test

Levels are dropped from ladders, scaffolding, and all over the jobsite so we wanted to evaluate how well the levels performed after being dropped from a fixed height. This test was again used to rank the levels based on their post drop evaluation. We built a rig so that the levels would all be dropped in the same way. Jobsites are all so different that there are probably a few thousand (maybe more) combinations of heights, vectors, and surfaces that levels could be dropped. We chose to drop them straight down as a way to best evaluate the end cap protections engineered into the levels.

Levels are dropped from ladders, scaffolding, and all over the jobsite so we wanted to evaluate how well the levels performed after being dropped from a fixed height. This test was again used to rank the levels based on their post drop evaluation. We built a rig so that the levels would all be dropped in the same way. Jobsites are all so different that there are probably a few thousand (maybe more) combinations of heights, vectors, and surfaces that levels could be dropped. We chose to drop them straight down as a way to best evaluate the end cap protections engineered into the levels.

The drop rig was an 8′ step ladder with a 3″ ABS tube positioned vertically. A trigger pin (long, smooth bolt) was drilled through the pipe section and the lowest point of the level was right at 6′ above the ground. We pulled the pin and dropped them 10 times each and then inspected for physical damage as well as retested for accuracy. The accuracy results are below. A number of 4 for plumb means that the vials read plumb in 4 directions and that the vials were unharmed by the drops. A number of 2 for level means that the vials read level in 2 directions and that the vials were unharmed by the drops. Anything less that than means the vials moved over the course of the drops.

Drop Test Results

After each level was dropped we checked them to see if the vials were still working properly. The results are as follows:

- Six of the seven levels all read plumb from both ends of the level. The Empire e95 only read plumb from one end.

- Four of the seven levels all read level after the drop test including:

- IRWIN Tools 2000 Box Level

- Stabila R Beam Type 300

- Stabila Heavy Duty Type 196

- Empire e75 Level

- Three of the seven levels no longer read “level” after the test including:

- Stanley FATMAX

- IRWIN TOOLS 2500 Box Level

- Empire e95 LED Level

In addition, we also inspected the damage to the protective end caps. Most did very well in this evaluation with the exception of the IRWIN Tools levels. These levels could benefit from redesigned end caps.

Level Accuracy

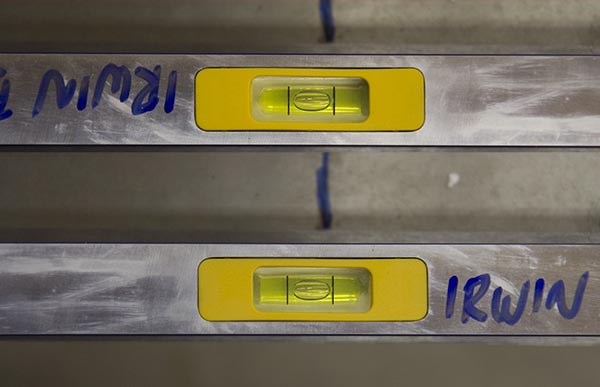

Accuracy is obviously important with construction levels. We performed a basic evaluation of the levels to check accuracy. The test involves placing the levels on a fixed surface in both directions and checking the level to see that it reads the same from both sides. Below is an image showing one of the tests. As you can see the bubble on this IRWIN Tools level show the same in both directions (bubble slightly to the right of center).

All of the levels passed this test and showed great accuracy “right out of the box”. We found no signs that any of the levels had an accuracy problem.

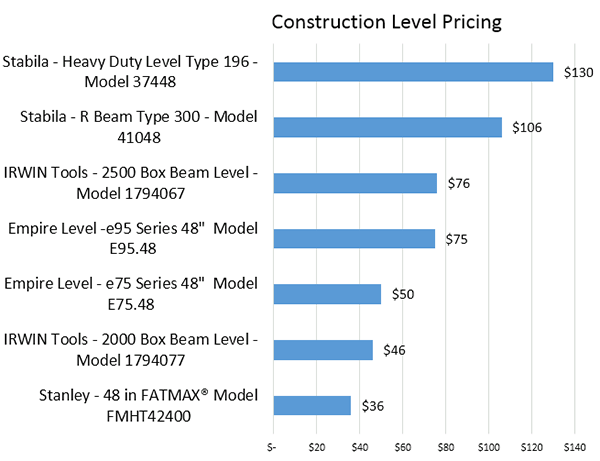

Value – Price & Performance

Value is very subjective for an evaluation like this due to the wide range of prices. So for this evaluation we felt it was important to consider the first three categories combined with the price of the tool. After all, if a level that costs half as much as a similar competitors level can withstand the same punishment and remain accurate, then that would be far more valuable from an investment point of view.

From our perspective the best value for this group of levels is the Empire e75 Series 48″ Model E75.48 level. Priced at $50 it’s a very well built level costing less than half of the Stabila levels that we tested. It performed well in our durability testing and it offers excellent accuracy. Honorable mention in this category goes to the IRWIN Tools 2500 Box Level coming in at $76 dollars.

Unique Features

Levels have been around for a very long time so what could possibly be unique about a level? We love innovation and several of these levels have some unique features that are worth pointing out.

- Lighted Vials – Probably one of the most innovative features we’ve seen are the lighted vials that Empire is using in their TRUE BLUE® UltraView™ LED Box Levels. This feature comes in handy more often than you might expect. Working in dark areas like basements, crawl spaces, attics, and low light situations makes the LED feature invaluable. This is a feature that we feel will end up on lots of levels in the future. The LED light is turned on by pressing a button on the side of the level. The LED turns off after 2 minutes automatically. The LED runs on two AA batteries for up to 32 hours.

- Rafter Hook – Who doesn’t love a rafter hook on their tools? We’re used to them on our power tools and expect them on quality tools to help with working at heights. The Stanley FATMAX® Premium Box Beam Level offers a unique fold out rafter hook on one end of the level. Anyone that’s framed a roof knows how handy this can be, preventing the level from sliding off the roof! We think this is an awesome feature to include in all levels for carpenters.

Overall Results – Best Construction Levels

At the end of the day we all want a winner and a trophy right? Well this comparison sure was tough to do (those of you who have followed this head to head on Social Media should know how hard it was by the time it took to write it!). For this head to head we’ve decided to highlight three of the best construction levels:

- Best Construction Level – Hands down we felt the Stabila Heavy Duty Level Type 196 was the best level that we tested. The quality, strength, visibility, and accuracy of this level make it easy to name as the best construction level that we tested.

- Best Construction Level Runner-Up – Again Stabila takes the nod on this one. This time we’re naming the Stabila R Beam Type 300 as our Best Construction Level Runner-Up. The quality, durability, and strength of this level make it a tool that sure to last for years to come.

- Best Value Construction Level – The Empire e75 Series 48″ Model E75.48 level really impressed us with it’s quality, accuracy, and durability at a price that’s well over half that of the levels listed above. This level certainly deserves to be ranked very close to the two Stabila levels that we evaluated.

About the author

30 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

I thank you for your hard work in compiling this report. It’s obvious that you left no stone unturned.

For those of us that are in the masonry trades and lean towards tor Mahogany or laminated wooden beam design with metal edges, a similar test would be valuable. I realize these units may be totally different and in some cases considered a lesser grade product, but I could tour you through many a high profile, level & plumb structure, that was built with a wooden level. I personally prefer the Crick but the Mahogany, brass edged units are sound, and as is the case with any tool, proper care yields true results.

I thank you for your hard work and especially for this web site.

Respectfully,

Ross H. Holmes

Please explain why you prefer a wood level over extruded aluminum. You don’t need to oil aluminum, you can get it as wet as you want, you don’t need to adjust most, one vial is as accurate as two and can not provide a lifetime warranty

. As far as I know, there is no advantage to wood levels except tradition.

Metal dents and bends…. Wood and bamboo have much more “Give” for us that work with cementitious building materials. In other words If you don’t do masonry or concrete work you can’t understand, nor will you.

Oh we do understand and respect that.

Lol come on man no ones using all wood in the concrete game. Chill w that.

One thing about the rubber bumpers , they offer drop protection , but not the option to strike an accurate line in an inside corner.

Due to the taper , a pain for real world speed ,to have to transfer the line back to the corner with a straight edge.

That’s why some levels have the end cap removable without tools. Something that could maybe added to this review. Great point

One issue w/ a number of levels is that the milled edges are chamfered, which can make it difficult to strike an accurate line, especially when you can’t see the line you’re trying to draw. My preference is for a level with a very, very small chamfer. For some reason milled edges on aluminum are very sharp, so you need to break the edge, but it shouldn’t be more than a 64th. This issue isn’t addressed in the write-up.

Bob – Interesting feedback. Would love to know the line of work you’re in. As framers I never really think about such precision. In my wood shop I use a machined straight edge for finer work. Thanks for sharing..good stuff!

I’m a retired engineer turned professional handyman. I’ve heard a couple of other people express the same concern. The job where I got so frustrated was installing a drop ceiling in a laundry room, trying to transfer a line around the room for the wall moulding. Next time, doing a basement bathroom, I used a cross beam laser- worked a little better. Both times, I’ve been glad I used an acoustical ceiling, because both times, the pipes above have needed repair- it made cleaning up after the plumber a bit easier.

You could find the high point on the floor and measure up the ceiling height there and use a 4’ level to make a guide line, then attach wall molding at that point follow your 4’ line fasten to wall then lead with a l2 or 4’ level.

The cross hair laser is the way to go it comes with a clip for wall molding

I too have found the chamfered edge on some levels annoying. In remodeling work, like extending a line of cabinets or installing single cabinets in baths, laundry rooms, etc., breaking out the laser is impractical. Striking a line is quicker and simpler, and trying to keep the pencil at a consistent angle to the level when it’s edge is chamfered is challenging at best. A square edge on the level really helps in these situations. I’ve sometimes resorted to using a cheap 48″ square edge level checked for trueness with a quality 24″ level held together to draw the line.

I have a laser pointer built for leveling conduits and pipes, patented. I was wondering how I would get some of these companies to look at for marketing and building. Do you know how I would go about this or who I could contact. The company I had help me patent this has not done a good job marketing it and I would really like to get moving on it.

Hi Jake, did you have any success with your approach? I too

have invented a a rather unique level, not at all similar to yours. Thanks, Darren

First let me say you guys rock at test. But with the table test yall went to the extreme testing precision plate on a surface plate. My question is why not use a test indicator and the surface plate and test the straightness claim. AlsoHow does the empire 75 and the Milwaukee fair against each other.

Javier – We looked at straightness using a machine edge. The empire is a great level, but I’d say it’s a slightly less “robust” design, and it’s a lower price point.

Stabilia lights have not worked right since the first week! they replaced them but they never work for more than a week or two. they told me to not call them about the lights anymore and that they will not honor the warrentee on my levels anymore! what kind of company would do that! I had only called them twice! I love the levels when the light worked but they never do when I need it to.

you didn’t test Johnson levels. why not?

They didn’t supply samples for the testing. We reach out to all the manufacturers and invite to them to join.

As a master carpenter with over 35 years experience, I am really disappointed in this incomplete article. The title of this article suggests that you are going to find the best construction level. You didn’t say anything about “best construction levels on a budget” either. You list the Stabila Heavy duty type 196 for $130.00. You mention that there is a 16″ model and a 59″ model. So does that mean I can buy the 59″ for $130.00? And do I really have to pay $130.00 for a 16″ level? You do the math. Also, you failed to include any of the best construction levels available to include Crick levels, Smith levels, and even Sands wood levels. The only level that you recommended in your list that I would consider a professional grade level is the Stabila levels. I would appreciate if you would do diligent research before writing an article about the most important tool in a Carpenter’s arsenal.

Todd – If you’ve been following our site for any amount of time, more specifically our Head-to-Head articles you’d like know we invite many Brands to participate in our evaluations. We don’t make money doing this so we rely on getting product donations from those willing to participate. So we are listing what we feel is the best from the group we review. You’re certainly entitled to your own opinion but there is value in this article to those looking for a comparison of the tools we tested.

While not exhaustive (darn you, Johnson for not responding), there is PLENTY of value in this. Like many others, I genuinely appreciate the methodology and attention to the significant details. Even if I don’t choose a level from this group, I have specific criteria to pursue. Thanks for creating this.

This was a great article. Yes, we may have wanted some other brands in the line up but I understand that companies may not want to participate. In any event, keep up the good work!

Thanks for a very helpful article! Stabila was recommended to me by a carpenter with 40 years experience but then I saw a couple comments/customer reviews online expressing concern about flimsy construction / inaccuracy out of the box for some Stabilas. Thank you for providing the analysis to put that to rest at least for the 196..and for saving me hours of research online trying to develop an informed view about all the other available options in the test. Really appreciate it!

[…] crew here at Tool Box Buzz took a look at some of the top offerings for Best Construction Levels Head to Head a couple years ago. The criteria the crew used to evaluate those levels, reads like the features […]

the only problem in every situation that a level is needed, is that all levels can be off. just like every tool made, the tolerance is never noticed until its beyond acceptance. Charlie left me a wood level, I’ve purchased 10 aluminum but the only real 72″ that has lasted the test of time is the craftsman i bought when i was a first year apprentice. belive it or not its still the best i own. I began this exploration looking for my next awesome level. looks like ill be using craftsman. I cant believe i am saying that. Once in a while you find a jem, doese;nt matter what its made of. Chicago, IL 51yr old. life long carpenter

Traditionally the wood levels were used by masons after alloy levels came along. Mortar and plaster stick to aluminum like nothing else, and mohogany is fairly stable around water.

Stabila or MD levels are all the same to me. You cant tune them. The only thing worse than a non adjustable level is a plastic level from home depot, lowes etc. I go on job sites today where there are problems. I ask, let me see your level, I check it and it out an 1/8″ to 1/4″ in 4′. The biggest problem with any level is the mechanic who does not know how to use it and refuses to learn.

Maybe articles on how to measure various critical things would be more useful.

I know I’m late to this feed. I appreciated this review. Very helpful. One thing: Under “Strong Axis Load – Permanent Deflection” you say, “The Empire e75 was the worst one…” I believe you mean the e95. Is this not correct? Perhaps it could be corrected for accuracy.

Thank you!! We fixed it.