Impact Driver Head to Head

Best Impact Driver – Head to Head Evaluation

There’s no doubt that Impact Drivers have completely changed the construction industry and drastically improved both productivity and quality. Impact drivers allow users to more quickly install threaded fasteners while avoiding damage to the fasteners. In our latest head to head testing we’ve selected ten full size impact drivers from a wide range of manufacturers. We invited all of the major manufacturers to participate and the ones included in this test are the ones that chose to participate.

We also decided to use only traditional impact drivers and exclude the new class of hydraulic impact drivers as those seem to be emerging as an entire class onto themselves. Our Impact Driver head to head included the following tools:

- Bosch Model IDH182B

- DEWALT Model DCF887B

- Hilti Model SID 4-A22

- Kobalt Model 672824

- Makita Model XDT12T

- Metabo Model SSD 18 LTX200

- Milwaukee Model 2753-22

- Porter Cable Model PCCK647LB

- Ridgid Model R86037

- Ryobi Model P237

Impact Driver Specifications

We’ve listed the basic specifications for these tools, a link to their web page, and the batteries that were used in the test.

- Bosch Model IDH182B: 18V Li-Ion, brushless motor, 3.2 lbs, 1/4″ hex and 1/2″ sq. drive socket ready, 6.0 Ah Core battery packs, 3 speeds: 0-2,800 / 0-2,000 / 0-1,300, Impacts per min 0-3,200 / 0-2,600 / 0-1,100.

- DEWALT Model DCF887B: 20V MAX Li-Ion, brushless motor, 2.0 lbs, 1/4″ hex, 5.0 Ah Bluetooth battery packs, 3 speeds: 0-1,000/ 2,800/ 3,250, Impacts per min 0-3,800. This model included batteries with the Tool Connect™ Bluetooth functionality for battery monitoring.

- Hilti Model SID 4-A22: 22V Li-Ion, brushless motor, 1/4″ hex, 5.2 Ah battery packs, 3 speeds, max impacts per min 3,500.

- Kobalt Model 672824: 24V MAX Li-Ion, brushless motor, 1/4″ hex, 2.0 Ah and 5.0 Ah battery packs, 3 speeds: 0-850, 0-2,000 and 0-2,700, Impacts per min 3,500 max.

- Makita Model XDT12T: 18V Li-Ion, brushless motor, 1/4″ hex, 5.0 Ah battery packs, 4 speeds: 0-1,100/ 0-2,100/ 0-3,200/ 0-3,600, Impacts per min: 0-1,100/ 0-2,600/ 0-3,600/ 0-3,800.

- Metabo Model SSD 18 LTX200: 18V Li-Ion, brushed motor, 1/4″ hex, 3.1 Ah battery packs, 3 speeds: 0-2,500 rpm, impacts per min 3,300 max.

- Milwaukee Model 2753-22: 18V Li-Ion, 3.1 lbs, brushless motor, 1/4″ hex, 5.0 Ah battery packs, 3 speeds: 0-850, 0-2,100, 0-3,000, impacts per min 3,700 max.

- Porter-Cable Model PCCK647LB: 20V MAX Li-Ion, brushless motor, 1/4″ hex, 1.5 Ah and 4.0 Ah battery packs, 2.9 lbs, speed 0-2,700 rpm, impacts per min 3,100.

- Ridgid Model R86037: 18V Li-Ion, brushless motor, 1/4″ hex, 2.85 lbs, 6.0 Ah Bluetooth battery packs, 3 speed: 0-2,750 rpms.

- Ryobi Model P237: 18V Li-Ion, brushed motor, 1/4″ hex, 2.75 lbs, 4.0 Ah battery packs, 3 speeds: 0-400, 0-1,100, 0-1,800.

Impact Driver Evaluation Criteria

When we set out to do a head to head test for power tools the toughest decisions to be made are deciding what our evaluation criteria will include. There are endless testing situations for any tool so we discuss the tool in question and try to develop tests that we feel users can relate to.

For this evaluation we did NOT consider run-time. While many of you might find this frustrating, our perspective on run-time justified this decision. We feel that most of the major tool brands that are offering a full size impact driver are using good lithium-ion battery packs along with brushless motors. Because of this, in most situations these tools will run long enough for the average worker to complete his or her work in a standard work day. Furthermore, if the user owns two battery packs, it’s extremely unlikely they will drain one battery before the second one is charged and ready to work.

For this head to head we decided to focus mostly on productivity. In order to do that we looked at several common uses for impact drivers and the speed in which they operate. The tasks in these tests are common tasks that our crew perform on a regular basis, so for us these are a great indication of how productive these tools can be. For this head to head we developed the following tests:

- 3″ Deck Screws – Average Drive Time in Pressure Treated Southern Yellow Pine

- 3/8″ x 3″ Lag Bolts – Average Drive Time in Pressure Treated Southern Yellow Pine

- 5″ TimberLOKs – Average Drive Time in Pressure Treated Southern Yellow Pine

In addition to productivity testing, we also wanted to get a relative comparison on power and applied torque. Torque testing is difficult to do and we don’t own any fancy lab equipment so we decided to do some static torque testing. For this test we tightened a 1/2″ bolt and nut assembly onto a 1/2″ thick piece of steel for 6 seconds. After applying the torque with the impact driver, we then removed the nut using a digital torque wrench set up to measure the maximum torque applied. We did this same test 5 times for each impact driver and reported the average torque.

The last part of our evaluation included ergonomics. For this evaluation the entire test group sat down and evaluated all of the impact drivers that were used during the test. With everyone on the team using impact drivers differently throughout or normal work day, this was a great way to develop a consensus on which tools we felt were the most comfortable for users.

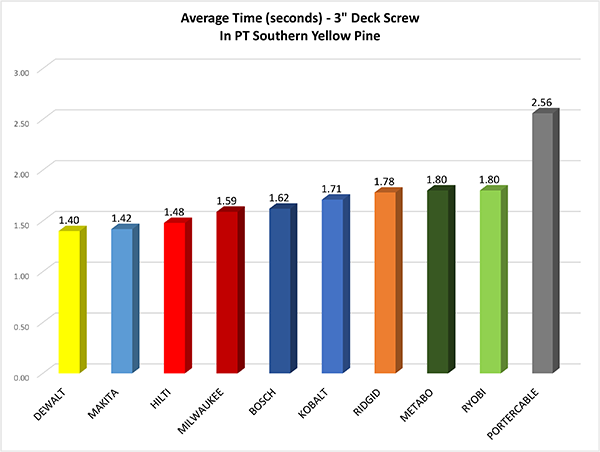

3 Inch Deck Screw Testing Results

WINNER: DEWALT DCF887B

The first test we performed included the same user installing 3 inch deck screws into pressure treated Southern Yellow Pine. This is a task that we feel many of our readers do on a regular basis and it highlights a task that can benefit from improved speed of installation and ultimately productivity gains.

We took the average of 5 fastener installations. We had the same user do this test for all the impact drivers to minimize any chance of time being affected by a different user. The following chart shows the results of this test:

As you can see in the chart above, DEWALT had the fastest average time to fully drive 3″ deck screws in pressure treated Southern Yellow Pine. Makita was a close second followed by Hilti in third.

It should be noted that the top three impact drivers only had a difference of 8 hundredths of a second which isn’t a very big difference. While hundredths of a second won’t likely change the overall productivity of a user over a full days work, some of the others that are slower by tenths of a second could add up to some significant time over the course of a full day.

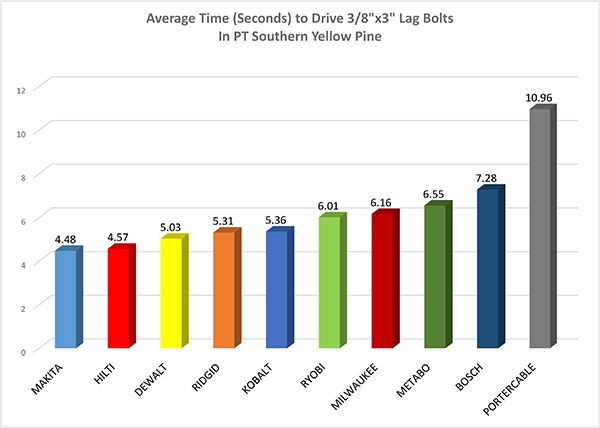

3/8 x 3 Inch Lag Bolt Testing Results

WINNER: Makita XDT12T

The next test in our evaluation was done by installing 3/8″ x 3″ lag bolts into pressure treated Southern Yellow Pine. Lag bolts are still a popular fastener used for decks and timber framing so it’s a logical choice for impact drivers. Again we took the average of 5 fasteners installations performed by the same person for all the impact drivers.

As you can see in the chart above Makita had the fastest average time to install the 3/8″ x 3″ lag bolts in the pressure treated Southern Yellow Pine. Coming in a close second was Hilti followed by DEWALT in third place. The results for this test were certainly more spread out than the deck screw test and there’s clearly an advantage in productivity for users of the top impact drivers when it comes to installing heavier fasteners like lag bolts.

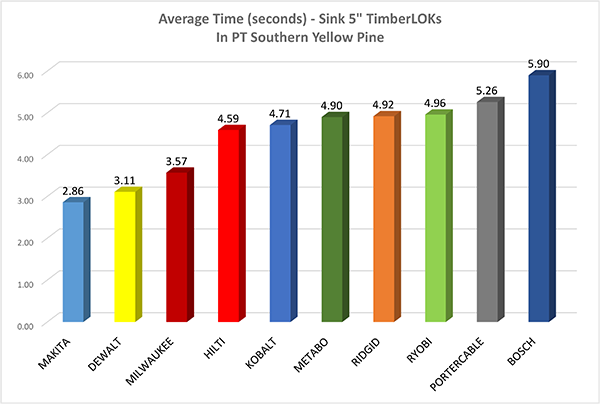

5 Inch TimberLOK Testing Results

WINNER: Makita XDT12T

The next test was done by installing 5″ long TimberLOK’s structural bolts into pressure treated Southern Yellow Pine. With today’s advancements in engineered lumber these fasteners have become standard on almost all wood framed projects. Impact drivers are the perfect tool for this application so it’s a great evaluation. Again we took the average time to install 5 TimberLOK’s by the same user.

As you can see from the chart above Makita really excelled at this task. Coming in second place was DEWALT and Milwaukee followed them in third place. The top three have a very big advantage over the rest of the field with this test which results in huge productivity advantages for the end users.

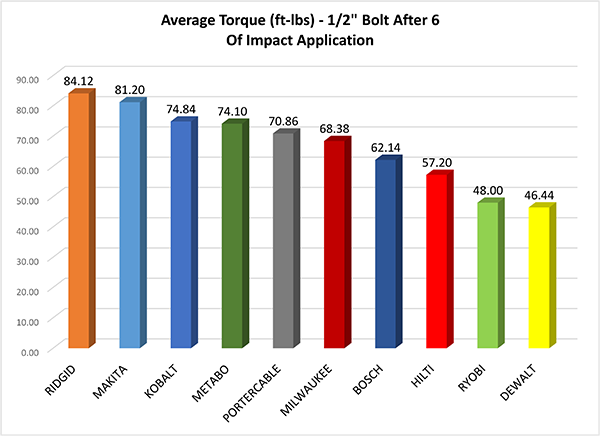

Static Torque Testing Results

WINNER: Ridgid R86037

The final test that we performed was a static torque test. In this test we applied torque to a 1/2″ bolt and nut assembly attached to a steel plate. The torque was applied for 6 seconds at which point the impact driver was removed. We then removed the nut using a digital torque wrench meter. The meter allowed us to measure the peak torque measured as the nut was being removed. Again we took the average result from 5 installations by the same person.

As you can see above Ridgid was the winner with the highest torque required to release the nut. Second place went to Makita followed by Kobalt in third. These results are a bit intriguing when you look at some of the tools that ended up at the back of the pack. However, these are impact drivers and NOT impact wrenches. So does the lack of peak torque matter as much? We think it’s a balancing act and for more applications like deck screws, small lag bolts, and even structural fasteners all of the impact drivers have more than enough torque.

Ergonomics Evaluation

Ergonomics is the most difficult evaluation we ever do because it’s such a subjective process. We evaluated the size of the impact driver, weight, balance, grip comfort, LED lighting, and functionality of controls. For this evaluation there were six reviewers with input and feedback for each of the tools. For this category we’re naming the top three tools based on the overall consensus of the group.

- MAKITA – The Makita XDT12T is by far the most compact of the impact drivers that we tested and the entire group felt it had one of the most comfortable grips. Due to the short length of the head assembly, this is a very well balanced impact driver with easy to use controls. The only thing that we didn’t feel was up to par was the LED lights which we’d like to see in a better location.

- HILTI – The Hilti SID 4-A22 was definitely one of the most comfortable impact drivers we tested. It’s sleek design and lack of appendages make it less likely to snag on things while working and definitely less likely to be damaged. This impact driver is very well balanced and offers great lighting with 4 LED’s around the housing.

- DEWALT – The DEWALT DCF887B has the most comfortable grip of all the impact drivers. This impact driver is also well balanced and offers 3 LED lights around the housing for great visibility. The only negative for this one was some “slop” between the battery and receiver.

Impact Driver Pricing and Value

It’s always hard to compare the pricing of cordless tools especially when each manufacturer packages them differently with kits, bare tools, and then varying size batteries.

- Bosch IDH182B: This was not a kit. This was bare tool ($117), two 6.0 Ah battery packs ($246) and a charger ($59) for a total as tested price of $422.

- DEWALT DCF887B: This was not a kit. This was bare tool ($129), two 5.0 Ah Bluetooth battery packs ($140) and a charger ($79) for a total as tested price of $348.

- Hilti SID 4-A22: This was sent as a kit which includes the impact driver, two 5.2 Ah 22 volt battery packs, charger and soft bag for a price of $399.

- Kobalt 672824: This was a kit plus an extra battery pack. The kit includes the impact driver, soft bag, charger, and 2.0 battery pack ($159). Kobalt also sent us a 5.0 Ah battery pack ($89) for a total as tested price of $248.

- Makita XDT12T: This is a true kit containing the impact driver, hard box, charger, and two 5.0 Ah battery packs and it costs $349.

- Metabo SSD 18 LTX200: This was another true kit with a hard case, impact driver, charger, and two 3.1 Ah battery packs priced at $310.

- Milwaukee 2753-22: This is another true kit featuring hard case, charger, impact driver and two 5.0 Ah battery packs selling for $299.

- Porter Cable PCCK647LB: This is another kit featuring a soft bag, charger, impact driver and two 1.5 Ah battery packs selling for $139. They also sent us two 4.0 Ah battery packs to better align with the competition and those sell for $94 each.

- Ridgid R86037: There wasn’t a kit for this one so they sent us the bare tool ($99), charger ($79) and two 6.0 Ah Bluetooth battery packs ($129 each) for a total as-tested price of $436. **NOTE: The $129 price is an estimate as the 6.0 Ah packs are not in stores yet and that price may change. The packs should show up in stores at the end of 2017.

- Ryobi P237: There wasn’t a kit for this one so they sent us the bare tool ($79), a charger ($50), and two 4.0 Ah battery packs ($99) for a total as tested price of $228.

When you consider the pricing above along with the performance we feel the Milwaukee FUEL kit is the overall best value at $299 which includes two 5.0 Ah battery packs. The value of the Makita is also excellent at $349 and you get the winner of several of our tests!

Overall Best Impact Driver

We always struggle with announcing the overall winner especially when there are so many great power tools available today. It’s also important to note that we are making these judgements based on the criteria that we have laid out above, which in some cases might not be the criteria you would use.

When ranking the test data from above and also considering the ergonomics and pricing the following are our top three impact drivers:

- First Place: Makita XDT12T – The Makita impact driver really did blow away on the competition for the tests we performed. In speed tests, it won both the 3/8″ lag bolts and the TimberLOKs, and came in second for the deck screws. It also came in second place for the static torque testing. We also felt it was the best when it came to overall ergonomics. Priced at $349 including a hard case this is an exceptional impact driver.

- Second Place: DEWALT DCF887B – The DEWALT did very well in our testing as well. It finished first in deck screws, second in the TimberLOKs, and third in the lag bolts for speed testing. While it finished last in the static torque testing, it’s worth noting that it has no trouble with any of the other fasteners we installed so the tool clearly supplies more than enough torque to get the job done. When it came to ergonomics it finished third and offers one of the most comfortable grips in the market. Priced at $348 without a case this is also an excellent impact driver.

- Third Place: Hilti SID 4-A22 – The Hilti impact driver also did very well in our testing finishing second in the lag bolts, third in the deck screws and fourth in the TimberLOKs. Its sleek design earned a second place in ergonomics and it finished in the middle of the pack for the static torque testing. This unit is priced at $399 and it includes a soft bag making it another very good impact driver.

Final Thoughts – Full Size Impact Drivers

This was such a fun evaluation because the field was so closely matched for the most part. While we picked several winners it’s worth noting that we made choices based on razor thin margins. For many users, the decision on which impact driver they should buy will likely be based on the battery platform they own.

The bottom line is this, almost all of these impact drivers are very capable of performing most any fastening task for small and medium size fasteners. The Porter-Cable struggled to keep up with the competition, but it was able to perform all the tasks we did. If you don’t own an impact driver, or you’re still running a brushed version, do yourself a favor and get into one of these new brushless impact drivers!

Impact Driver Head to Head Video Review

About the author

33 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Nice review! it appears to me that the 3″ and the lags are a virtual tie for the first 9 and 6 respectively. I think at the end of the day it’s more likely going to be who drops the most screws/lags that gets less work done.

I’m curious on the 5″ what the difference is, higher IPM or RPM?

For the torque I’m not surprised the ridgid is tops there, it is rated at 2250 in/lb

and for the pricing, well it just doesn’t make sense, the ridgid is available in a kit with 2 4ah batteries, a quick charger, and a brushless hammer drill for $249. Or adding their brushless 7 1/4″ circular saw to all of the above for $399. at $249 it is within $25 of the cheapest and includes another tool.

Plus, lifetime service on all components, and lifetime batteries. and yes, I have the brushless impact, hammer drill, circular saw and due to the way I bought, (3) 4ah batteries.

With the warranty that Rigid offers I find it hard to beat. The batteries and the tool lifetime.

Exactly the reason I went with rigid! I have owned them all and my problem was exactly that, batteries. Never busted a tool but got tired of needing new batteries.

The Rigid lifetime service contract is hard to beat, but, recently they gave me a really hard time getting new batteries.

I have had bad luck with DeWalt batteries. On failed too soon after purchase and the replacement was DOA. They replaced the replacement free with no hassle.

Where do you see that for $249? I think the kit you’re talking about is the R9205 (here: http://www.homedepot.com/p/RIDGID-GEN5X-Brushless-18-Volt-Compact-Hammer-Drill-Driver-and-3-Speed-Impact-Driver-Combo-Kit-R9205/206127587 ) but it’s $279. That’s not a big difference at $30 more, but notable.

Razi – If you read the section you’ll see we priced it as a bare tool ($99), charger ($79), and two 6.0 Ah battery packs (not even available on the market yet). Not sure where you see $249?

Home Depot

I wonder why you guys did not include the Hitachi Triple Hammer, that would have been interesting to see where it placed. Thanks for the test.

We invited them…they didn’t send a sample.

Hi, inevitably, there is always the ‘what about product X?’ question.

So, at least broadly, what do you guys think about the hydraulic impacts?

The new hydraulics are really impressive, and in most applications of small and medium fasteners they are a better tool option. They are so quiet, they are fast, and they seem likely to last longer.

Kick ass job guys. This is the type of information I would be looking for when making a purchase decision.

Thanks John!

I always wonder about comparison to corded tools. Yes, I know you dont have the same portability, but many times the corded tools are just better.

Any thoughts on the corded Makita 6952 2.3 Amp Impact Driver

—

John C

John – Quite honestly, almost all of the major manufacturers now manufacture cordless tools (drills, impact drivers, etc) that perform as well or better than the old corded versions. It’s just not an issue these days with the smaller tools. In fact, many of the larger tools (rotary hammers, saws, etc) are now in the same category as well.

I get what youre doing. Dont get me wrong and i enjoy this videos and reviews.

What i would like to see is you put these on a jobsite and after time come back and the same review and see how they stand up. Its great seeing the batteries and tools operate right out of the box. But that only happens once in a tools life. The rest of the time theyre being driven, beat up, dropped etc.

Lets see who the top 3 are in longevity, endurance,life,toughness,durability,etc.

I realize this involves more time from you the reviewer but if you want to be a true influencer you should try to deliver on the lifespan of our tool investments. Break out of the box

I like that idea. A number of times we’ve done follow-up long-term reviews either in long form on the website or quick updates on our social media channels. The problem with doing something like that on a review of one of the big 4 tools, drill, impact, circ saw, recip saw, is that manufacturers update these tools more frequently than any other. They are on a replacement schedule of sometimes 2 years or less. The sku may still be available but it isn’t in the same league as the new offering.

Some tools it makes a lot of sense to simulate toughness and durability tests up front like we did with the 48″ level head-to-head. Other tools, by the time we put them through the exact same tests on the job site over a period of time, the review wouldn’t be relevant anymore. Many times after a day of testing, each guy takes one of the tools with them to use on their own job sites. They could all report back after say 3 months but they wouldn’t have all gone through the same usage.

We’re all ears though on how to make the content better. If you have ideas of how we could simulate the endurance, longevity, etc. by all means, let us know. Thanks for reading and thanks for commenting.

Great job on the impact driver test. I read comments about “why didn’t you do this” or “what about that?.” Your team did a great job overall testing the impact drivers.

Thanks,

Geoff

Thanks

All wood application? What about concrete screws and tek screws for thin gauge metal…more commercial construction applications. I say this because a company like a Hilti would be more focused on performance on those applications because they are more common on a commercial construction that deals with more steel and concrete vs wood applications.

any thoughts on the ridgid stealth force?

It’s a great impact driver, we just consider the oil pulse impacts a different sub-category.

There is one major issue which every tool test on battery tools will not discuss, the incompatability of batteries between brands. Let us be honest, no tool manufacturer produces the “best” tool in all types of tool it produces, drills, saws, planers, grinders, screw drivers etc. etc. I, like many other professional tool users make a conscience decision when buying, to buy what they consider is the best choice at the time regardless, of brand name. I am not a one brand tool owner and user. The tool manufacturers are trying to lock you into a one brand allegience by offering a number of tool skin deals but only one battery, which may be OK for the “home handy man”, but not for a person who derives a living from using tools. We now have the situation that within one brand there are a number of different types and voltage batteries which are not interchangable and are incompatable. the other issue with battery powered tools is that the greater capacity and performance increases the size and weight of the tool and are now weighing more than a corded tool. The other issue is that you have to have more than one battery for each tool and that means more than one battery charger. I have and use battery tools but I will continue to buy and use corded tools because they allow for a universal and constant power source and I have the freedom of brand choice, something which no battery tool manufacturer can provide.

Are you guys planning on doing a different test with just the hydraulic drivers (oil impulse)? Specifically the Milwaukee surge and makita soft impact. Or not any time soon? Thanks for the great impact driver test!

We’re waiting to see if anyone else releases oil impacts.

Excellent reviews! Before making a purchase decision this is the best information for everyone.

Great post! I am thinking of switching platforms from the Porter Cable to Dewalt or Ridgid. I feel like it would be a win win choice. Do you think PC is done for? Lowe’s is certainly not showing PC any love right now. Thanks, BamaDave71

It’s interesting. PC is owned by Stanley Black & Decker. They also just bought Craftsman which is now being sold in Lowes. I think DEWALT and Ridgid are certainly better options.

Have enough manufacturers released newer models to warrant and updated version of this head to head?

I would definitely be interested in that.

yes

Hello, Todd Fratzel. Great work guys! I think if you look at all the brands especially when you consider that an impact driver/drill driver is a gateway for many users to other skins the brand line up plays an ever-increasing role. Keep it up:)

My poor Porter Cable master race……..finishing last, but finishing none the less, lol.

I found your head-to-head comparison of different impact drivers incredibly useful. I’m curious, though, about the long-term durability of these tools. In your experience, which brand or model has shown the best resilience and longevity, especially under heavy use? Thanks in advance for your insights