Milwaukee M12 FUEL Generation 2

Milwaukee M12 FUEL Generation 2 – An Editorial

Bigger, Faster, Better – right?

Maybe . . . but I prefer Compact, Powerful and Better, that’s where the moneys at.

12-volt tools seem to have developed a “toy-like” stigma associated with them. People inherently think that 12V tools are NOT powerful enough for the work they do. That’s just not the case, and couldn’t be further from the truth. Here’s my take on 12 volt tools, and more specifically, Milwaukee M12 FUEL Generation 2 tools:

- Not everyone needs a larger, more powerful M18 tool as their primary tool.

- 12 Volt tools at not for DIY-ers anymore

- 12V tools are NOT inferior to 18V tools; it just depends on the application.

Milwaukee M12 Completely Redesigned with Gen 2

Milwaukee has completely redesigned several of their M12 tools to be capable of performing a wide range of applications in a smaller footprint, they are:

- M12 FUEL 1/2″ Drill Driver

- M12 FUEL 1/2″ Hammer Drill

- M12 FUEL 1/4” Hex Impact Driver

First things first…Why Did Milwaukee Develop the M12 Platform?

This is a GREAT story, and one that has had the folks at Milwaukee “Beating the drums” this past year with their M12 FUEL Gen 2 tools.

They developed their M12 line to meet two goals:

- They wanted to create a lightweight, compact tool that was optimized for the applications that MOST professionals do, most of the time. I’m talking about remodelers and MEP contractors that mostly drive 2-1/2 to 3″ deck screws and self-tapping screws.

- Hand tool replacement option. Milwaukee looked to M12 to solve repetitive motion activity movements that require a-lot of effort, and cause contractors repetitive injury

Using 12-Volts Fastening Tools

Let’s talk primary tools. There are many trades that simply do not need the heft of a larger 18-volt drill or driver as their day-in-day-out tool. For them, compact, lightweight and portability is more important.

Then there are guys, like me that really only need the 18 volt tool once in awhile, and prefer lighter tools to reduce fatigue. For me, it makes sense to own both platforms – and use them depending on the application at hand.

The truth is, Milwaukee M12 FUEL Generation 2 tools are the perfect balance for many contractors. When I think of contractors that can use 12 volt tools daily, I’m thinking of service contractors and punch list guys, cabinet installers, HVAC, Electricians, MRO and MEP contractors. To these guys, 12-volt tools offer a compact design, lighter weight and motor!

Just think – a tool powerful enough to handle the majority of your applications, and all of that power is in a compact enough package to fit easily on your tool belt!

Pros Use 12-Volt Tools

The assumption that 12-volt tools are for DIY-ers is so wrong. I’ve been using Milwaukee 12-volt tools in the shop, on service, and cabinet installs for years. Once you understand the unique and complimentary relationship of M12 and M18 you’ll see my point. It all comes down to choosing the correct tool for the application you’re doing.

If you need a tools for a powerful, more demanding application, like installing deck and framing ledger loks or lags then 18-volt tools are for you.

Seriously, if your work doesn’t require that, then why carry the weight? Would you lug a 55-gallon drum around all day just to get 64 ounces of water daily? No, of course not. Then why carry a larger higher capacity tool, if your work doesn’t demand it.

Whether you’re working inside a cabinet, confined space or overhead, you’ll appreciate the reduced weight and size.

Milwaukee’s goal is to build out their M12 line to cover all of the applications most MROs and MEPs would need. When you stop and look at the M12 breadth of line, its growing almost as fast as their M18 line.

What Does Milwaukee M12 Gen 2 Bring To The Table?

So what changes did Milwaukee bring to the table with their Gen 2 M12 FUEL drills and driver? These Gen 2 tools have brushless motors, and reduced size. In fact, the M12 tool size was reduced by 1-inch in length.

The M12 FUEL Drills changed in length only, same power. They also still have the 1/2″ all metal chuck, and is the only 12-volt tool on the market to have this feature. The 1/2″ check gives you the ability to run 7/16″ shank augers and hole saws. That’s huge! This tool delivers up to 1700 RPM’s and 350 in-lbs of peak torque. Weighing in at only 2.8lbs with battery and 6.6” in length, both tools are so nice to use.

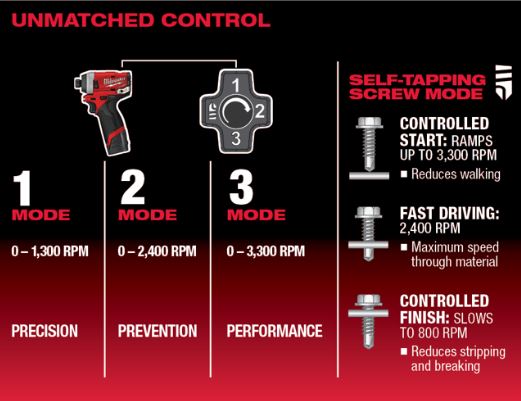

The M12 FUEL 1/4 in. Hex Impact Driver has an output of more than 1,300 in-lbs of torque. The Brushless Motor delivers 0-3,300 RPMs. The impact driver’s speed and torque were increased 25-30%, and Milwaukee added a 4-mode Driver Control to give the user more control of the tool.

A Self-Tapping Screw Mode was added, and is designed to reduce walking when starting self-tapping screws as well as reduce overdriving, breaking, and stripping out screws. This Self-tapping mode allows contractors working with sheet metal to work easier with self-tapping zip or Tek style fasteners.

The best part is that this tool weighs less than 2 lbs. and measuring only 5.1” in length.

Lastly, you’ll notice that the tools belt hook was slightly redesigned allowing it to clip more easily and hang with a better balance.

Self Taping Screw Mode

The secret sauce behind the M12 Impact drivers “Self-Tapping Screw Mode,” is in the electronics. The tools starts the screw slower to avoid fastener walking. It then senses when it penetrates the metal [by sensing a spike in current]and slows down the tools to avoid stripping the screw.

Runtime

(M12 FUEL ½” HDD):

- Application: ½” speed feed into 2×6 pine

- CP3.0 Battery: 137 holes

- XC6.0 Battery: 280 holes

(M12 FUEL ¼” Hex Impact Driver):

- Application: 3” deck screws into PT 4×4

- CP3.0 Battery: 193 screws

- XC6.0 Battery: 397 screws

Not the Biggest or Baddest

We can all agree that the M12 tools are not as powerful as their M18 bigger brother, but for MOST applications, it’s plenty powerful and comes in a lighter and more compact footprint. My point is that you don’t always need the Biggest, Baddest tool to do every job.

For more information on the Milwaukee 12 volt tools visit here.

About the author

5 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Simply the best tool reviews on the planet! very in-depth review on the tools and knowledge and skill of each tool reviewed! Great Job to Rob and his crew!

When does it get released

Great review. These are very good tools for their purpose. I’m glad Milwaukee updated them to be more compact. The control features are really well done. I have Bosch’s 18v dds183 drill driver and Maktia’s xdt14 impact and the drill has the same size head and the Mak impact is even more compact. Both 18v tools have more refined features but both are 18v tools and have slightly more weight and the 18v slide pack batteries are obviously more bulky. For all day and heavy extended use I prefer the more ergonomic handles of the 18v tools but these 12v tools have pro features that are useful for shorter use timeframes and for compact light weight professional use.

Excellent explanation for owning a 12 volt system. Very much appreciate this artice and your YouTube video. Both I have shared with others that expressed an interest in 12V tools. After reading this article and seeing your YouTube video I also added 12V tools, however being as I have many RIDGID tools I went with the RIDGID 12V.

I used a 12V for putting up a 60 foot fense. The weight difference between the 12V and 18V is 4+ lbs. When finished with the fense my arm, elbow, wrist and shoulder did not feel the strain as I do using the 18V. Now that I am in my mid 70s, very much I thank you for your 12V tools suggestion.

FYI, in your article you state “…unique and complimentary relationship…”, it should read “…complementary…”.

Again, this article is outstanding as are your YouTube videos,. They are very much a welcomed wealth of information.

Thank you.

Since you are correcting the author’s grammar, you should also correct your spelling of fence (not “fense”).