Best Safety Glasses Head To Head Testing

Choosing The Best Safety Glasses

I still remember the day the wind blew sawdust off a workbench and into my eyes – 4 hours later I was in an emergency room getting four splinters removed from my eyes, certainly didn’t SEE that coming! I’m pretty sure safety glasses would have prevented this mishap. So the question is, what should you be looking for in a pair of safety glasses? Are some pairs better than others?

Protecting Your Eyes

If you ask me that’s a simple answer, the best safety glasses are the ones that you’re going to wear! It seems that the “Most Common Excuse NOT to Wear Safety Glasses are:

- My glasses fog up

- They’re scratched to the point that it impairs my vision.

Safety Glasses Prevent Injury

According to the CDC, there are over 10,000 eye injuries in North America every day. Approximately 2000 of these injuries require medical treatment and 3 to 4 days off from work. Experts agree that using correct eye protection can lessen the severity or even prevent 90% of eye injuries.

NOTE – 63% of all eye injuries happen away from work. You might be cutting your grass, trimming weeds, performing DIY tasks on your property or while fishing. (google fishing eye injuries if you dare)

To decrease eye injuries, the American National Standards Institute (ANSI) and Military Combat Eye Protection Systems (MCEPS) created an intense impact and rigorous optical tests to determine the quality and effectiveness of safety glasses.

The eye is a delicate, irreplaceable and an essential organ. We need to protect it!

OSHA Requirements For Safety Glasses

General-purpose Personal Protective Equipment (PPE) requirements are addressed in Title 29 Code of Federal Regulations [CFR] 1910.132 of the Occupational Safety and Health Standards (OSHA).

OSHA basically requires employers to provide appropriate eye and face protection that complies with any of the these three standards

ANSI Eyewear Protective Standards [Hazard-Based, Final Rule]

On Sept. 9, 2009, OSHA issued a Final Rule concerning 29 CFR (Part 1910 and others) that revised the personal protective equipment requirements for eye and face protective devices, head protection, and foot protection. Employers must comply with this Final Rule by using and providing for employees eyewear that is constructed in accordance with any of the last three ANSI national consensus standards or their proven equivalent:

- ANSI/ISEA Z87.1 -2003

- ANSI/ISEA Z87.1 -2010

- ANSI/ISEA Z87.1 -2015

Military Ballistics Standard MCEPS GL-PD 10-12

To meet the need for a more aggressive standard than the ANSI/ISEA version, the Military Combat Eye Protection system [MCEP] standard was established. This standard contains a series of impact tests simulating intense ballistic velocities faced in combat.

Many safety glass companies offer MCEP rated safety glasses.

Safety Glasses Tested – Does ANSI Make a Difference?

The ToolBoxBuzz crew sampled a wide range of glasses that were easily available off the shelf at the big-box store or available online. We chose the $10-30 range in order to sample quality glasses. We also included one brand [HDX] that is sold in that price range as a 6-piece, bulk option. We chose HDX because it was priced low and MANY contractors buy these types of glasses in bulk.

Some of the glasses were “lens and frame” style and some were molded one-piece style. We tested the seven models, listed below:

- Bolle Prism II # 40059

- Edge Brazeau # XB131VS

- HDX #1004307679

- Honeywell UVEX # S2940XP

- Milwaukee # 48-73-2020

- Pyramex # SB8620DTM

- 3M # 47000H1

Safety Glasses Testing Criteria

There are many styles and features in safety glasses and as a result, the prices can run from a few dollars to $80 a pair. We decided to keep the samples in a reasonable price range. Using the $10-30 guidelines we chose safety glasses with the following criteria:

- Must comply with ANSI standard

- Must be within a $10-30 price range. [HDX excluded]

- No foam gasket attached.

Safety Glasses Testing

Most of the testing we conducted would be considered “High Impact” testing. We looked at seven categories, which included:

- Impact testing: Nail gun impact test, Steel spike impact test, and a Needle Penetration impact test

- Fog test

- Comfort

- Frame technology

- Visual clarity

- Thermal plastic rubber [TPR] technology

- Price

Impact Testing – What Constitutes An Impact Failure

The team decided that we would use four criteria to determine positive safety glasses’ failure. They were:

- Lens detachment

- Fracture of lens

- Penetration of rear of the lens

- Frame breakage

What happened next was amazing and “eye opening!” Yup I just said that!!

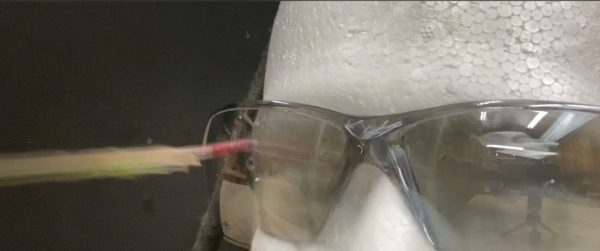

Photo: Moment of 16D nail impact. This is a dangerous test – Do NOT DO This!

Pneumatic Nail Impact Test

We shot four 16-penny [3-1/2″] framing nails from a distance of 12-inches. Each pair of glasses were affixed to a mannequin head and secured with a bungee cord.

What was truly amazing to the team was that ALL of the ANSI rated safety glasses, regardless of price-point, were able to withstand the nail strikes from such a close distance.

Photo: Pneumatic nail impacts on the lens

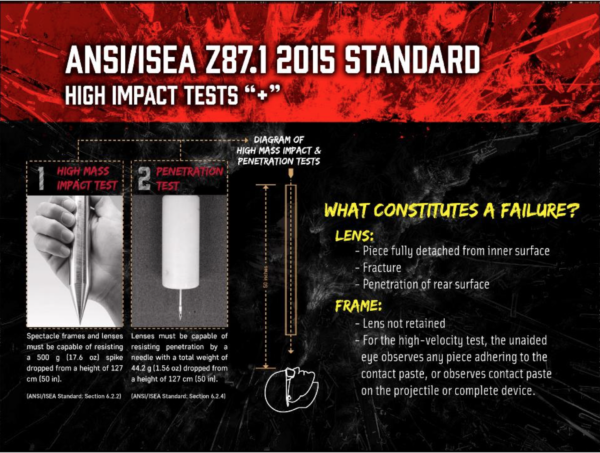

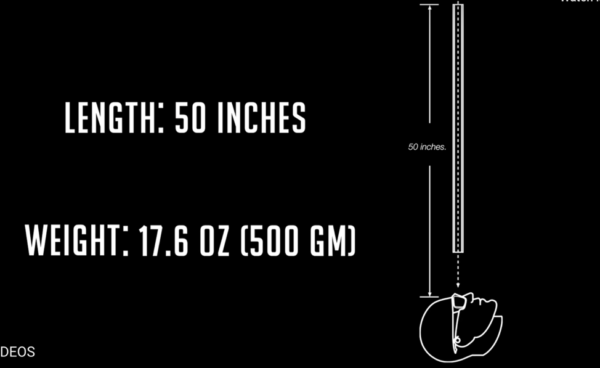

Steel Spike Impact Test [ANSI Standard]

Frames and lenses must be capable of resisting a 17.6 oz steel spike dropped from a height of 50″, measured from glasses to the top of pipe drop.

Pyramex was the only pair we tested that lost a lens during this testing. In the test, the opposite lens impacted by the steel spike “popped” out of the frame. The lens popped back in place.

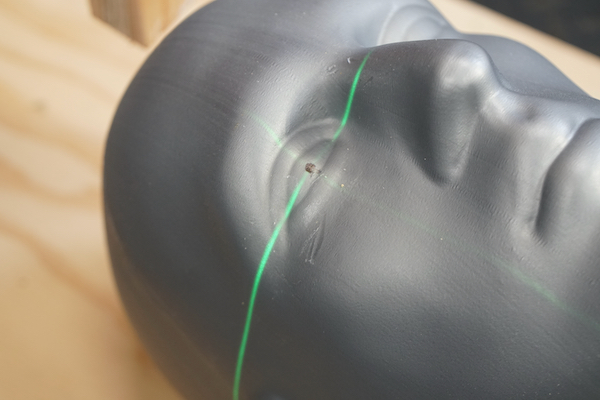

Needle Penetration Impact Test

The lens must be capable of resisting penetration by a needle with a total weight of 1.56 oz dropped from a height of 50 inches.

Photo: Moment of needle impact.

Impact Tests Tell It ALL – Ask for PROOF!

Safety glasses are much sturdier than regular eyeglasses and consist of a safety frame and safety lenses. Safety lenses are typically polycarbonate, which is unlikely to break. Under OSHA standards, safety glasses must be permanently marked with the manufacturer’s marking, followed by a “+” sign if the lenses are impact rated. Glasses that do not protect against impact will only include the manufacturer’s marking.

The marking appears in the upper or outer corner of the lens on prescription safety glasses

One important thing to note is that an ANSI rating does not require “3rd Party Testing,” however, a safety glass manufacturer MUST provide 3rd Party testing upon request. If you’re in charge or purchasing safety glasses for your company – make sure to request proof of third party impact testing.

Safety Glass Fog Test

One of the biggest complaints of construction safety glasses is fogging. Anti-fog coatings are designed to help reduce fogging in cold to warm temperature transitions (like from your belt to your face) in moderate to high humidity environments.

Atmospheric conditions, body heat and restricted ventilation with the eyeglasses can cause lenses to fog. We used a portable handheld steamer to accelerate fogging. This test was a Pass/Fail visual test.

Bolle and HDX failed this test. All of the other glasses have high-quality anti-fog lens coatings.

| Advertised Anti-Fog | Steamer Test | |

|---|---|---|

| Bolle- Prism II | No | Fail |

| Honeywell UVEX | Yes | Pass |

| EDGE - Brazeau | Yes | Pass |

| HDX | No | Fail |

| Milwaukee | Yes | Pass |

| Pyramex | Yes | Pass |

| 3M | No | Pass |

Two Types Of Anti-Fog Treatment

Not all safety glasses have anti-fog treatment and most of the ones that do have what’s called a hydrophobic coating. hyrdophilic coatings are a water-based coating, once you clean your glasses a few times, the coating is no longer effective. Top-quality safety glasses use hydrophilic anti-fog coatings and will last the life of the glass and is baked into the lens.

Hydrophobic [Good]

Most coatings in the North American market are hydrophobic. Hydrophobic anti-fog coatings are soap-based and work by repelling and spreading the fog moisture as it hits the lens. When the moisture spreads, it eliminates the fogging on the lens. While this is effective, the coating will wash off over time because of its soap-base.

Hydrophilic [Best]

Unlike hydrophobic coatings that repel water, hydrophilic coatings act like a sponge. Moisture droplets interact and absorb into the coating, eliminating fogging. Hydrophilic coatings are made with a proprietary polymer bond, that permanently adheres to the coating to the polycarbonate lens.

The coating is able to hold a high amount of moisture and naturally release the moisture at the edge of lenses, making them difficult to fog up. Because hydrophilic coatings are not soap-based, they won’t wash off as hydrophobic coatings will.

Comfort and Fit

Winner – Milwaukee

Safety glass temples should fit comfortably over the ears. To close gaps, make sure the frame is no further than a pencil with away from the face at any point. The nose should adequately support the bridge of the spectacle. the team evaluated each pair of glasses for comfort and fit. The Milwaukee glasses were the most comfortable followed by the EDGE and in third place a tie with Bolle and Honeywell.

Peripheral Vision

Winner – No clear winner

Safety glasses should protect the user from the reasonable probability of impact from flying objects, a protector with side protection has better protection

Assessing peripheral vision typically involves determining the field of view, which is usually measured horizontally from an individual’s nasal bridge outward. The field of you may also include a vertical measurement. There are a variety of methods for measuring the field of view, and the appropriate one may depend on workplace hazard assessment and/or job function.

The team felt that all of the safety glasses evaluated offered excellent peripheral vision.

Visual Clarity

Winner – EDGE

The team looked at the visual clarity of the lenses to determine any distortion of vision in different areas of the lens. The EDGE lenses were by far the best in this category followed by the Milwaukee in second place and Honeywell in third.

Safety Glasses – Features

There are not a whole lot of features for safety glasses.

TPR Technology

Winner – Milwaukee

Thermal plastic rubber [TPR] is a soft and pliable compound that increases its grip as it becomes warm or damp. This technology is used in temple tips and nose pads to prevent slipping and keep glasses on the face.

The team felt that Milwaukee had the best combination of TPR with Honeywell as second best and Pyramex third.

Frame Technology

Winner – EDGE

The team evaluated the frames and considered hinges, temple arms, peripheral coverage, and durable nylon compound construction. Edge easily took first place with Milwaukee in second, and Honeywell in third place.

Cost

Winner- HDX

While the HDX was considered a low price outlier, it did perform exceptionally well in our tests and cost approximately $3.50 a pair. Pyramex came in at approximately $5.00 a pair. Both the Edge and Milwaukee safety glasses topped the price list but as you can see in the subjective rankings scored tops in all those categories.

Honeywell’s UNEX glasses certainly deserve the BEST VALUE in this testing. Coming in at approximately $10 a pair these glasses scored top tier in almost every category and cot half of the most expensive safety glasses.

| NAME | MODEL | ANSI | COST (ea.) |

|---|---|---|---|

| Bolle- Prism II | 40059 | Z87.1+ | $8.77 |

| Honeywell UVEX | S2940XP | Z87+ | $10.30 |

| EDGE - Brazeau | XB131VS | Z87.1+ | $28.25 |

| HDX | 1004 307 679 | Z87.1+ | $3.67 |

| Milwaukee | 48-73-2020 | Z87.1+ | $21.97 |

| Pyramex | SB8620DTM | Z871 + High Impact | $5.30 |

| 3M | 471000H1 | Z87.1+ | $12.37 |

Best Safety Glasses – Specialized Lenses

Some manufacturers offer specialized lenses in different shades and coatings for different lighting conditions or tasks. For example, EDGE Eyewear offers a wide variety of shades with different light transmission properties to improve clarity and contrast and UV protection. They also offer welding lenses with additional UVC protection for metal workers and fabricators. These lenses may seem like overkill to some but they can make a tremendous difference in how well you can see your work.

Polarization

Reduces glare and reflection dramatically, improve contrast, difficult to use with some electronics as the screens are sometimes polarized and the two polarized surfaces can cancel each other out making screens look black.

Reflective coatings

Reduce glare, improve contrast

Colored lenses

Different colors help improve contrast and clarity under different lighting conditions.

- Yellow, amber, rose, and red-tinted lenses help improve contrast in situations with a lot of blue light, early morning, dusk, snowy or cloudy conditions.

- Blue tinted lenses, light blue lenses can normalize incandescent or sodium vapor lighting. Blue mirror lenses help reduce glare.

- Neutral lenses, provide true-to-life color rendition while reducing overall light transmission.

What Safety Lens Is Right For You?

Personal preference and the lighting situation are the two major factors. If you want all-around dark tinted safety glasses a neutral would probably be the way to go. If you’re working outside or in environments that have UV light then UVA, UVB, or UVC protection would be a good way to go. Variable lighting such as partly cloudy days or moving from interior to exterior environments can be easier with a mid-range tinted lens in copper or amber color. Do your research and try a couple of options. One way to keep from spending a ton of money is to get glasses that have interchangeable lenses.

Best Safety Eyeglasses | Overall Winner

Winner – Milwaukee

Milwaukee took first place followed closely by Honeywell and Edge in close third place. All three of these glasses have anti-fog technology. Both Milwaukee, Honeywell, and Edge impressed the team in almost every category evaluated.

All of these safety glasses impressed us with impact testing, especially the nail gun test. With that said any of these glasses will protect you from flying objects. Now that we got that out of the way let me remind you of the two biggest reasons why we don’t like safety glasses:

- They fog up

- They scratch and obscure my vision

Fogging should NEVER be a problem for you if you chose the correct safety glasses. All three of the top-ranking glasses have permanent bonded anti-fog technology applied to the lens as opposed to a wash/wear off coating after extended use or repeated cleanings.

Now anti-scratch technology is a bit different and there is no standard technique to test for this, and manufacturers don’t test for it so it’s harder to evaluate it.

| Comfort | Frame Tech | Visual Clarity | TPR | Impact Test | Price | Final Rank | |

|---|---|---|---|---|---|---|---|

| Milwaukee | 1 | 2 | 2 | 1 | 1 | 6 | 1 |

| Honeywell UVEX | 3 | 3 | 3 | 2 | 1 | 4 | 2 |

| EDGE - Brazeau | 2 | 1 | 1 | 5 | 1 | 7 | 3 |

| HDX | 6 | 5 | 5 | 6 | 1 | 1 | 4 |

| Pyramex Ever- Lite | 5 | 4 | 4 | 3 | 7 | 2 | 5 |

| Bolle- Prism II | 3 | 6 | 7 | 7 | 1 | 3 | 6 |

| 3M | 7 | 7 | 6 | 4 | 1 | 5 | 7 |

Final Thoughts – Best Safety Glasses

The moral of the story here is that any ANSI impact-rated safety glass will protect your eyes from debris and projectile impact. But if you want to wear them for any length of time, during physical activity, then get a pair with hydrophilic anti-fog technology. Keeping them in a protective case, when not wearing them, so they don’t scratch is a must. Once they scratch bad enough you won’t wear them – right?

Stay Safe!

Best Safety Glasses Testing Video Review

About the author

8 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

I’m 100% safety glasses. That is the only way to insure that you have them when you need them. Most construction workers ack like PPE is a unnecessary burden.

Not wearing safety glasses is foolish.

Then again if you have ever done any government work, they take safety to the point that it is dangerous!

Fantastic research, guys! I wear safety glasses most of the day and have wondered whether the Z87.1 rating actually means much. Apparently it does. This gives me a bit more confidence in the glasses, though the nail gun test still makes me cringe. This is a very informative article. I’ve had a few near misses that made me really glad the glasses were on. Perhaps someday you might devise a test to measure sawdust entry around the perimeter? Windblown sawdust is the worst.

Great summary – thanks. I would add another important reason that people don’t wear safety glasses: they can’t see without “help”. The is particularly common as we approach ‘aged to perfection’ and it’s amplified by the fact that we didn’t make PPE a habit “back then” because our mentors didn’t. (We _have_ to be better mentors.)

So, we tend to wear our prescription (drugstore or otherwise) glasses so that we can actually see what we are doing. And they (typically) do not offer appropriate wrap-around protection and some don’t have adequate impact protection.

Many of us we can see and focus well with a simple diopter correction (e.g. drugstore glasses.) Tuns out that it is easy to get real safety glasses with simple corrections for not much more than the cost of decent safety glasses reviewed here (and in fact) from some of the same manufacturers. You can order them from industrial supply houses (e.g. Grainger) and on-line from the classic tool places and from Amazon among others and you can (sometimes) find them “on the shelf” at hardware store and DIY places.

If you need better ‘help’ get find good safety glasses and get you optometrist to grind your prescription!

For folks who work overhead, you can get glasses them with corrections in the top and the bottom (the normal place.)

A couple of examples – there are many others.

3M has a large selection:

https://www.3m.com/3M/en_US/company-us/all-3m-products/~/3M-Readers-Safety-Eyewear-2-5/?N=5002385+3294427617&preselect=3293786499&rt=rud

Uline:

https://www.uline.com/Product/Detail/S-10493C-2.5/Safety-Glasses/Jackson-Safety-Safety-Readers-Clear-25-Strength?model=S-10493C-2.5&RootChecked=yes

Hello. This post was extremely interesting, particularly because I was looking for thoughts on this topic last Thursday.

I am a nurse in the Operating room and I purchased NoCry glasses for eye protection. They arrived quickly and are exactly what I was looking for.

When choosing the ideal safety glasses for work, the lens material is a determining factor. Currently, the most used materials for protective eyewear are organic, Polycarbonate, and mineral lenses.

Great article! Thanks so much for sharing!

good