Milwaukee Dust Extraction Soultions

Milwaukee Dust Extraction Solutions

Tick, tick, tick. That’s the sound of the time marching on towards June 23rd, the date when enforcement of the new OSHA silica exposure rule was supposed to go into effect. Until last week a lot of us contractors have been scrambling to get all of our concrete tools updated with dust extraction interfaces. Things will be switching soon from a PPE (personal protective equipment) solution to an engineering control based solution. This means that when cutting, drilling or grinding concrete, the dust is collected or controlled at the source instead of relying on a respirator at the last possible moment before breathing it.

It was a welcome relief when many companies, including our own, learned that OSHA had pushed back the enforcement date 90 days. It gives all of us a little more time to get our ducks in a row to make sure our employees are protected instead of rushing into it and hope we have it figured out.

Maybe Milwaukee needed a little extra time too to make sure they get it right. At the 11th hour they’ve announced an expansion of dust extraction solutions. While they’ve had the HammerVacs for awhile, the new shrouds, chisel boots, and HEPA vacuum are new.

What Does It Mean

So what does this mean? As an end user if you buy a Milwaukee rotary hammer or grinder, you can be confident that there is a dust extraction solution to make that tool comply with the silica rule. These solutions also work with many older Milwaukee grinders and rotary hammers. These solutions work with many competitor’s tools as well.

There is a “but” though, two of Milwaukee’s biggest grinders have too much surface area and OSHA requires >175 CFM for these tools. As of this writing, none of the major tool brands have a HEPA vac capable of that volume.

8 Gallon Dust Extractor

The cornerstone of Milwaukee’s dust extraction solutions is their new 8 gallon HEPA vac. This unit is auto filter cleaning, meets OSHA compliance, has power tool actuation (corded tools only), and 148 CFM. The hose end of the unit of course hooks up to all of the shrouds and boots in the lineup.

Improvements

I think the introductions are a great first step and will ensure just about anyone that they are in compliance with the new OSHA silica rule. If I’m being honest though there are a couple things I’d like to see improved in the 2nd generation. First, get a little more CFM out of the HEPA vac so that the big grinders can be in compliance too. Lastly, I’d like to see Milwaukee develop a hollow bit like Hilti’s or Bosch’s. We use the Hilti ones all the time on the job site and they clean the hole perfectly so we don’t have to blow them out before injecting epoxy.

Press Release

Milwaukee® Dust Extraction: A Solution for Every Concrete Cut, Grind, or Prep

04/12/2017

MILWAUKEE, WI- Since first introducing the world’s only universal self-powered dust extractor in 2013, the M12™ HAMMERVAC™ Universal Dust Extractor, Milwaukee Tool has been dedicated to introducing productivity-focused dust collection solutions. Now, Milwaukee Tool is excited to announce the largest expansion of its Dust Extraction System to-date, all completely compliant with the new Occupational Safety and Health Administration (OSHA) regulation on respirable crystalline silica dust.* With the launch of an 8-Gallon Dust Extractor and accessories, the company’s full lineup of rotary hammers and grinders are compliant through either Table 1 or Objective Data Requirements.**

The heart of the system, an 8-Gallon Dust Extractor, features an automatic filter cleaning mechanism to allow for sustained airflow at 148 CFM in dust-producing applications. The Extractor’s dual filtration system (complete with HEPA filter) captures 99.97% of all particles greater than 0.3 microns. For SDS Max hammers, there is a new dust extraction attachment for drilling holes up to 2-3/4” in diameter and a chisel boot for chipping applications. Also available will be new cutting dust shrouds that work with the Extractor to maximize dust collection during concrete cutting with grinders.

These new accessories will join Milwaukee’s current lineup of HAMMERVAC™ dedicated and universal dust extractors – the most complete system of cordless, battery-powered dust extraction solutions in the industry.

Milwaukee Tool provides a full range of corded and cordless grinders for all concrete applications. The company also offers a complete lineup of rotary hammer solutions optimized to meet the full range of user needs in each distinct SDS Plus rotary hammer market segment, as well as the most demanding applications in the large SDS Max segment. Compatible with more than 125+ power tool products, these solutions will be supported in full by Milwaukee’s Dust Extraction System.

Milwaukee® is committed to improving productivity by providing performance-driven and trade-focused solutions so users can perform an entire day’s work. As the new OSHA® regulation continues to create the framework for a safer jobsite, Milwaukee Tool is dedicated to continuing to expand its Dust Extraction System, including the addition of new Vacuum Bits this Fall.

* According to OSHA, over two million construction workers a year are exposed to crystalline silica dust. Found in materials like concrete, tile, rock, stone and brick, exposure to silica dust can be a major cause of a fatal lung cancer known as silicosis. The new OSHA regulation on respirable crystalline silica dust (29 CFR 1926.1153) will be enforced for construction trades starting on September 23, 2017. This regulation reduces the Permissible Exposure Limit (PEL) to 50 µg/m3 over an 8-hour period and will affect jobsite nationwide.

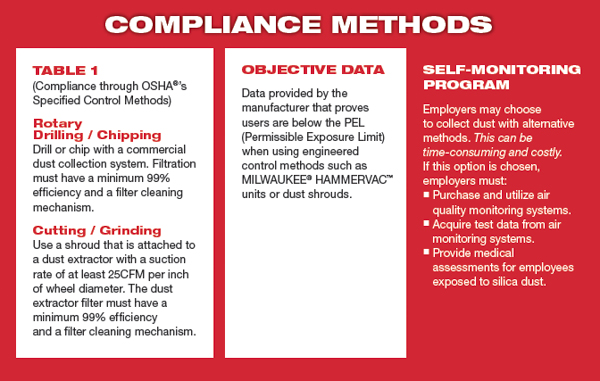

** In order to be compliant with the new regulation* companies prove they are under the PEL by following Table 1 standards, demonstrating objective data, or conducting their own self-monitoring programs, as laid out by OSHA. [See attached document for how each of our tools comply].

- HammerVac works with just about anyone’s rotary hammer

About the author

1 Comment

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

When is the dust extractor coming out?