Milwaukee 2155-AC Temporary LED Site Light

Milwaukee 2155-AC RADIUS Temporary LED Light Review

In the commercial construction world, temporary site lighting is an interesting trade-off between functionality, convenience, energy consumption and cost. We were very interested to see how Milwaukee 2155-AC Temporary LED Light would perform on our project site. We installed four Milwaukee 2155-AC Temporary LED Lights at Local 537 Pipefitters Training Facility.

The 2155 light is a very high quality LED device. The light was shipped with an attached AC cord and, in our case, we needed to use a romex cable system that was installed between rooms so the AC cord was the first modification we made to the light.

Easy to Wire

For the attached cord, Milwaukee built the stress relief into the side of the Milwaukee 2155-AC Temporary LED Light case and it holds the cord quite effectively. The stress relief works with romex and armored bx cable. We undid the stress relief by loosening two captured screws. The factory installed cord was free to remove after unscrewing the terminated hot, neutral and ground wires from the terminal blocks.

Next, we installed the romex wiring harness on each 2155-AC light fixture. I measured the time for the electrician to wire and hang the light in the ceiling by its built in wire rope. It took less than three minutes per fixture. The installation of the four 2155 fixtures on the construction floor took less than 15 minutes in total.

Milwaukee really thought through the wiring issues as the wires have a built-in chase in which to fold and the screw terminals are very heavy duty and easy to use. While our romex installation was not daisy-chained from fixture to fixture, the 2155 makes this easy to accomplish if needed with a back-to-back terminal block system.

2155-AC Terminal Block

The installation of the fixture in the ceiling is simple with the use of Milwaukee’s integrated wire rope and snap-in connector fittings.

Rugged Mounting

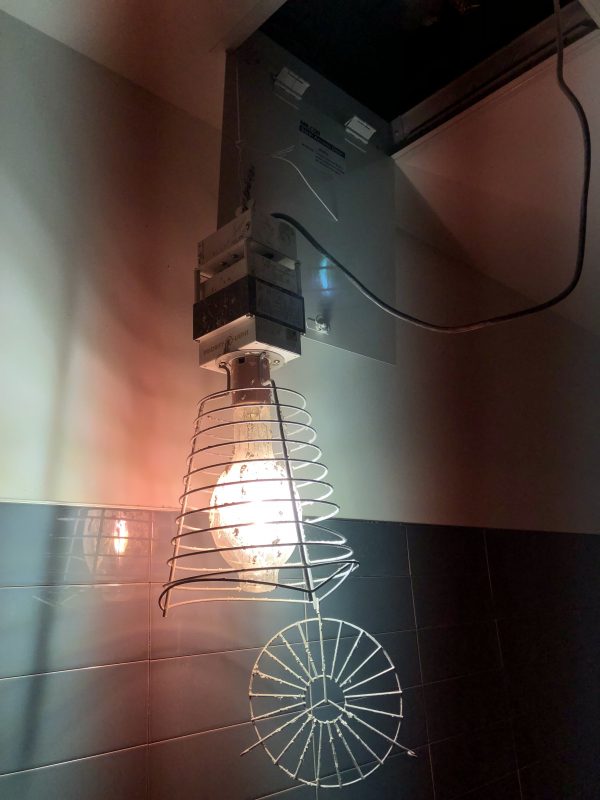

The Milwaukee 2155-AC Temporary LED Light is a substantial and more rugged mounting system than I am used to seeing on a construction site. I know the 2155 can take much more wear and tear and stay in place than ordinary temporary lighting installations. For example, I show two different mountings that were installed in rooms next to each other on the site.

2155-AC in place using its wire rope.

Typical Temp Lighting Support

When careless lift operators run into either of these installations, I know which one will need to have bulbs replaced and rehung by the electrician.

Cost Effective

One of the aspects of temporary site lighting is the cost. We often use the cheap plastic enclosed incandescent lights as seen tin the previous picture. Clearly, these types of cheap strings will be less expensive to purchase than a high quality Milwaukee 2155-AC Temporary LED Light fixture. But the 2155 is substantially brighter and will require fewer lights in an open construction floor area. Also, the 2155 will use less electricity than an incandescent bulb and in this environment of more sustainable approaches to construction, the LED temporary lighting is becoming a green requirement over incandescent bulbs. In a facility like the Pipe-fitters in the high-bay areas, the electrical contractor used a system of high intensity high bay fixtures such as the one, below.

In this case, the relative cost difference in the initial high bay fixture costs is minimal, if not in favor of the Milwaukee 2155. Change one high bay bulb due to abuse of environmental exposure and the scale is definitely in favor of the Milwaukee fixture. As you can see, the environment in a construction site can be brutal on lighting. The electrical contractor relamped this fixture ($30+ Bulb Cost) after the spray fireproof-er killed the bulb.

Metal Halide High Bay Fixture – This One Out Of Service Due to Spray Fireproofing

Operating Cost

In today’s construction environment, contractors are concerned with green engineering, carbon footprints and sustainability. The 2155-AC LED light puts out a whopping 7700 lumens of light with 70 watts of power. The metal halide bulbs, alone, consume 400 watts of power. Add in the electrical consumption for the transformers and the 2155-AC saves even more power. When faced with environmental conscious project requirements, contractors can claim credit for reduced temporary lighting power consumption.

High Quality Bright Light

I also liked the light output of the Milwaukee 2155-AC Temporary LED Light . In a room with two incandescent temp lights, I measured the illumination level right below one of the lamps at 25.7 lux. In the adjacent room with one 2155 fixture, I measured the light intensity at 623 lux. Clearly, the intensity of the 2155 is far superior.

Milwaukee 2155-AC Temporary LED Light Features

- Easy setup

- No maintenance

- 7,000 lumens

- Reduces energy by 30%

- Wire up once, accepts 120-277V

- Power Consumption: 70 W

- Color Temp: 3900

- Spring-loaded cable retention (accepts 14/2 Romex to 10/3 MC)

- TRUEVIEW Technology

- Available: December 2017

- Milwaukee supports the cost considerations with a web-based cost calculator. Go to https://www.milwaukeetool.com/

Temp-Lighting-Cost-Calculator

In summary, the Light the Site experiment I made with the Milwaukee 2155-AC Temporary LED Light fixtures was an overwhelming success. We installed the 2155-AC fixtures in a less than 3 minutes per fixture. The installation is safer and the mounting more robust. The light quality is superior. In comparison to metal halide installations, the 2155 -AC will save money over the life of the project.

Milwaukee can light my sites! #LightTheSite

Milwaukee 2155-AC Temporary LED Site Light Video Review

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.