HILTI Concrete Sensors

HILTI Concrete Sensors Review

My company is the Construction Manager that is currently constructing four major buildings for large-scale development in Cambridge, MA. My project is a 20 story 468 unit residential project. Recently, HILTI approached me to see if I were interested in reviewing the HILTI Concrete Sensors on my project. The timing of their request could not have been better. We just reached the bottom of our three-story underground parking garage, and we were beginning to pour pile caps and foundation elements.

I have an active interest in construction technology. I also knew that we had some excellent technical reasons to pursue a monitoring system on a trial basis.

We met with the HILTI representatives and agreed to review their concrete monitoring offerings.

Reasons for Monitoring Concrete

Let me outline five concerns that GC/CMs often have: when dealing with concrete

- Concrete is poured into the forms, and, at specified intervals, samples are taken to break in a laboratory at a later date to determine the concrete strength. However, the concrete cylinders almost immediately go into an insulated storage box, are transported to a lab, stored indoors, and do not see the same conditions as the concrete that went into the ground. The in-situ environment can make a dramatic difference in the concrete performance.

- How soon is the recently poured concrete strong enough to subject to loading?

- The concrete temperature, especially in a mass concrete pour, can vary between the center of the pour and the concrete’s external faces. When does the contractor need to put on a layer of concrete blankets to keep the temperature differential within tolerances?

- Moisture mitigation can be a large budget item in a commercial project. The need to employ different moisture mitigation fixes depends entirely on the concrete floor slab’s relative humidity. Often, the flooring contractors measure the relative humidity in the concrete slab. It would be a better system if the GC/CM could proactively monitor the drying trend from the beginning and also not rely upon the flooring subcontractor for the only RH readings.

- When and how will I know when concrete conditions warrant remedial work?

The quick answer to all of these concerns is, “There’s a HILTI App for that.”

HILTI Concrete Sensors Solution for Concrete Monitoring

In March of 2020, HILTI acquired a Boston-based company that created a concrete monitoring solution with real-time reporting. In addition to the hardware and software necessary to instrument the concrete, the HILTI solution has its internal testing laboratory that tests mix designs with the actual local ingredients to produce the correct curing profiles for each different mix design per ASTM C1074 Maturity Method.

These two parts of the HILTI solution – the field sensor technology and the laboratory analysis – collaborate to create a comprehensive solution. The HILTI sensor application allows the user to know the real-time status of the instrumented concrete.

The move to acquire Concrete Sensors makes sense, as the HILTI brand and their tools and existing technical product lines are targeted for commercial construction and, specifically, the concrete industry. HILTI already has hi-tech products for asset tracking, engineering, BIM, and tracking fasteners. Concrete sensors is another technical innovation product line for HILTI.

HILTI Concrete Sensors Diagram

HILTI Concrete Sensors Setup – It is Quick and Easy

For our trial demonstration, the HILTI representatives showed up at the site with everything needed to monitor our first concrete pour. We were about to pour a large braced-frame mat foundation in less than an hour when HILTI arrived with their equipment.

The braced frame mat was 6′ thick, 15′ wide, and 103′ long. The concrete volume was 343 cu. yd. We instrumented the mat in three locations with a sensor at the center of the pour and the surface.

For hardware, HILTI brought six concrete sensors (3 for monitoring the center of the pour with extended leads and three for monitoring the surface), a Gateway, and a handful of zip-ties. We plugged the Gateway into power, downloaded the mobile App (available in iOS and Android), and then initialized the sensors.

Initializing the sensors was a straightforward process:

- Remove the physical sensor from the packaging.

- Expose the sensors to light to “wake them up.”

- Scan the sensor into the HILTI CS mobile app

- Zip-tie the sensors onto hook-shaped rebar to allow the deep sensor to reach the middle of the mat

- Install the sensors in the brace frame.

- Pour the concrete and start collecting data.

There are a few things in the installation picture above to note. First, the center sensor has two pieces with the transmitter portion installed close to the surface and the instrumentation located 3 ft below. Second, the surface sensor has the instrumentation and the transmitter combined into one unit installed close to the surface. Finally, the concrete subcontractor installed their thermocouple temperature sensor onto the piece of epoxy costed rebar with the tangle of yellow wires.

The braced frame pour was sufficiently large enough to be designated a ‘mass-concrete’ pour. We needed to ensure that the center and outside of the pour did not exceed a 45 deg F differential for an extended duration. This temperature differential requirement drove us to the HILTI Concrete Sensor solution.

Main Reasons to Monitor Concrete

With an advanced system like HILTI offers, concrete sensors give project personnel instantaneous data on the absolute temperatures, the relative temperature in paired sensors, relative humidity, and strength of the concrete on-site, without waiting for lab results back. The process should also yield more accurate results, as well, because the sensors are measuring the actual in-situ conditions. In contrast, the laboratory cylinders will never see the same conditions as the poured concrete and can be subject to human error.

Often in commercial construction, the engineer of record will specify a comprehensive thermal control plan that describes the temperature monitoring procedure that the general contractor or concrete sub-contractor must implement when placing concrete. The specifications detail the requirements for cold or hot weather conditions and that for mass concrete pours. These specifications often include a variety of details:

- Minimum and maximum allowable temperature values for different locations

- The maximum allowable temperature differential for mass concrete placements

- The type of equipment, sensors, and tools for temperature measurement

- The frequency and duration of temperature readings

- The use of additives in concrete depending upon the extreme temperatures for the pour event

Also, many engineers allow the in-situ concrete temperature measurements to estimate concrete strength using the maturity method (as per ASTM C1074) in real-time. This allows the contractor to obtain the field strength of the concrete in real-time. The maturity method enables the contractor to optimize the results to allow for stripping forms, removal of support of excavation bracing, pulling post-tensioned cables, allowing work to proceed on the concrete slab, and other activities that depend on the concrete strength. In summary, this allows the contractor to avoid delays in waiting for concrete testing cylinders to dictate the site activities.

Also, the monitoring of concrete temperature and strength allows the contractor to optimize heating and cooling costs. Contractors can have heat blankets installed or removed to keep temperature differentials within tolerances.

How Did the HILTI Concrete Sensors System Perform?

The HILTI rep explained the following events would happen with the pouring of the slab:

- Temperature data collection would start as soon as the sensors are covered in concrete

- Relative Humidity data collection would start as soon as the sensors are covered in concrete

- Reporting and alerts are available in the app as soon as data is downloaded from the sensors (long-range/gateway=automatic, bluetooth=someone needs to walk within range and connect to each sensor)

- Strength reporting/alerts would be enabled by the 24-hours worth of temperature data

True to their word, we started to see reporting data on our iPhones the next morning after the pour.

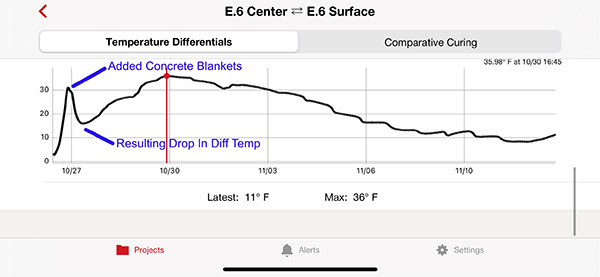

Interestingly, we observed that the temperature differential was rising between the center of the mass pour and the surface of the concrete. We were concerned that we might exceed the maximum differential limit given the temperature differential curve’s trajectory. As a result, we ordered the concrete subcontractor to place heat blankets on the brace frame concrete’s surface. Within an hour, we could see the blanket placement results as the surface temperature rose, bringing the temperature differential down. That was a real-time example of an immediate benefit of the system.

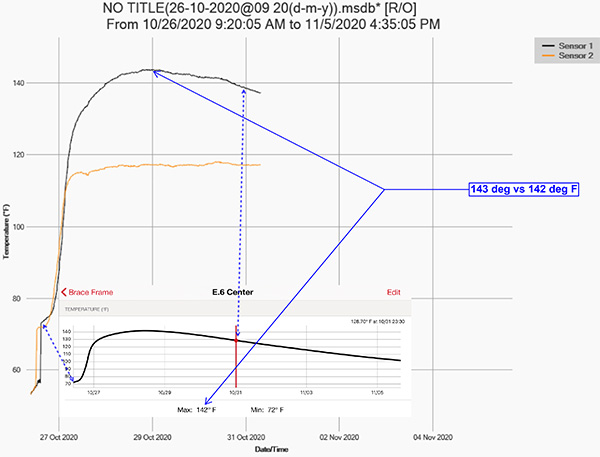

I pointed out that the concrete subcontractor had a thermocouple in the HILTI sensor’s vicinity in the middle of the braced frame. When we received their data output, I compared it to the HILTI data stream from the same location. While the data scales are different, you can see that the two sensors produced identical curves. Also, they had a maximum temperature reading that differed by only one degree. That was independent verification of the accuracy of the HILTI monitoring system. I have included the two temperature curves below:

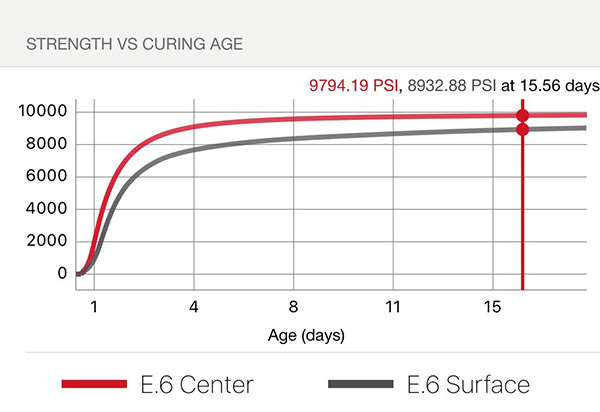

We could also observe the strength of the mat concrete in the data stream, below:

The surface concrete reached a strength of 7,500 psi on the second day and we allowed work to take place on the surface, knowing the strength to be sufficient.

What are Other Monitoring Systems Available?

The good news is that contractors have many ways to monitor concrete available. Each of the options has its tradeoffs based on cost, accuracy, reporting capabilities, ruggedness, automation capabilities, and ease of use. Contractors need to consider all of these factors when making an informed system selection.

I conducted a brief look at what is available on the market. I sorted what I found into four categories, below:

- Thermocouples

- Wired Temperature and Data Loggers

- Wired Concrete Sensors with External Wireless Transmitters

- Fully Embedded Wireless Concrete Sensors (HILTI SYSTEM)

I have ranked this list from the most straightforward approach, thermocouples, to the most sophisticated system. Each of these approaches has its advantages and disadvantages. Contractors need to conduct a detailed review before selecting a concrete monitoring program that meets the job requirements.

I do not suggest that my look at the concrete sensor market is exhaustive or inclusive. My analysis provided enough information that I am comfortable classifying the product offerings I encountered.

A Look Back on the HILTI System

As I said earlier, HILTI’s timing was perfect because we were at the start of our concrete cycle. In addition, our concrete mixes were already in the HILTI library, which consists or 170+ local mix designs from around the US and Canada.

Fortunately, our mix design was in the HILTI inventory. If that had not been the case, we would have needed about a four week lead time to have their laboratory test and categorize the mix performance. HILTI could then certify strength calculations. Most users will need a month to have their mix designs tested. And, of course, users must account for those costs in any cost analysis.

We determined that we had more than enough upcoming needs for concrete monitoring in our internal discussions that we elected to rent the HILTI Gateway and purchase additional sensors for our first concrete slab pour. We wanted the strength calculations to validate the date we could start removing the support-of-earth braces to start foundation wall construction. (Fortunately, the slab mix design was also in the HILTI inventory.) We purchased the sensors, and we poured the slab a few days ago. We already see the strength of the concrete on our iPhones.

Finally, we will use the HILTI sensors on our elevated slabs to monitor the concrete strength, monitor the concrete temperatures, as we will be pouring these slabs during the winter. We will also have the temperature data to enable the spray-on fireproofing to be installed at an appropriate temperature. Also, we will use the relative humidity readings to know the exact moisture content. That data allows us to match the correct adhesives to the actual slab Rh and to avoid expensive moisture mitigation processes.

Summary

I would be remiss to omit how well the HILTI personnel supported our effort. I certainly recognize that any company would help such a product review to ensure a positive outcome. However, I have no reason to believe that any customer would not have a similar positive experience. Their product presentation and initial product setup were excellent. These folks know their business inside and out and guide prospective and existing customers through the system with no issues.

I also observed a seamless relationship between the HILTI Concrete Sensors solutions team and the other HILTI personnel. They both demonstrated a customer-centric and dedicated approach to their business. The combined group has a real commitment to this technology and this business.

In summary, I am very impressed with the hardware, software, and people making up this HILTI business. HILTI has a real winner with its concrete sensor business and I look forward to using their system on my projects.

About the author

2 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Very cool, Stan. How deep in the concrete can these sensors go?

One of the sensors has a separate data collection portion and communication portion. I believe it was outfitted with an 8′ long cable. But for really deep pours, HILTI can make a longer cable connection. We used this configuration in our first experience and it was a 6′ thick mat concrete pour.