Ryobi 12.5″ Thickness Planer Review

Ryobi 12.5″ 15Amp/120V Benchtop Thickness Planer (Model AP1305)

Ryobi 12.5" Thickness Planer (Model AP1305)

Specifications and Features

Specifications:

- Depth control: 1/20 inch increments

- Total Knives: 2x 12.5″ straight blades, steel

- Motor: 120V / 15 amp

- RPMs: 18,800 Max

- Frame: 4-column steel frame

- Table Size: approx. 31″ combined infeed and outfeed tables

- Includes: (1) AP1305 12-1/2″ Thickness Planer, (2) Planer Knives, Knife Removal Tool, Hex Key, Dust Hood, and Operator’s Manual

Features:

- 2-inch removable dust collection port fits standard shop vacs

- Lever-operated turret depth stop allows users to easily set frequently used thicknesses

- Front-panel integrated cutter height/cut depth gauge

- Fold-up infeed and outfeed tables for compact storage footprint

- 3-year manufacturer’s warranty

Overall Power & Performance

Power and performance in a planer are all about consistent blade speed and feed rate plus table size and angle. To establish the Ryobi AP1305’s ability to perform consistently I planed several different boards. While hardwood is the typical benchmark of power, I have found that other applications can be as much or more challenging to a perfect finished surface.

Boards Tested

- Standard 2×4 Fir stud, 8 ft

- 8” wide Hard Maple, 6 ft

- 6” wide Soft, Weathered Pine (dry)

- 6” wide Soft, Weathered Pine (Moist)

I used a similar set-up to previous thickness planer tests I performed in my shop. Here’s why this serves as a good baseline:

This range of boards allowed me to test for finish due to challenges associated with hardness, width, length, and moisture content. Hardness, especially over length, can cause the motor to slowdown or overheat, leading to an increase in cross-board tear out and/or chipping. Maple in particular, due to having grain swirls throughout is prone to chipping where planning “against the grain” on a swirl is unavoidable. Short or very long boards can increase the chances of board snipe and cause issues with feed roller performance. Wood with high moisture content is prone to fuzzy grain syndrome and can cause ripples in some instances. Lastly, narrow boards are susceptible to poor seating which can lead to ripples if the board rocks or shifts at all during planning.

Performance Takeaways

So what’s the bottom line? The AP1305 was a consistent performer but with some common challenges. The 15Amp motor performed decently but because Ryobi paired it with a 2-knife cutterhead, it bogged down slightly on the longer lengths of hard maple. A 2 vs 3 knife cutter head mean the motor must maintain a higher constant RPM to account for the increased rotation of the head between knife cuts (Standard 3 Knife 15 Amp planers @ 10,000 RPM vs AP1305 @ 18,800) if the head diameter is equal between both. A good measure of final performance is cuts / inch since this ratio captures the relationship between motor rotation rate, cutterhead size, and knife count.

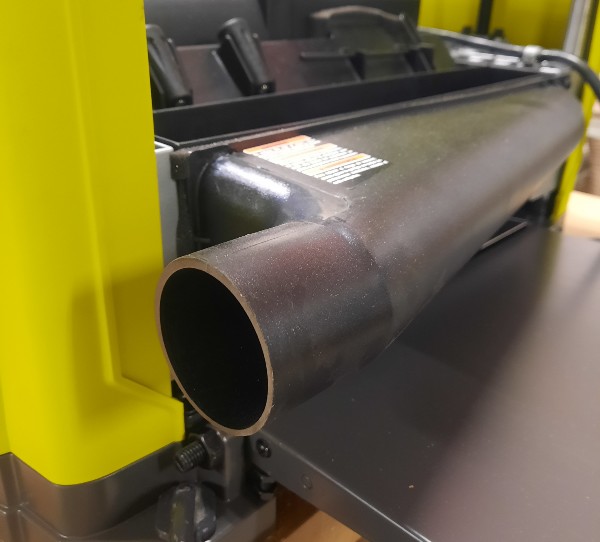

Cutterhead without protective cover

Measurements & Gauges

There is a single measurement gauge on the Ryobi AP1305 and it is easy to read and use. It shows the total cutterhead height and subsequent total final planed thickness of the board being planed. The best way to calibrate this gauge is to 1) set the gauge to a starting thickness 2) plane the board 3) Accurately measure the actual board thickness (I used Vernier calipers) and 4) loosen the 2 Phillips head screws on the red gauge needle and set it to match the measured thickness.

One gauge that’s common to most planers, but not found on the Ryobi AP1305 is a removal gauge. Typically this gauge is located in the middle part of the feed guide. It roughly compared the board thickess to the cutterhead height and indicates about how much material is going to be removed. This is a great feature because it helps ensure you don’t remove too much material on a single pass and damage the planer. Ryobi absolutely needs to consider adding this basic feature to future versions of the Ryobi AP1305 planer.

Example Removal Gauge (Not Ryobi AP1305):

Dust / Chip Collection

The one thing I was most concerned about with this small planner was dust and chip collection. The overall dust/chip collection was slightly below average compared to other 12.5″ thickness planers for one primary reason; dust port size. Many competitor planers feature a standard 4-inch port (with a 2 inch adapter included) so you can hook up a dust collector. The Ryobi AP1305 comes standard with a 2 inch port which hooks up to a standard shop vac. The standard performance difference between a dust collector and shop vac is significant. And while the shop vac worked ok, it was a case of once you go big you can never go back. And I was left wanting to hook up my dust collector…

Integrated Safety Features

The AP1305 planer features a basic paddle-design slap-off safety switch. Its’ a simple but effective switch common (for good reason) on many shop tools meant to maximize no-look shutoffs. This switch also has a standard removable “key” insert that prevents the tool from being started when removed. This is a basic safety option for accidental start-up related injury prevention.

The other common injury cause by thickness planers is lacerations during blade changes. The blades are extremely sharp (yes, even when considered “dull” for wood) and don’t offer much safe gripping surface when removing the blade. Ryobi included 2 features to address these concerns 1) 2x magnetic blade grippers and 2) an integrated cutterhead lock to securely hide the blade edge during blade changes. Both are appreciated and work great. And also not standard on many other competitor models. The magnets had no issues lifting and securely holding the blade when tested.

Final Thoughts | Ryobi AP1305 Planer

I am a big proponent of matching tools to requirements. If you are not a professional carpenter or cabinetmaker then you don’t likely need a professional grade planer. Ryobi has done a decent job of matching the AP1305 planer strengths to the basic needs of their target audience; the hobbyist and weekend DIYer. The Ryobi AP1305 planer can quite effectively plane a variety of woods while requiring no expertise to set-up or operate. It is also comparatively cost effective at $329. If, however, you are looking for a tool to use frequently or for a project with longer lengths of hardwood, I would consider looking at a more robust planer.

Ryobi should consider 3 low-cost upgrades to future versions of the AP1305. First, they should add a material removal gauge for reasons previously discussed. Second, they should consider adding height adjustment measurements onto the crank handle. This would help users have a rough idea of the equivalency of a half turn in material removed for example. Lastly, Ryobi needs to update their website to reflect the correct handbook for the AP1305. They currently have the AP1300 manual from 2002 loaded on the AP1305’s page.

Ryobi Ryobi 12.5" Thickness Planer (Model AP1305)

About the author

7 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Thank you for your time and experience it helped me to solidify my decision to have my daughter get one of these as she is pursuing a hobby trying to make a living up at Minot North Dakota even though I am from Worcesester

God bless

Thanks for the thorough review. So helpful! May I ask a question here?

I have many 8’x2x4’s warped from being left outside. Is a this planer appropriate to take bends out?

Bob

A planer will not fix that. A planer is a “thickness planer”….it will take a uniform amount off the piece….you’d need a jointer. Even then…it might not work that well as the board is flexible and you would likely flex it as you cut the high spots.

you can mill the bends out using a simple jig. You can google it. Pretty much, you need a flat surface for the board to rest on. Shim and secure your work piece so it doesn’t flex. Send both the jig and the work piece through the planer. Very simple but effective.

This is very helpful.

Thank you

Thank you Ben, Very helpful! Superb photos – well written and presented ❖

Thanks for the info. I’m looking for a cheap planer to do small hardwood projects such as jewelery boxes and things of that nature . I can’t justify an 8or900 dollar piece of equipment for this, At least not at this stage of the game.