Oliver Machinery 12.5″ Planer with SHELIX cutterhead Model 10044 Review

Oliver Machinery 10044 Planer Review

Oliver Machinery 12.5″ Planer Model 10044

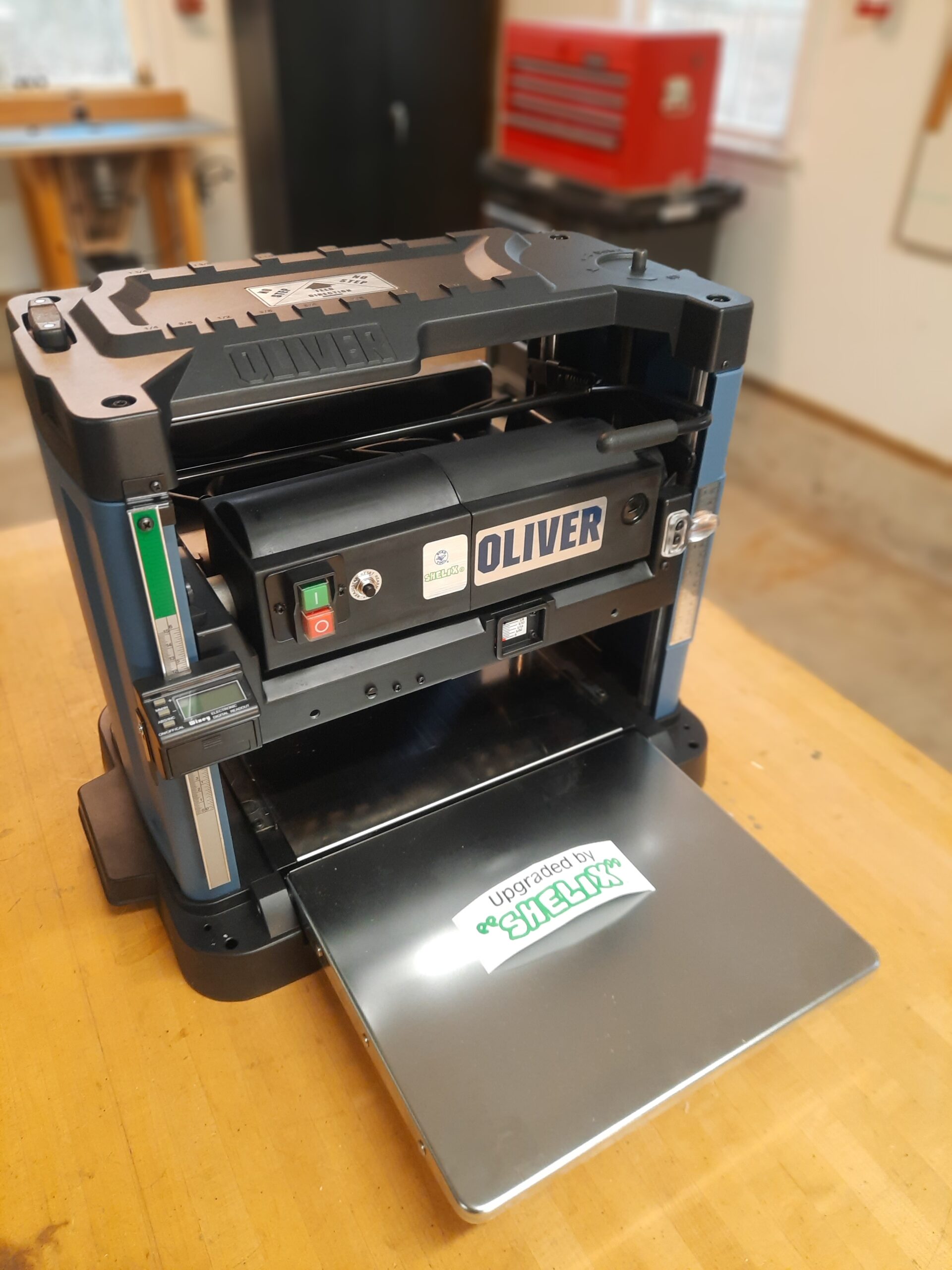

When I decided to upgrade my 12.5” planer, I wanted to check out the Oliver Machinery 12.5″ Planer (Model 10044) with exclusive Byrd Tools SHELIX cutterhead. The thickness planer is one of the most functional and cost-effective tools in my woodshop. Why? Because it ensures uniformity in materials and allows me to effortlessly repurpose or resize an otherwise mismatched pile of lumber. See our previous Planer head-to-head article for a rundown on top non-helical choices!

Oliver Machinery may be a new name in the high-end home woodshop market for some, but they’ve been setting the standard in the USA since 1890; their accolades started with the introduction of the round cutterhead (and a gold medal) in the 1900 Worlds Fair in Paris! And if you haven’t heard of them, it’s probably due to their heavy involvement in the large-shop industrial sector for the last few decades. Recently they’ve refocused on the commercial and high-end home workshop. Below are some of the key spec’s on this tool.

Specifications and Features – Oliver Machinery Model 10044

Specifications:

- Motor: 2HP, 120V, 1Ph, 15A

- No Load Speed: 20,000 (motor) / 10,000 (cutterhead) RPMs

- Max Depth of Cut: 5/64”

- Depth Capacity: 6″

- Width Capacity: 12.5″

- Tool Weight: 68 lbs

Features:

- Exclusive Byrd Tools SHELIX Cutterhead tuned and ready out of the box

- Powerful 15 AMP, 2HP motor handles larger cuts in wider materials with ease

- Integrated digital Wixey gauge allows user to dial-in height to the nearest 0.0025”

- Fan-assisted chip ejection blows chips off of the cutter-head for efficient chip removal

- Pronounced magnetic power switch allows for ‘quick-stop’ and anti-circuit-restart safety features

- Material removal gauge and extra-large thickness scale deliver accurate cuts

- Lever-operated turret depth stop allows users to easily set frequently used thicknesses

- Includes T20 Torx driver and bit, T25 Torx wrench, 10x extra carbide knives for long-lasting cutting, and a 2.5” dust hose adapter

Simple Setup / Ease of Use

The Oliver Machinery Model 10044, 12.5” Thickness planer was a breeze to set-up. It is a sexy looking planer as well; I was impressed with the balance of integrated measurement options and streamlined design. Out of the box, the unit is average weight when compared to similar 12.5” planers (@ 68 lbs). The initial set-up couldn’t have been easier; I attached the crank handle and dust collector shroud, put some batteries in the digital readout, plugged it in and it was ready to go.

I’m also a proponent of reading through the manual before using a tool, just as a matter of habit. Oliver Machinery included a note stating “We test the finished product before shipping to you. If your planer has a few wood chips in it, it’s from us…” Truth be told, I was as excited to check out the SHELIX cutter head as to see the finished surface. I had the cover off in no time and can verify that there was indeed wood dust inside the assembly from the factory. Of note, the tuning done at the factory was spot on but more on that in a bit…

To start, use the top cover guides to get a rough starting thickness of the board. Then you lower the cutting head to about 1/16” lower than that height. Next, slide the board under the material removal gauge to verify that the cutter head height is set to remove the desired amount. Last lock the cutter head in place, turn on the machine and dust collector and slowly feed the board in until the infeed roller takes over. That’s it. Continue the process until you reach the desired height. I also questioned whether the plastic top cover would allow the posts in the 4-post design to flex when the cutterhead locking handle was locked. But I saw no flexing at all. I am also curious if the plastic top cover will be prone to wear/cracking if boards are in working contact with it over time.

Pre-Cutting Inspection

The pre-cutting inspection and set-up were impressively easy. And I’ve been running a top-of-the-line competitor’s 12.5” thickness planer for years. There was no blade alignment comparison to make sure the edge of each blade were perfectly parallel. The factory tuning combined with the Spiral Helix cutter head design made for a seamless first cut. The cutter head is raised and lowered via a top-mounted, smooth-turning crank handle. Each full rotation of the handle raises or lowers the cutter head by 1/16″. This is nice because it allows you to easily thin the material to the ballpark of the overall thickness without constantly measuring. This is a standard feature on many thickness planers. Another standard feature of many thickness planers is the finesse required to dial in the final 1/32” to match an existing piece’s thickness. However, this is not a standard feature of the 10044.

Oliver Machinery made the 10044 planer easy to maintain as well. Another feature I appreciated is the easy ability to change the carbon motor brushes when they reach end-of-life. Oliver Machinery says the brushes should last approx. 170 hrs. All that is needed to swap them out is to remove the front and back located button caps and remove/insert the carbon brushes. I’ve used plenty of other tools that required you to take apart the motor housing for a brush swap so I greatly appreciated this small design consideration.

Easy To Use & Read Gauges

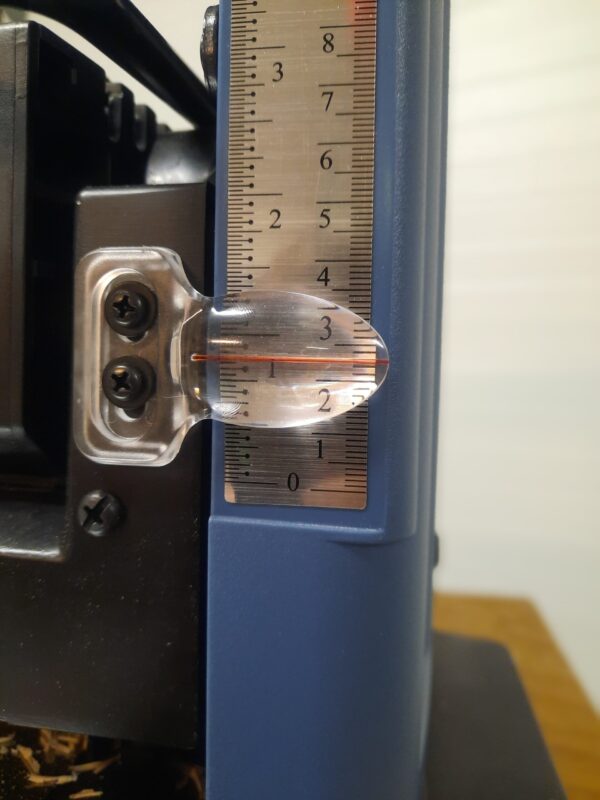

Digital Wixey Gauge

The Oliver Machinery 10044 includes a digital Wixey gauge to allow users to easily and precisely dial into a desired thickness. Here’s how it works. First, plane a board so you have uniform thickness throughout the width of the board. Then measure the thickness of the planed board (I used a digital Vernier caliper). Next, turn on the gauge and hold the “CAL” (calibrate) button for a few seconds. Once it’s blinking use the + button to make the thickness match your measured thickness and you’re done. The Wixey gauge is accurate to 0.05mm or 0.0025 increments.

I set the gauge, raised the cutter head a couple of inches, lowered it enough to cut approx. 1/16” off a board and then compared the accuracy of the Wixey gauge to my digital vernier caliper. As you can see in the picture below, the Wixey gauge was 0.0015” off the vernier caliper, well within the stated 0.0025” tolerance. I then adjusted the handle to make them as close as the display would allow and it was approx. 1/12 of a handle crank. I couldn’t ask for better results than that. The Wixey gauge can display in SAE or Metric and has an additional “increment” option (INC) which allows you to see the digital readout for how much you lower or raise the cutter head vs. the overall height (ABS).

The only drawback I could find with the Wixey gauge is that the is a very slight amount of play where the gauge attaches to the vertical support measurement bar. I only noticed because when calibrating the sensor and pressing the up button I saw the reading change 0.005” when I stopped putting pressure on the + button. I applied pressure to either side of the gauge and the measurement changes slightly. This change equates to about 1/12 of a handle rotation which seemed close to equivalent to the play in the tension chain on my high-end competitor’s 12.5” thickness planer.

Other Gauges on the Oliver Machinery 10044 Planer

There are three other gauges on the 10044 and they are both easy to read and use. The first is the removal gauge shown above shows how much height will be taken for that single pass. It ranges from 0 – 1/8” in 1/64” increments. The thickness gauge was spot on straight out of the box.

The next gauge is the overall cutter head height gauge. This is essentially just a visual reminder of how thick the piece is. It also allows for easy adjustment by loosening 2 screws and raising or lowering the red line indicator. One added feature is the magnified looking glass style sight. This makes it easy to dial in the overall height adjustment to the 1/32” increment.

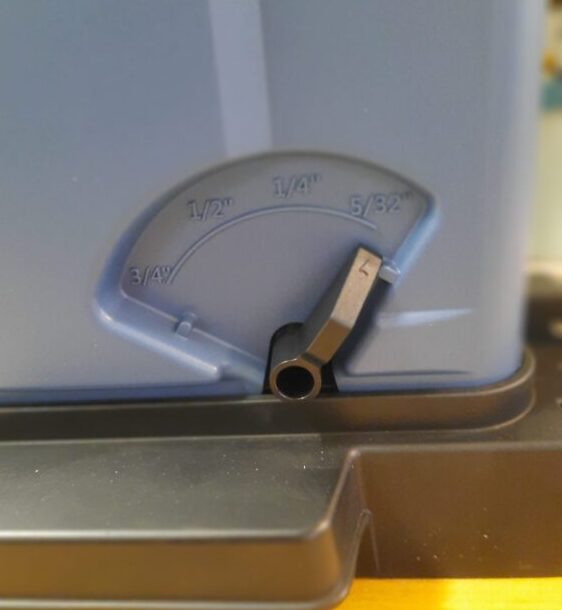

Lastly, there is a lever-based Turret Stop, used for repetitive planing of multiple pieces at standard thicknesses. It’s located on the lower right side of the unit. The Turret Stop has 4 pre-set thicknesses of 5/32″, 1/4″, 1/2″, and 3/4″. This is a great feature when trying to plane lots of boards to the same final thickness. You simply raise the head above the desired level, turn the lever to the desired height setting, and lower the cutter head until you feel resistance against the depth stop.

Power & Performance

Power is tough to describe and, to me, best illustrated through consistent performance. The Oliver Machinery 10044 Planer is a consistent performer. To establish the 10044’s ability to perform consistently I planed several different boards. While hardwood is the typical benchmark of power, I have found that other applications can be as much or more challenging to a perfect finished surface.

Boards Tested

- 2” wide Hard Maple, 3 ft

- 4” wide Hard Maple, 2 ft

- 8” wide Hard Maple, 6 ft

- 6” wide Soft, Weathered Pine (dry)

- 6” wide Soft, Weathered Pine (Moist)

This range of boards allowed me to test for finish due to challenges associated with hardness, width, length, and moisture content. Hardness, especially over length, can cause the motor to slowdown or overheat, leading to an increase in cross-board tear out and/or chipping. Maple in particular, due to having grain swirls throughout is prone to chipping where planning “against the grain” on a swirl is unavoidable. Short or very long boards can increase the chances of board snipe and cause issues with feed roller performance. Wood with high moisture content is prone to fuzzy grain syndrome and can cause ripples in some instances. Lastly, the narrow maple (especially a shorter length) is susceptible to poor seating which can lead to ripples if the board rocks or shifts at all during planning.

For a great in-depth explanation of common issues associate with planning see this Woodworking Network article. So what’s the bottom line? Regardless of the board type, size, or storage conditions, the 10044-produced cut surface was consistently excellent. The competitors straight blade planer’s finish had multiple visible cross-grain abrasions and tears (see photos below).

Oliver Machinery 10044 Planer finish – with graphite dust for contrast

High-end competitor 12.5” 2-blade finish – with graphite dust for contrast

Dust / Chip Collection

The one thing I was most concerned about with this small planner was dust and chip collection. I’ve got a pretty robust dust collection system in my shop, however the amount of dust and chips that a planer produces gave me reason for concern. The Oliver Machinery 10044 has a built-in chip blower mounted at the rear of the unit. It helps push chips out from the unit and into the dust collection pipe. This combined with the dust collector creates a system that works exceptionally well.

The dust port is located at the rear of the unit above the outfeed opening of the planer. It is a standard 4” port that exits to the left of the machine. The height combined with the side exit means that the hose is out of the way from obstructing exiting boards. The dust and chip collection is exceptional on the 10044, not only because of the fan but also because the smaller helical carbide blades produce smaller wood chips. The smaller chips equal easier collection and high-quality dust removal. Each time I’ve used the DW735 I’ve been able to capture all of the chips and dust. Planing is one of the tasks in the woodshop that creates the most volume of chips and dust. Because of the built-in blower fan, this planer can easily capture all the dust regardless of cut depth and board width.

In the picture above I planed 20 ft of 6” (10 BF) poplar boards and only used my 1.5HP, 600CFM dust collection system to control dust. I haven’t blown off, swept off, or moved the system. The overall dust collection was very good, even when compared to the same dust collection set-up hooked-up to my 2-bladed, 12/5” competitor planer.

Byrd Tools SHELIX Cutter Head

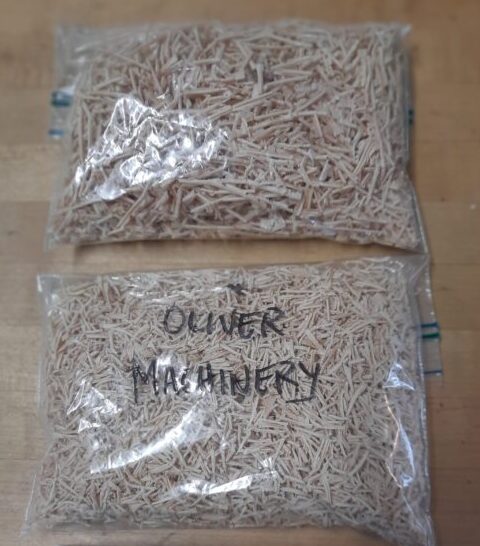

The SHELIX cutter head contains 3 rows of 9 spiraling, carbide knives. Each carbide knife is 4 sided so if it is nicked it can easily be rotated with the provided torque driver/bit. This means approx. 20x more efficiency in blade replacement. It also means much lower replacement costs as a single ($1.05/cutting edge vs avg. $5/cutting edge).

Equally important, it means significant time savings due to the elimination of the need to align the blades on installation. One Torx driver is used to remove the top planer cover and dust cover. Changing the blades only takes about 2 minutes (as opposed to about 15 mins for a standard 12.5” 2-sided knife) with the provided Torx driver and bit. In the image below you can see the 3x spiraling rows of 9 blades with the center located T20 torque screw on each blade. To top it off, Oliver Machinery supplies you with an extra 3 blades or 12 cutting surfaces. You can also purchase additional sets of 10 carbide blades directly from Oliver Machinery ($58) or Byrd tools.

Advantages of SHELIX cutter head vs. standard planer cutter head

- Extreme noise reduction

- Chip outs are virtually eliminated

- Optimization of dust collection system (smaller chips)

- Necessary replacements of knives cost a fraction in most cases

- Knives are made from carbide; last 40x longer

- Simple & alignment-free knife changing

Of note, some planers will advertise a helical-style cutterhead where 4-5 knives are placed over the length of the cutter head in 6 separate rows. While these helical-style cutter heads offer some of the advantages of the Byrd SHELIX cutter head, they are NOT an equivalent product. They are aligned in straight rows and offer only 2 cutting surfaces per blade. This means they will not have the same overall noise reduction, chip out reduction, dust collection optimization, or cost savings when compared with a true SHELIX cutter head. This is a point easily glossed over in advertising and a fundamental driving factor of Oliver Machinery 10044 Planer’s value and performance. Below is a comparison picture of the Oliver Machinery 10044 Planer wood chips vs. a high-end competitor’s 2 straight blade wood chips.

Integrated Safety Features

One of the most important aspects of a top-notch design is safety features. I look for 2 main features in all of the tools I own; 1) an ability to shut the tool off immediately in case of emergency and 2) an option to control the electricity to a tool (lock-out/tag-out is no joke for a small commercial shop). The magnetic switch included in the 10044 meets both these requirements. It’s a quick slap-off design with a protruding off button design. I would prefer a paddle switch over the off button to maximize no-look shutoffs but it’s functional as is. The Oliver Machinery 10044 Planer also uses a magnetic switch that must be manually restarted in case of power shut off at the breaker for any reason.

The other safety feature I enjoy is the low-mounted carrying handles. Strain from carrying heavy equipment (even if infrequently moved) is a common injury. The carrying handles are top-mounted on many other planers,. The handles are bottom-mounted on Oliver Machineries 10044 however. This allowed me to brace the equipment against my chest for more stability when carrying. It also eliminated the equipment hitting my legs when walking which was a much-appreciated bonus.

Overall Performance & Pricing

Oliver Machinery makes a lot of great industrial tools and their high-end shop line is easily on par with them. With the exclusive pairing of the Byrd Tools SHELIX cutterhead and the Wixey digital gauge, this is a game-changer. Another note I felt compelled to include is the high-quality manual that Oliver Machinery includes. It may not seem like a big deal, but detailed color photos for each step, diagrams of inside components, incredibly detailed specs, and ample customer service contacts are not always standard in tool manuals. Kudos to the technical writing team at Oliver Machinery for their attention to detail.

At $849.99 (MSRP), the model 10044 planer is a bit more expensive than other 12.5” thickness planers. But when you calculate the cost of another planer with a comparable set-up (12.5”, 2HP motor, 4-post design), like the DEWALT DW734 (MSRP $449, Lowes.com), and add the cost of a Byrd Tools SHELIX upgrade ($535, Byrdtools.com), you end up with a total price of $985. That’s $135 saved. If you compare the model 10044 to the Jet “helical style” 722130 planer ($799, OhioPowerTools.com) this is still a great deal. Does this mean that everyone needs to spend the extra money for the 10044? Probably not if you only fire up your planer a few times a year. But tools are an investment… and by the numbers, this is a great investment without many direct comparisons.

Final Thoughts – Oliver Machinery 12.5″ Planer

I planed a wide variety of woods from soft pine to hard maple, stored in a variety of conditions, over my last few projects. Each time I’ve planed the material the finish is so smooth it hardly even needs to be sanded. The ease in setting up and planing pieces of wood is incredibly impressive. The finish from the SHELIX cutterhead is an industry benchmark for a reason. Combine all that with a very well built product, a team with a dedication to their products, and a 2-year limited warranty, and you have a winner.

My recommendations for Oliver Machinery to improve upon the 10044 planer are to 1) add a paddle switch for emergency shut offs, 2) replace the heavy-duty molded top cover with a formed metal top cover and 3) add cord wrap brackets for cord storage when not in use. In my opinion, this is a perfect planer for small and medium-size woodshops. This planer needs to be at the top of your list if you are in the market for a small-shop planer.

Oliver Machinery Oliver Machinery 12.5″ Planer Model 10044

About the author

25 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

A very helpful, thorough review. Thanks, Ben!

Daniel, no problem. Appreciate the feedback and glad you found the review helpful.

I just purchased the Oliver 10044. I too was bugged about the cheap plastic top. So, I started looking at and measured the holes in the metal top of my old DeWalt 734. Seemed like it would fit? It did!! To a tee! Had to remove the turret lever, can still adjust it with a philips head screwdriver. That’s likely a feature I’ll never use anyway. Hopefully Oliver will offer a metal top for this machine in the near future.

Hi! I have been looking at planers and was thinking of the Dewalt 735x and wondered how this compares.

Luke, Great questions and a tough one too. Both Planers have definite advantages. They both sport equal 15Amp motors, fan-assisted chip extractors, 4″ dust ports, and removal and thickness gauges. The DEWALT gives you an extra half-inch of width, 2 feed speed options, and a larger fixed (19 3/4″) base, and is $100 cheaper. The Oliver gives you a SHELIX cutter head and a digital Wixey gauge. So I guess the answer is it depends. If you are sold on a true helical cutter head then I think the Oliver is the way to go. You could add a SHELIX head to the DW735 but it will cost you about $350 more total. And I’m not sure on DEWALT’s warranty or the implication of swapping out the cutter head. The finish of the Oliver is excellent and I love the no-adjustment required and low maintenance costs of the SHELIX head. I think it is worth the extra $100 and appreciate knowing it doesn’t void the warranty in any way. That’s not a knock on DEWALT. I ran a DW734 for years as my planer of choice but have never owned a DW735; but DEWALT also make a great product. And the larger base and auto carriage lock work great for snipe-free planing. Also check out:

https://www.toolboxbuzz.com/head-to-head/best-benchtop-thickness-planers-head-to-head/

https://byrdtoolexperts.com/product-category/dewalt-planers-and-jointers

Hope this helps and thanks for reading! Ben

I didn’t see any mention of where this planer is manufactured.

Allan, It’s manufactured in Taiwan. Thanks for reading!

I purchased this planer based on this review. I’ve fed it some pine scrap to get the feel of it. Then I put it to work removing 22 years of weathering from 5 5 1/2″ wide, 8′ long reclaimed red mahogany.

It works as described. The machine produces a good finish and very fine dust that disappears into my HF dust collector.

I’m very happy with this purchase. Thanks for an informative and factual review

Matthew,

Glad to know the review was helpful with your purchase decision. Thanks for the feedback! We definitely pride ourselves on honest and factual reviews at TBB. Happy planing! Ben

So many planers are identical so like a lot of people I figure one company is knocking the out.. My question is on the chain drive for cutter head and if they are plastic or metal..?

Brian,

They are a Poly-V belt design in line with many mid to higher-end, belt-driven planers (and table saws). Thanks for the great question and reading the article! Ben

When will this planer be available for purchase again?

not sure

Great review. Your education and experience makes for a very complete and informative review. Kudos!

George, thanks for the kind comment. Glad you found the review to be helpful! Thanks for reading. Ben

Great review. Thanks

1. do you use the carriage lock when using? Is it really needed? Maybe on final cut?

2. I have a decision to make with today’s cost.

Oliver $1000

DeWalt 735x is $570 plus $500 SHELIX cutters. = $1070

Not much different in cost. Any thoughts.

Thank you Eric

Eric,

1. Yes, I use the carriage lock. could you get away with not using it? I suppose. but for accuracy and cutting consistency it matters. the spiral groove posts and consistent upward pressure during feeding/cutting, plus the vibration of the cutter head when spinning means that the vibrations will invariably cause the cutter head to slightly move upward when cutting without it. I mean, for the 1 second it takes to lock it, I don’t see a practical reason not to.

2. I would probably go with the Oliver strictly because modifying any tools runs the risk of increased breakage and voiding of a warranty. its’s a close call for me though. Because the DW735 has some distinct advantages. Namely it has a larger base and infeed tables as well as a 2-speed gearbox. Those are features the Oliver doesn’t have so I guess in the end its a personal decision. The other feature that directly relates to your first question is that the DW735 sports an auto-carriage lock feature.

Hope this helps and thanks for reading!

I have the opportunity to get one of these brand new in box for $600, what are your thoughts on this planer having used it for some time? I’ll be running mostly 10″x20″ eastern white pine through it

Hey Tom,

Thanks for the question. I have been extremely pleased with my Oliver Machinery 12.5″ planer. I have used it for hours and hundreds of board feet of hard, soft, and even a little pitchy wood. It has consistently delivered over the past year plus. I think Oliver Machinery has a winner on its hands. The cutting performance of the SHELIX head has been consistent and excellent. And the blade rotation process is a snap. I would have no reservations about adding some Oliver blue to your shop in the form of this Planer if you’re going to be thinning up some white pine. Just remember the max width of the boards accepted is 12.5″, so anything wider than that is a no go! Good luck, and thanks for reading!

Ben

I have a Dewalt 735 with the automatic lock. On the Oliver, do you have to unlock and lock the cutter head each time you adjust the cutting height?

Rob, Your hunch is correct. The Oliver 10044 does not have an automatic locking head. It, like the DEWALT 734, has a manually locking lever that must be released and locked each time you raise or lower the cutter head. Thanks for reading! -Ben

Great review. After having the planer for over a year, have you found any issues with consistency of performance? Interested in your long term thoughts now that you’ve had it for a while.

Steve,

Your timing is great. I’ll be publishing a 1.5 year review in a couple weeks. Bottom line is that my Oliver 10044 planer has consistently performed quite impressively. The SHELIX cutterhead has been awesome and I haven’t noted any major issues. I have planed hundred of Board Feet of both soft and hard woods. Overall, it’s been a solid piece of equipment in the shop. Thanks for reading! -Ben

I bought a new DeWalt and it sits in the corner. My $20 Ryobi garage sale planer does a better job. I’m liking this Oliver though.

Ben,

Thank you for the detailed review! I always search for reviews when considering a purchase and I have never seen such a thoughtful and thorough review. I will search for your review update, but I am now definitely leaning toward Oliver.

Kerry