Oliver Machinery Table Saw Model 10010 Review

Oliver Machinery 10″ Table Saw w/ Roller Stand Review (model 10010)

Oliver Machinery Table Saw Model 10010

Oliver Machinery 10010 Table Saw Specifications & Features

The Oliver Machinery 10-inch table saw (model 10010) is an excellent job site table saw. It offers features found on the best job site table saws out there. The overall build quality is on par with the best manufactures. The balance of power, design features, ease of use, versatility, and overall quality make this saw an easy top choice for any PRO in the construction field.

- 2 in 1 Machine. Blade or sanding disc included

- Rack & Pinion Telescoping Fence System

- Lighted overload indicator panel

- Variable speed motor with constant torque over RPM range

- Magnetic switch for power interruption protection

- Rip fence features L-shaped flip-down attachment for thin stock

- On-board tool and accessory storage

- Arbor lock for quick blade change

- Quick-mount riving knife & anti-kickback paws

- 2-1/2” port works w/most shop vacs

- Adjustable rear material support

- Fold-up, rolling stand

Power & Performance | 10010 table saw

Motor Design

The Oliver Machinery model 10010, 10″ job site table saw features a powerful 15 amp/2HP motor with a no-load speed of 2,000 – 4,200 RPM. The blade speed isn’t the highest in the industry but proved more than enough for anything we threw at it. We used it for cutting common job site materials to include: 3/4″ plywood, 2×4 & 2×6 framing material, and 1×3 Curly Maple. The motor is also variable-speed and constant-torque. This is an awesome feature and something few competitors can boast! It’s pretty easy to adjust for whatever task you want to tackle with the front-mounted dial.

Cut & Sanding Options

The 10010 comes with both a 10″ blade and 10″ sanding disc to support dual-mode use. The adjustable torque is especially useful for sanding or cutting hardwoods that you don’t want to be marred with blade scorch. While a sanding disc isn’t something that we would use every day, it’s a great feature for the times you do need it, like touching up an almost perfect crown molding miter. Switching between cutting and sanding is quick and easy since the sanding disc is mounted on the arbor in the same way as the 10″ saw blade. The set-up took us less than 2 minutes. The 10010 can also be loaded with a stacked dado blade and Oliver Machinery offers a dado blade insert for sale for $39.

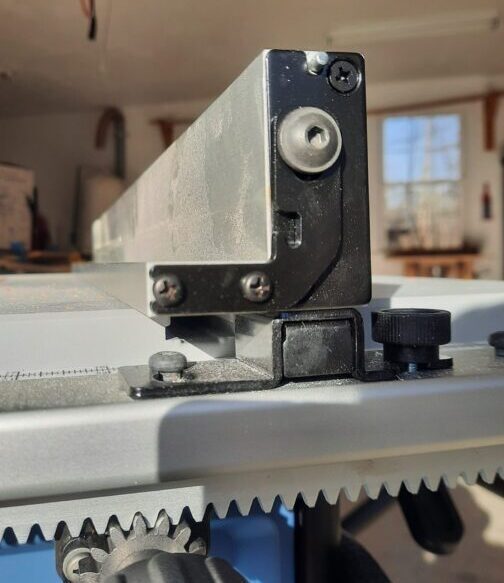

Rack and Pinion Fence System

The Oliver Machinery 10010 table saw’s rack and pinion fence system ensures that the fence is always perfectly parallel to the blade. It has highly-accurate adjustability and is a very sturdy design. The fence has a near and far attachment point on the rail carriage. The rail mounts to the carriage’s protruding bolts and relies on a thumbscrew to secure it in place. This allows for an extra 4″ of total ripping capacity, bring the max rip to 28″ total (right of blade). The adjustment knob is then used to dial in the exact fence position required. DEWALT has been using a rack and pinion fence design for years and it’s a tried-and-true design we’ve always loved at Tool Box Buzz!

The fence also has a flip-down, thin-stock guide included. This feature provides two useful benefits. First, when ripping narrow pieces, the flip-down-fence allows the user to cut without interfering with the blade guard. Without this feature, the guard would have to be removed. It prevents thin strips from getting caught under the rip fence. It is also used for making wide rips as it drops down to table height and supports the outside edge of the workpiece while cutting.

Safety & Accuracy Tune-up Features

Magnetic On/Off Switch

This saw features a magnetic on/off switch with a protruding off button design. If power is cut to the saw then restarting the power will not automatically turn the saw back on; the start button must be pressed again. This is a great feature to keep you safe and OSHA compliant on the job site! The user can also hit the protruding off button in an emergency by simply slapping the power button panel. Being able to quickly kill the power in an emergency situation is an important safety feature, especially on the jobsite. The design worked with any issues. We would still prefer a traditional-style, “off” paddle switch for emergency shut-offs since it’s more forgiving design. We appreciated the unmistakable green/red light indicator directly above the variable speed knob to clearly indicate the motor electronics status.

Ergonomics

The saw was comfortable to use for extended periods. The table height is set at a user-friendly 34.” This made it a breeze to use with infeed rollers as required. We also loved the integrated outfeed support. It can sometimes be a challenge to set up outfeed rollers on the jobsite if a level concrete pad isn’t available (who doesn’t hate when the outfeed roller causes the material to track out of line!). The integrated outfeed support was sturdy and worked great on longer, flexible trim pieces. Additionally, the rolling design made it very easy to move the saw around the jobsite. The wheels are large enough to roll over gravel as required with no issues.

Ease-of-Use Design Features | 10010 table saw

Table saws are not an overly complicated tool to use. Place the fence where you want it, lock it in place, raise the blade to the right height (about 1/8″ higher than materiel to be cut) and turn it on. The ability to quickly set them up and get cutting is essential for work efficiency. The Oliver Machinery 10010 is a very easy-to-use job site table saw with a few key strengths.

Tool-less Quick Change Functionality

Some of our favorite features of the Oliver Machinery 10010 job site Table saw were the quick-change features. You can easily change out the blade, riving knife, blade insert, or thin-cut L fence without tools. Time saved is money earned and the 10010 earned us some money in this department. First, there is an integrated locking lever for single-wrench blade changes. Having caught our fingers between 2 wrenches too often when changing a table saw blade, we appreciated this feature.

There is also a twist lock on the blade insert cover. This locks both the front and back of the insert in place and prevents it from coming loose when cutting OR transporting. Next, the lever to secure and release the riving knife or spanner/blade guard assembly works flawlessly. We’ve had other job site table saws in the past where it took a lot of effort to release the lever. This is not the case with the 10010 table saw.

Overall Adjustability

The knobs, wheels, locking levers, and thumbscrews are pretty straight-forward on the Oliver Machinery 10010. We started with the blade height and blade angle adjustment handles. The blade height adjustment wheel, like most job site table saws, is centrally located on the front of the saw. It has a smooth rotating action and was easy to grip and adjust. It is molded out of high-strength plastic. We would have preferred it was made of metal to reduce the risk of it getting damaged on-site but it was still pretty rugged. The blade height handle has no locking feature which was a bit surprising. The blade height stayed true during cutting, however, so it didn’t have a negative impact on our testing. The bevel angle locking lever turns parallel to the circumference of the blade height adjustment wheel. You simply unlock the height handle and push the handle assembly left or right to the desired angle. It locked securely and we like that the wheel offered some protection of the plastic locking lever.

The rack and pinion carriage lock thumbscrew on the front, right bolt position was easy to grip and tighten. The fence cutting width knob made for easy and very precise adjustments to the overall rip width. The location of the knob was convenient and didn’t interfere with any cutting done on the job site. The locking lever for the rack-and-pinion fence is found just bellow the saw’s tabletop on the right-hand side. It did a great job of securely holding the fence in place and was easy to reach.

Mobile, Rolling Stand

The stand on the 10010 is on par with most rolling table saw stands. It’s quick and easy to set up, reasonably sturdy, and best of all, stores in a compact, vertical configuration. It was a breeze to assemble. The wheels feel very rugged and we like that the 10010’s tabletop is still usable without the legs extended. The entire stand is very lightweight and incredibly easy to use. The outward-facing angle of the legs creates a wide and sturdy base for such a lightweight aluminum stand. The legs fold underneath the stand for quick, tool-free set-up and takedown on the job site.

One of the few issues we had with the stand set-up was that the spring-loaded locking buttons got stuck when recessed and took a little wiggling to work free and catch in the locking holes. Unlike other job site table saw designs, the Oliver Machinery 10010 table saw doesn’t have levers on the inside of the legs for easy button depression; you have to directly push the button. This was a bit difficult on the legs folded up behind the wheels. We had the bend our wrist to reach behind the wheel. Not a huge deal as we didn’t collapse the legs often during the day, but still a minor distraction.

Accessory Storage

Oliver Machinery clearly made an effort to make it easy and convenient to store all the 10010’s accessories. One of my pet peeves on the job site is wasting time looking for the blade guard and riving knife or miter gauge. The blade guard must be removed for non-through cuts like a dado. Unsurprisingly, they sometimes don’t make it back on the saw and seem to disappear. Having a dedicated storage location for the guard makes that much less likely to happen. The on-board storage also keeps the accessories secure during transport. There’s a place to store the fence, wrench, blade guard, riving knife, miter gauge, push stick, and anti-kickback pawls.

Fence, Anti-kickback paws, and Miter gauge stored

The biggest knock on the 10010’s on-board tool storage is that there is no place to store the blade or sanding disc. This was a bit frustrating because the saw comes with multiple 10″ consumables standard. This is a non-factor for blade-only-designed jobsite saws. Because of the 10010’s awesome versatility with a sanding disc attachment, we would’ve like to see a place to store it to prevent the risk of accidental misplacement on-site. It also took us a minute to find out how to store the riving knife and blade guard since the manual didn’t do the greatest job of illustrating it. Once we figured it out though, it works excellent!

Dust Collection

The Oliver Machinery 10010 Table Saw has a 2 1/2″ dust port for dust collection. The port is located below and behind the tabletop. The 2-1/2″ dust port connects to the area just below the blade (standard location). It works well when connected to a job site vacuum. It collects about 80% of the dust depending on the material you’re cutting. Unlike other job site table saws, the Oliver Machinery 10010 doesn’t have a 1 1/4″ dust port on the blade guard. This isn’t a huge deal to us, however, as the blade guard dust collector feature can is sometimes more of a hassle than it’s worth. It can get in the way of material feeding past the blade. It also requires a second, smaller dust collector or a specialized Y-split which decreases the primary 2 1/2″ port suction and effectiveness.

Cutting Capacity | 10010 table saw

The Oliver Machinery Model 10010 offers ample cut capacity for a job site table saw. This saw offers an impressive 28″ rip capacity to the right of the blade. This is in line with the industry average for a job site table saw rip capacity. To reach the max rip capacity, the fence must be moved to the far set of mounting bolts (see the ease of adjustability section above). We found the rip capacity to be sufficient for all tasks we performed on the job site, even if it’s not the greatest among job site table saws.

- @ 90 degrees – 3 1/8″

- @ 45 degrees – 2 1/4″

Overall Impression |Oliver Machinery 10010 Table Saw

Oliver Machinery has a great offering in the model 10010 10″ portable table saw. It has all the features we love in top-competitor brands and then some. The variable-speed motor is awesome. The versatility of turning the “saw” into a disc sander is ingenious (even if not used as frequently). The constant torque motor works great and you can hear the consistent RPMs easily while cutting. We are also big fans of the rack-and-pinion fence and integration of a flip-down this rip fence feature. Lastly, the adjustable rear stock support is fantastic. We have a couple of recommendations for potential future improvements. First, the 10010 would be well served with an on-board blade storage option. We also recommend looking into the locking button wheel obstruction issue noted on the mobile base. These are minor recommendations and overall we loved the Oliver Machinery 10010 10″ jobsite table saw’s design, performance, and versatility.

Oliver Machinery Oliver Machinery Table Saw Model 10010

About the author

14 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Great rundown! Did you happen to measure the flatness of the table like you did for the head-to-head models?

Brooks, just remeasured the table flatness, and here are the numbers… side to side 1/64″ center gap with minimal cupping in the middle. Front to back 1/8″ on either end with a crown in the middle. That being said I would be much more concerned if the side-to-side flatness was off significantly. As the board travel front to back for rip cuts it moved smoothly along the surface and the crowning had zero effects on any rip or miter cuts I did. Great question and thanks for the feedback! Ben

Thanks for taking the time!

So with it said, how is it to the overall with the comparison with hitachi or delta in the testing you guys did such an awesome job with for job site saws. Gotta get a new to replace my 1998 ridgid. Accuracy? Or tune up

Help?

Skip, Unfortunately, we don’t keep the head-to-head saws in storage so we really have no way to do a direct comparison. The data in the article is the data tested for all the head-to-head saws. The accuracy with the Oliver Machinery is quite comparible to both the Hitachi or Delta. It is a fully adjustable saw so I was able to square up the rip fence and miter gauges to within 1/64″ which met my required tolerances for the finished cuts I was doing. I use a Wixey digital angle gauge to set my blade bevels and have for years so the bevel was within .01 degrees according to my gauge. I also use brass set-up blocks or my digital vernier caliper for blade height settings but only when I require really precise dado cuts. For what it’s worth, I replaced my circa 2014 Ridgid job site saw with this and haven’t had a single regret. Thanks for reading! Ben

Good review. I recently purchased my first Oliver tool, and have been impressed. After doing some research, I discovered that Oliver is at least party owned by Geetech. Geetech is the Taiwanese company that manufacturers woodworking equipment for Powermatic, Jet, Laguna, Grizzly, and SawStop. It seems that they manufacturer equipment to high specs, and then sell it under the Oliver name. I would highly recommend their tools.

Nice insight, this explains my Oliver 12.5″ Surface planner (I call him Olly) has the identical Form Factor as the Laguna. I just took delivery of Olly and look forward to using the upgraded head & Wixey DRO.

Appears to be the same saw as the Grizzly benchtop. From pictures of both and specs I could find no differences.

interesting – didn’t know that

This is the same table saw sold by Grizzly, DeWalt, and quite a few others with different names pasted on w/decals. Same chinese junk.

Would have liked to see some of the accuracy/precision measurements that were done in the 2018 comprehensive review of jobsite saws. From what anecdotal info I’ve been able to gather, this saw would have been in the middle of that pack in terms of its precision.

Ben! It’s great to run across your name on this review. Hope things are well. This looks like a great saw

So Ben, I’m thinking about purchasing this saw, but your review is the only one out there. I’m wondering if you have any long term use experience you’d like to share about it. Has it held up? Is the fence still square after being used? Has the lack of table flatness become a problem for you?

Eric,

Thanks for asking. This saw has held up well overall. But truth be told it’s taken on a secondary role over the past year as a dado-dedicated saw due to its portability, small footprint, and other saws we’ve tested since. That’s not a knock on it though… The constant torque feature has proven to produce consistent operating over time. The leg design with the detent buttons can be a bit tedious and still isn’t my favorite but that a minor note. The rack and pinion fence has held up well. I’ve had to re-square it a few times but that’s easily done and on par with other similarly designed job site saws we’ve tested; common to mobile saws getting moved around combined with aluminum fence components. It really boils down to what you’ll primarily be using the saw for. But if you’re comparing it directly to other jobsite saws it still compares favorably in my opinion. And I wouldn’t have any regrets today about buying this saw then based on its overall performance. Hope this helps! -Ben