Evolution Powertools Metal Miter Saw Review

Evolution Powertools 14 in. Metal Cutting Miter Saw, 120V/15A (Model S355MCS)

Evolution Powertools 14" Metal Miter Saw

Features and Specifications | Evolution Powertools Chop Saw

Features:

- Pivoting cutter head saves space and decreases overall material handling

- 3-position cutter head can be adjusted for various materials

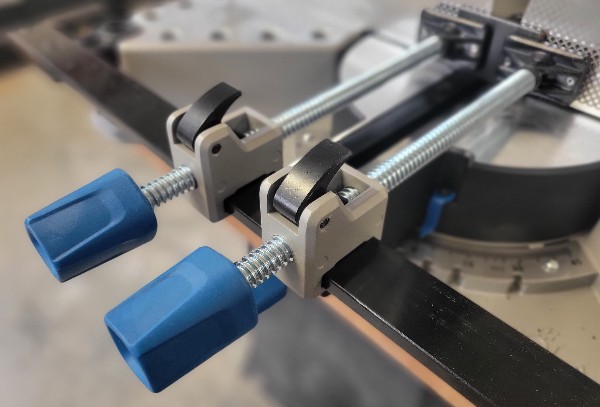

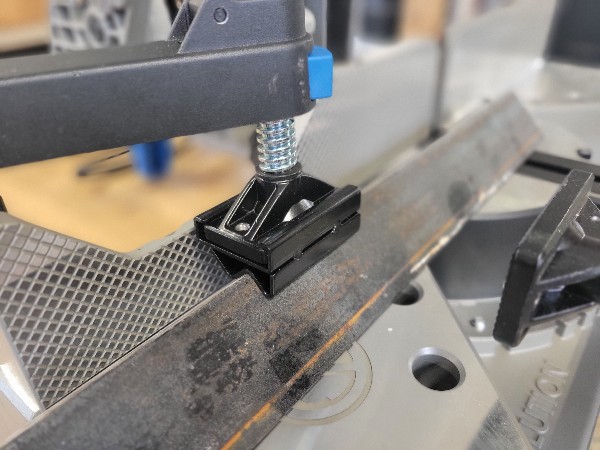

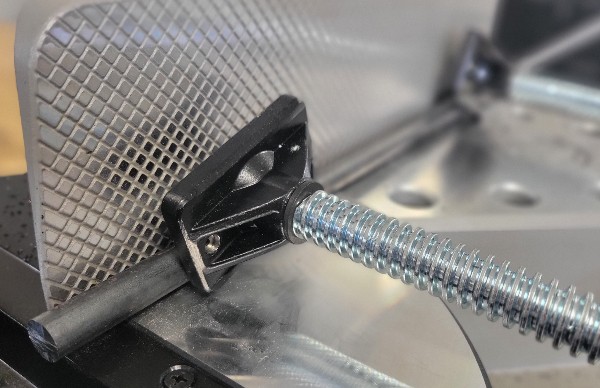

- 3x Quick release clamps (1x top & 2x front) w/ slide on V-blocks

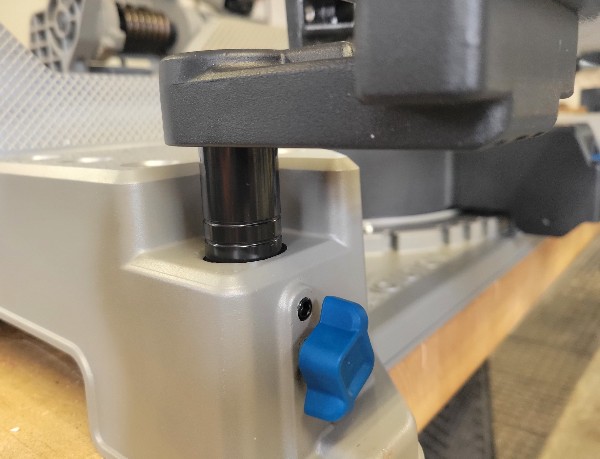

- Height-adjustable front clamp rail

- Removable ‘V’ block for secure clamping of round & square tube

- Ambidextrous handle design

- Material is secured by knurled fence & base includes bench dog holes

Specifications:

- Motor: 120 Volts/15A

- RPMs (No Load): 1450

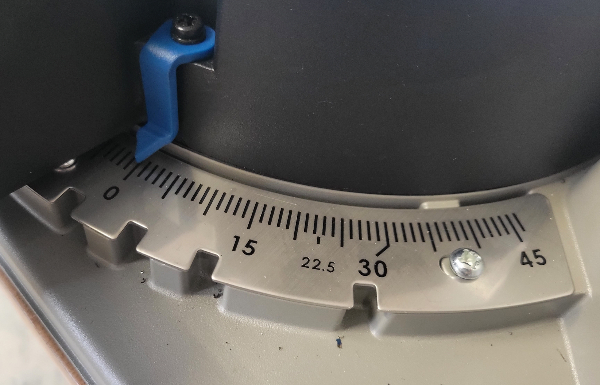

- Bevel Range: +/-46 degrees

- Positive Stops (+/-): 0°, 15°, 22.5°, 30°, & 45°

- Blade diameter: 14 in.

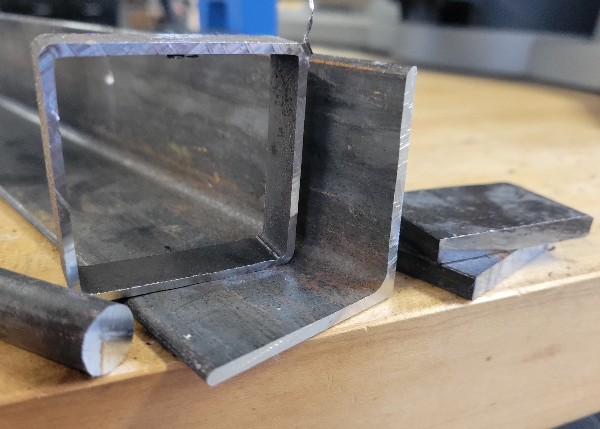

- Mild Steel Plate (Max Thickness): 1/2 in.

- Square Tube at 90°: 4 3/4 x 4 3/4 in.

- Square Tube at 45° (ML): 4 x 4 in.

- Square Tube at 45° (MR): 1 3/4 x 1 3/4 in.

- Rectangle Tube at 90°: 6 1/2 x 4 in.

- Rectangle Tube at 45°: 4 1/2 x 1 3/4 in.

- Round Tube at 90° (D): 4 3/4 in.

- Round Tube at 45° (D): 4 in.

- Tool body weight: 77 lbs.

Power & Performance

Torque and Motor Performance

Sustained power and torque and critical factors in metal cutting since blade slowdown or torque loss can have a variety of negative effects. Since the Evolution Powertools Metal Cutting Chop Saw (Model S355MCS) is a corded, 120V 15A tool, we expected consistent power from the motor. That’s what we got. This saw smoothly cut all shapes and sizes of steel we used it on. The motor never bogged down or seemed to strain to cut. The lower RPMs helped optimize the torque in this respect. So when Evolution Powertools explains that they found 1450 RPMs to be just right for mild steel cutting, the performance backed it up. In addition, the motor didn’t get overly hot even during prolonged cutting periods.

As a general fact (and as explained in a previous review on the S380CPS) cold cut saw blades vs. abrasive cut off saw are quite expensive ($80+ vs $6-8). But you get what you pay for… and for a few reasons:

- Longer Life. The 14 in. Evolution blades provided have Tungsten-Carbide tips and are very easy to load

- Cleaner edges. This is because the blade doesn’t flex mid cut like a 14 in. abrasive cutoff wheel. This produces accurate and ready-to-weld cuts

- Heat dissipation. Heat is transferred to the metal shavings vs. the blade. Extends blade life and creates less warpage over prolonged use

Blade Alignment

One of the issues we’ve noted with other metal chop saws is the blade alignment. They are sometimes not centered on the blade slot. This makes eyeball alignment trickier. The Evolution S355MCS blade was about 1/16 in. left of center from the blade recess slot. The S355MCS also doesn’t yet have a laser or shadow line alignment feature integrated into the saw. After a few cuts we were mentally calibrated to the 1/16 in. off set and were cutting within 1/64 in. without individually blade-measured cuts in no time. For the $850 price point, we would love to see Evolution Powertools add in an alignment system for increased (measured) cut accuracy. As currently designed however, operators can quickly be repeatedly accurate with minimal training.

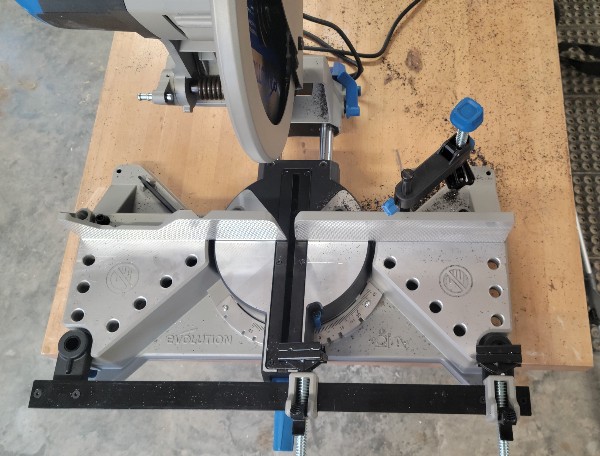

Miter Gauge Performance

This earned its own section for a reason since this is what sets the Evolution Powertools Metal Chop Saw (model S355MCS) apart in the metal cutting business. The ability to use pre-set detents to accurately and quickly adjust your cutting angle is something previously offered by a high-end, liquid cooled cold saw or metal cutting band saw. Those cost much more that the S355MCS.

And the accuracy of the miter gauge is spot on. We used our handy digital angle finder to double check the S355MCS’s accuracy out of the box and found it to be 90.0° on the dot. Equally impressive is the vertical gap minimization. Simply out, this exceeds any accuracy required for an immediate production-quality tack and weld.

Even more so than a wood miter saw, the mitering function of the S355MCS is a real time saver. Why? Because moving comparatively heavy pieces of steel is not as easily done as their lighter wood counterparts. And until this saw was introduced a saw operator had completely remove the material, adjust the cutting fence, and then reload and secure the piece of metal to be cut. It was time consuming. And it meant handling heavy materials (and usually support stands) more frequently.

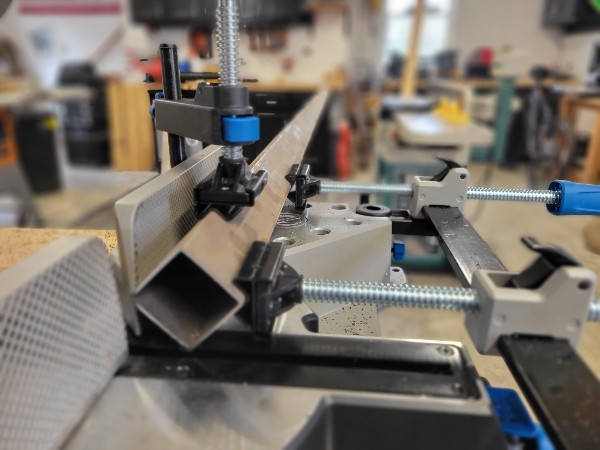

Material Size Limitations

There is one drawback to the miter design when cutting full 45° cuts with the saw blade tilted to the Right. And it first caught our attention when looking at the saw specs. The S355MCS can’t cut material wider than 1 3/4 in. on this side because unless the motor is set to the furthest back position the saw head protrudes past the fence. This is an issue when cutting angle since cutting mirror angles in any angle over 1 3/4″ wide will require you to flip and brace the piece to cut the opposite angle. To Evolution Powertool’s credit this is not a hidden but flaw but an openly acknowledged design limitation. We’d also like to point out that the standard chop saw design with an adjustable fence (not cutter head) only adjust in a single direction. So even with the limited range on the right side its still a great upgrade.

Key Design & Ergonomic Features

3-Position Cutter Head

Not only does the cutter head pivot to each side but it also adjusts forward and backwards. Before you make too many comparisons to a wood-cutting miter saw though, it does NOT slide. It can be locked into one of three positions. These positions increase overall safety and maximize the material size to be cut. You just adjust the blade so it’s as centered as possible on the material. Changing the position is extremely easy (and tool-free). First, release the locking lever and pull the spring-loaded pin back while sliding the cutter head assembly. The back balance foot also serves as a rail endcap to prevent the operator from sliding the cutter head off. Its a simple but very secure and effective design. Centering the blade greatly reduced material chatter keeping the operator as safe as possible. We like that!

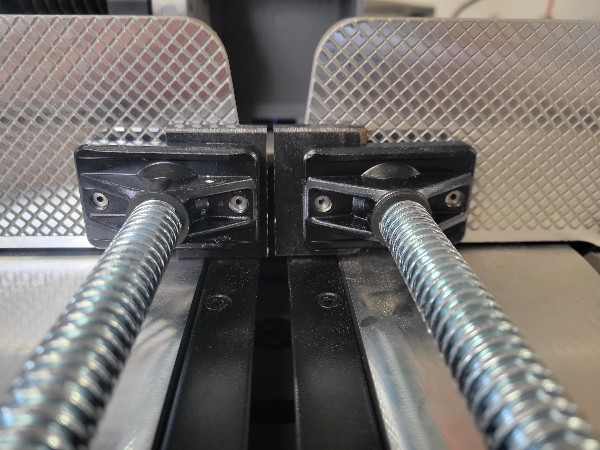

Quick-Release Clamps

The quick release clamps on the S355MCS are one of the best features of the whole saw. They offer adjustability like no other clamps we’ve used. The clamps are fully adjustable in both height and horizontal positioning. They accomplish this by sliding along a front, height-adjustable rail. The height is adjusted via thumb screws so there is no tool to lose. The posts also have detent markings every 1/4 in which makes evenly aligning both sides very simple.

Our favorite aspect is that both clamps can be secured on the same side of the blade. This means that a piece of metal can be secured at 2 points on the same side of the blade. Dual clamping severely reduces moving and rotating of the piece during cutting. This means a much cleaner and safer cut. All 3 clamps also include a slide on/off v-block which works wonderfully to secure round or angled materials for cutting!

Our favorite aspect is that both clamps can be secured on the same side of the blade. This means that a piece of metal can be secured at 2 points on the same side of the blade. Dual clamping severely reduces moving and rotating of the piece during cutting. This means a much cleaner and safer cut. All 3 clamps also include a slide on/off v-block which works wonderfully to secure round or angled materials for cutting!

The hold-down clamp is ALSO quick release and can be mounted in one of five positions. We wish the wood miter saws would incorporate this feature, although truth be told we don’t use a hold down clamp when cutting wood nearly as much as when cutting metal.

One note however is that when mounted in the left side holes, the hold down post obstructs the motor housing, preventing the saw from completing a cut. We’re not sure why a hold location was included here… We were able to complete all our tasks using the vertical hold down mounted on the right so it wasn’t a deal breaker.

Knurled Fence

In addition to the clamps, the Evolution Powertools Metal Miter Saw (S355MCS) features a knurled fence. This is more than a visual feature. A knurled fence increases the overall contact pressure of the material against the fence. This creates a more secure hold and also gives a better gripping texture. This is an excellent safety feature when cutting round metal. As the blade teeth “bite into” the material some of the rotational force is transferred from the blade to the material. If not securely clamped there is a risk of the material spinning in the saw. Not good! The knurled fence greatly reduces this risk and makes for a cleaner cut too.

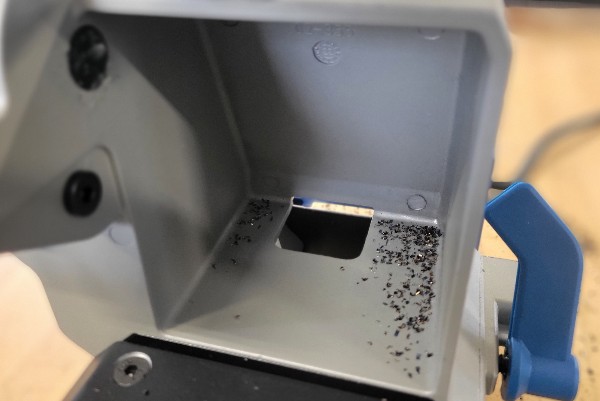

Chip Deflector

The S355MCS is designed with a chip deflector as opposed to a vacuum port. This is not a knock on this saw. Because flying pieces of metal are heavier than smaller pieces of sawdust, they often have enough force to escape the vacuum suction zone. Even for a high CFM rated dust collector. They also pose a greater risk to a vulnerable human eye. The chip deflector is designed to project the chips away and downward from the operator. Evolution Powertools also sells a magnetic pick up tool which is the preferred option for collecting ferrous metal chips.

With this being said, the deflector worked ok keeping the chips away when cutting. It might work a bit better if the back was angles more aggressively downward with a bigger exit port. Our estimate that about 85% of the chips ended up behind and under the saw. Of the 15% that ended up in front, few were directed upwards towards our faces.

Blade Replacement Design

The blade replacement design is pretty standard for a chop saw. And thankfully Evolution Powertools includes on-tool storage for the required Allen wrench. It is a 2-part process. First, free up the arbor cover plate. Then use the locking pin to secure the blade from rotating and loosen the Allen bolt holding the blade in place. We like the arbor cover plate as it helps keep the Allen bolt hole cleaner from debris.

Portability & Versatility

The S355MCS is not a light saw at 77 lbs. But it is definitely light enough to bring on a job site as required. It is also designed to fit onto a universal miter saw jobsite stand. Evolution Powertools has yet to release one specifically designed for this saw… but it’s coming. If we get the chance to mount this on one we’ll add additional comments then. For now, be confident that this is an easily portable (via a rugged top carry handle) and stand-mountable saw that can be used on a jobsite with minimal effort. Also be aware that it does NOT fit onto the Evolution Powertools Universal Chop Saw Stand. So if you already have one or have looked at one you will need to go another route.

The last versatility feature we would be remiss in not mentioning is the integrated bench dog design. The base, on both the left and right sides have a total of 7 benchdog holes built into them. This gives the user even more options for securing material during cutting. We were pretty impressed with the clamp system though and didn’t use them in the course of our jobs. But they are there and may pay dividends in different circumstances.

Final Thoughts | Evolution Powertools Chop Saw

The Evolution Powertools Metal Miter Saw (model S355MCS) is a no brainer for any metal fabricator or PRO builder who finds themselves cutting metal on the jobsite. It allows for repeatable and accurate cut on par with any wood cutting miter saw. The cut edges are burr-free and installation or weld ready with no grinding required. This means considerable time saved and work completed. The pivoting head also means less material handling in constricted spaces. And the highly-adjustable QR clamps combined with the knurled fence keep your materials firmly in place so you can cut with peace of mind. At $850 this is a great value and one that we think many of our followers will thank us for making!

Evolution Powertools Evolution Powertools 14" Metal Miter Saw

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.