Bosch GKT 13-225L Track Saw Review

Bosch GKT 13-225L Plunge Saw

I have owned a Triton track saw for three plus years. At the time I bought it, it was a great addition to my shop. Since owning a track saw, I have abandoned using my table saw for breaking down sheet goods. For me, the track saw is more accurate, easier and safer to use. The Triton has done me great service and I really like that unit.

But when I had an opportunity to test out the 6-1/2″ Bosch GKT 13-225L Track Saw, I jumped at the chance.

But when I had an opportunity to test out the 6-1/2″ Bosch GKT 13-225L Track Saw, I jumped at the chance.

Bosch is a relative late comer to the track saw market in the US. However, its reputation in Europe preceded it across the pond. The saw has a heritage derived from the popular and well-regarded Mafell track saws. So my expectations were high and the Bosch GKT13-225L did not disappoint me.

Bosch GKT 13-225L Track Saw Specifications

- Amperage 13 amp

- Arbor Size 20 mm

- Blade Diameter 6.5 inches

- Max Cut Depth 2.25 inches

- Case Type L-BOXX-4

- Saw Cord Length 12 feet

- Country of Origin Germany (DE)

- Height 9.45 inches

- Length 14.4 inches

- Width 9.5 inches

- Weight 10.34 lbs

- No Load RPM 3,600-6,250 rpm

- Voltage 120V

- Warranty 1-Year Limited Warranty

- Depth Scale Units Metric and Imperial (inches

Bosch Track Saw – First Impression

From the first time I opened the L-BOXX-4, I saw the quality, fit and finish of the tool. I would put the Bosch GKT13-225L up against any other saw for comparison. I liked the overall fit and finish, the quality of the machined surfaces, the easy-to-read scales and the 12-foot long cord.

When I fitted the saw to its tracks for the first time, the Bosch saw ‘system’ impressed me with the precision of the fit between the saw body and the tracks. There was no run-out play between the saw and the track. I tried to detect any relative movement by twisting the saw and found none. This precise fit is due to two adjustment knobs on the foot of the saw to ensure a precise fit between the aluminum extrusion and the saw. These are adjustable to take out any relative movement with cam-actuated arms that close any gap in the fit. In fact, you can adjust these knobs to be so tight that you cannot move the saw along the track. No concern there, as I easily found the sweet spot between an accurate fit and the ease of moving the saw along the track.

Bosch Track System

One of the keys to the success of a track saw is the track system, itself. I have to say that the Bosch GKT 13-225L Track Saw excels in this area. Bosch made the tracks from an extremely high quality aluminum extrusion. In addition, Bosch did a great job optimizing the usability features of this track system. For example, the tracks come with installed plastic end caps. These help either an attached vacuum hose or the electric cord slide easily during a cut if they contact the end of the extrusion. Until I used the Bosch tracks, I forgot how many times I had to stop because the corrugations of my vacuum hose or electrical cord becoming caught on the sharp track ends of my old saw.

Joining Tracks

Another example of the excellent track features is the connector that joins two tracks. My previous saw (and also true for Makita and Festool tracks) used connectors that put vertical pressure on the t-slots in order to join two sections of track. While this worked to hold the tracks together, the connectors did not assist in making sure that the tracks aligned their cutting edges.

Put another way, I could set the tracks together and have a slight misalignment at the cutting strip. With the Bosch system of connection, the connector puts pressure in a horizontal manner on the portion of the extrusions to ensure that the tracks align perfectly. Bosch does this alignment with four cams such that two cams align each track and the top of the connector aligns the tracks with each other. I tried to misalign the Bosch tracks and as I tightened the connector, the connector took out all of the inaccuracy. Impressive to say the least.

Finally, I really liked the feature that the track connector does not interfere in any way with the use of quick clamps. I experienced many times with the old track system where I had to shift the track up or down the cut line because my t-slot track clamps hit the underside connector. (Yes, I did put the tracks together with a connector in both the top and bottom T-slots. I did not like the way the tracks fit together with just using the top t-slot.) With the Bosch connector, there is no way that he connector and clamps can get in each other’s’ way. The clamps are free to travel the entire length of the tracks.

The Bosch GKT13-225L track saw left me with an excellent set of first impressions and I was looking forward to putting it to good use.

Using The Bosch GKT 13-225L Track Saw

The opportunity presented itself for me to use the Bosch track saw on a small project to make some fixtures for an upcoming TBB 12v Head-to-Head review. I had to rip down four sheets of plywood, AC and CDX, into smaller quarter-width pieces and I used the Bosch GKT13-225L track saw for this work.

To begin, I started ripping the length of the 4×8 sheets in half and then ripped them down to a little less than 12 inch widths. Intentionally, I started with the roughest sheet goods and I ripped the CDX sheets first and the cut edges were a furniture-making quality cut.

Dust Collection

For dust collection, I easily fitted the track saw to a Bosch dust collector and the Bosch vacuum hose fit with no adapters. The combination of these two Bosch pieces of equipment produced a virtual dust free result. After cutting down all of the sheets into 12 inch widths, I did not observe even a noticeable amount of dust on my cutting table. Unlike my other track saw, Bosch provided a dust shroud at the front of the saw where the sawdust would exit the material. I pulled this shroud down to the top of the material and saw no dust generated at that location. The saw has a swiveling hose port to allow the user the control of the position of the connected hose. An added feature is that the hose swivel has positive stops along the range of rotation to keep the hose position fixed. After cutting down eight sheets of plywood, the following picture shows the extent of the sawdust I swept together from the top of my workbench.

Bevel Cutting

When I was done cutting the H2H materials, I tried the saw on bevel cuts, First, the Bosch GKT 13-225L Track Saw has the power to easily cut through the additional material. In addition, Bosch designed the saw with a pivot point that ensures that the user will not need to worry about where to position the tracks for a bevel. The Bosch tracks do not need to be positioned any differently than a non-bevel cut. The GKT 13-225L provides bevel cuts from -1° (for slight undercuts) to +47° cuts. My bevel cuts were also flawless with no blade marks or variations in the surface of the cut.

Bosch designed this saw to have two adjustment clamping screws at either end of the saw body. The adjustment scale is at the front of the saw. That scale shows the adjustment will range from -1 degree for undercuts to 47 degrees. Interestingly, the detent that allows for increasing the range from 45 to 47 degrees is a button on the front scale that needs to be pressed to engage the extra degrees. The detent that allows for the -1 degree cut is in a similar position on the rear of the saw.

I wanted to see how accurate the 45 degree factory setting was and I checked it with a digital protractor. The reading was 45.1 degrees.

Quick Release Clamps

I also liked using the Bosch quick release clamps. These clamps have a precise form that fits into the underside t-slot on the track extrusion. There is a higher level of precision when compared to a dovetail type clamp in my prior track saw. I even appreciated how Bosch provided an easy way to see where to install the clamps by leaving a small notch in the end caps of the track. That way, I could insert the clamps without having to go to the end of the track, bend down and look around at the end of a track to find the place where the T-slot is located.

This attention to detail and usability is why I am very impressed by the Bosch track saw.

Plunge Adjustment Mechanism

Good design improves the user’s experience. Bosch did a great job designing the plunge adjustment mechanism on the GKT13-225L. The adjustment mechanism works by depressing a latch and moving the depth stop to the correct setting. What I like about the Bosch design is that the latch is large enough for big thumbs to work the latch and that the scale is large enough to see and read. Both metric and imperial scales are on the saw body and the adjustment is in one millimeter increments. While these positions do not line up with the imperial measurements exactly, this allows for a very precise tolerance when setting the depth.

Depth Gauge Pointer

There is a red pointer to use in setting the depth. This pointer can be flipped around for two different readings. Why? Because Bosch designed this saw to be used with or without the track. The GKT13-225L has an optional rip fence that can be used for multiple cutoffs with no track. As a result, Bosch provided an easy way to adjust for those times when the saw will be sitting on top of the materials with no track underneath the saw. While this feature has its benefits, the user needs to check that the pointer is in the correct orientation or the depth of cut will be different.

Bosch did mark the red pointer with symbols to assist the user in ensuring the pointer is in the desired orientation. But I found the symbols somewhat confusing. For me there is an easy way to remember the pointer orientation. When the saw is used with the track, the depth setting needs to be greater to compensate for the thickness of the track. This means that the red pointer must indicate the lowest of its depth settings. Since I will mainly use the saw with the track(s), my normal operating position would be as shown in the following picture.

Constant Blade Speed

My former track saw used to slow down when I cut through thick materials or used it in a bevel setting. Not so with the Bosch track saw. The Bosch GKT 13-225L Track Saw draws a maximum of 1300 watts. The Bosch saw has the power to plow through the thickest materials I cut and uses advanced electronics to vary the power consumption and to produce a constant blade speed under load. Even if the user pushes the Bosch saw past its limits, the user cannot hurt the motor because it has an overload thermal protection that will cut out and protect the motor.

Additionally. the saw has a speed adjustment to vary the speed for different materials from 3,200 to 6,250 rpm.

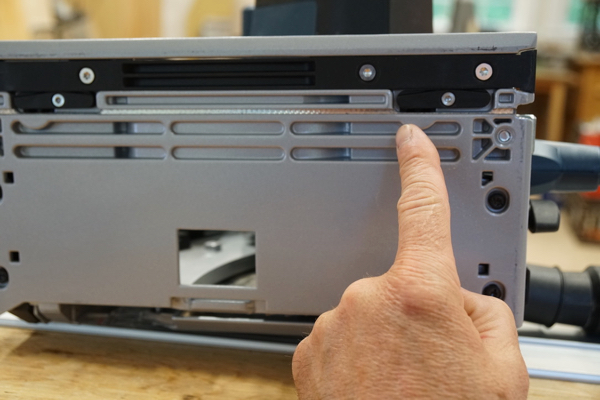

The GRK 13-225L has a plastic piece on the bottom of the shoe that serves a unique purpose. If you remove that insert, the Bosch saw will fit onto the Makita/Triton/Festool tracks! While I have to believe that a a user would have to fit a new cut strip to the other tracks to accommodate the different saw kerf position of the Bosch saw with a particular track. This interchangeable feature is certainly one that is not offered by other manufacturers. The following picture shows the Bosch GRK13-225L fitted to a Festool track.

Parallel Guide

Bosch also sells an accessory called a Parallelanschlag for the GRK 13-225L. This device (a.k.a. Parallel Guide) enables the user to rip small pieces with no track. The user now has a way to set the fence and make multiple cuts at the identical dimension. Clearly, this accessory makes the Bosch track saw closer in function to a table saw. I easily ripped a set of 2” wide strips off of a sheet of plywood. By my measurements, the parallel guide accessory enables cuts from a minimum of 1 11/16” to a maximum of 4 9/16”. The following picture shows the parallel guide fitted to my track saw.

Price

The old adage that you get what you pay for applies to the Bosch GRK13-225 track saw. This is an expensive system to purchase but I expect that I will be passing this Bosch kit down to my kids. But this saw delivers the quality that goes along with paying a high price to buy it.

I found the following pricing for the GRK13-225 at Ohio Power Tool’s website:

- GKT13-225L – Track Saw, Blade and L-Boxx Carrying Case – $599.00

- FSN1600 – Bosch 63 in Track Saw Track – $129.00

- FSN1100 – Bosch 43 in Track Saw Track – $99.00

- FSN800 – Bosch 31.5 in Track Saw Track – $79.00

- FSNKZW – Bosch Track QUick Clamps (2 pcs) – $65.00

- FSN1600X28 – Bosch 63 in Track Saw Tracks anc Connector Kit – $299.00

- FSNWAN – Bosch Track Miter Guide ( Not Tested by me) – $99.00

- GKTPA – Bosch Parallel Guide – $80.65

Stand Out Features

The things that stand out for me are the following:

- Precise fit between the track and the saw body with no backlash

- Track end caps that make the cords and hoses less tangle prone

- Track end caps with an indicator for where the track clamps attach

- Single pivot point so that bevel cuts use the same track strip cut position as non-bevel cuts

- Bevel cut extensions that allow -1 degree undercuts and up to 47 degree bevel cuts

- Track connectors that positively align the track sections

- Track connector that does not interfere with track clamps

- Electronic power control for constant blade speed under load and motor protection

- 12 foot long cord.

- Excellent dust control with an adjustable dust shroud at the blade exit location

- Plunge adjustment indicator that adjusts for conditions with and without tracks

- Saw body that adapts to work with Makita/ Triton/ Festool tracks

- Parallelanschlag that allows ripping small pieces without tracks.

Changing My Perspective On Track Saws

When I purchased a track saw three years ago, I thought I was all set with this type of tool. And for three years, I was satisfied with my purchase. I began to use my track saw instead of my table saw for cutting down sheet goods to size. Now, I even use a track saw to make a precise cross cut when a table saw is not available.

My experience with the Bosch GRK 13-225L has changed my perspective on track saws. The Bosch unit is a step up in precision, usability, power and features. It may be expensive, but I think the quality justifies the price. Overall, this is a very fine addition to my shop.

Bosch GKT 13-225L Track Saw VIDEO Review

About the author

1 Comment

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

I have a Mafell MT55CC and the only other track saw I would use would be another Mafell or the Bosch. I have been waiting for years to be able to buy Bosch branded Mafell accessories so I can save a little bit of money. From the sound of the motor I am guessing it’s basically a Mafell saw without the Cuprix or quick blade change.

On a side note the Tajima blades are about 2 mm smaller but they cut like butter. I have ripped a ton of 8/4 hickory with no issue in one pass and the cut is glue line quality or better.