Cordless Jobsite Table Saw Head-To-Head

Cordless Table Saw – DEWALT vs. Milwaukee

We recently tested portable job-site table saws in our Head-T0-Head to determine the Best Portable Jobsite Table Saw, however we excluded the cordless saws. In this head-to-head we’re pitting the two current cordless table saws against each other. The DEWALT 60V FlexVolt DCS7485T1 8-1/4″ against the Milwaukee M18 2736-21HD 8-1/4″. While these two saws look pretty similar they certainly are powered using very different voltages with the DEWALT using a 60V MAX (54 volt) battery pack and motor and the Milwaukee using an 18 volt pack and motor. While they use different voltages, they were both tested with the same total battery pack energy of 216 watt-hours.

Table Saw Evaluation Format

Just like our previous corded table saw head to head we’re testing the cordless table saws in the same format. For this evaluation, we broke things into several categories including: Precision & Accuracy, Performance (power), Price, and Ergonomics.

- Precision & Accuracy – In this category we evaluated the accuracy of the table saws straight out of the box, and how easy it is to make calibration adjustments. We also discuss the quality of the fence system as it relates to ripping accurate cuts.

- Performance – The performance evaluation took a very deep dive into the power of the saw motors and how well the saws managed different ripping materials including plywood, pressure treated Southern Yellow Pine 5/4 decking and IPE 3/4 decking. We measured saw RPM’s and Amps for each of the cutting materials under constant feed rates.

- Price – Price is always an important factor in determining which saw is best for a user. We’ve included the current pricing found online for each of the saws at the time of publication.

- Ergonomics – Ergonomics are really important to users and an important category to consider when purchasing any power tool. In addition to traditional ergonomics, we also included functionality in this category.

Cordless Table Saw Features & Specifications

Before we get into the testing this section includes the features and specifications for each of the two cordless table saws. As you’ll see the two saws offer nearly identical specifications with the only noticeable difference being speed blade and voltage. The size, weight, and features are so similar that you’d swear they were a red and yellow version of the same saw.

DEWALT DCS7485T1

- Voltage: 60 V MAX (54V nominal)

- Battery Pack (used in the tests): 60V 4 Ah pack (54V x 4 Ah = 216 Wh)

- Blade Size: 8-1/4″

- No Load Blade Speed: 5,800 RPM

- Rip Capacity – Right: 24″

- Rip Capacity – Left: 12″

- Max Depth of Cut at 90 Deg: 2-1/2″

- Max Depth of Cut at 45 Deg: 1-3/4″

- Weight: 48 lbs

- Weight of Bare Tool: 45 lbs

- Table Height with Stand: 33-3/8″

- Warranty: 3 Year Limited Warranty

Milwaukee 2736-21HD

- Voltage: 18 V nominal

- Battery Pack (used in the tests): 18V 12 Ah pack (18V x 12 Ah = 216 Wh)

- Blade Size: 8-1/4″

- No Load Blade Speed: 6,300 RPM

- Rip Capacity – Right: 24″

- Rip Capacity – Left: 12″

- Max Depth of Cut at 90 Deg: 2-1/2″

- Max Depth of Cut at 45 Deg: 1-3/4″

- Weight: 46 lbs

- Weight of Bare Tool: 43 lbs

- Table Height with Stand: 33-7/8″

- Warranty: 3 Year Limited Warranty

Cordless Table Saw Precision & Accuracy – Winner DEWALT

Once again we looked at the precision and accuracy of the saws out of the box. TBB compared the relative accuracy of these two test saws. How would the battery powered saws compare to each other? We measured the manufactured tolerances and ranked these saws for as-built accuracy.

What and How We Measured

To assess the manufactured accuracy of the saws, TBB looked at six areas to measure and compare: Table Flatness, Accuracy of 45 Deg. Stop, Accuracy of 90 Deg. Stop, Blade Parallel to Miter Slot, Fence Parallel to Miter Slot, and blade run-out.

Table Flatness

Table Flatness

We evaluated the flatness of the table by measuring the flatness by placing the edge of a precision ground flat bar across the table and placed feeler gauges in any gaps to measure any difference between the ground bar and the table. TBB took measurements in four directions. As the operator faces the saw, we measured the flatness at the arbor from front-to-rear; we measured the left-to right flatness at the arbor; we measured the flatness from the upper left-to-lower right table corners; and, finally, we measured the upper right-to-lower left flatness between the corners.

- Table Flatness Front To Back

- DEWALT: 0.0025″

- Milwaukee: 0.012″

- Table Flatness Left to Right

- Milwaukee: 0.01″

- DEWALT: 0.08″

- Table Flatness Lower Left to Upper Right

- Milwaukee: 0.015″

- DEWALT: 0.015″

- Table Flatness Upper Left to Lower Right

- DEWALT: 0.008″

- Milwaukee: 0.028″

The flatness results were close: DEWALT edged out Milwaukee by taking 2 out of the 4 measurements and one tie. As a point of reference, a sheet of paper is only 0.004″ thick.

Accuracy of 45 Deg. Stop

TBB measured the accuracy of the factory-set 45 degree stop by using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the table and calibrated the inclinometer to the table by zeroing out the gauge. After that calibration, the measurements shown on the gauge give a result that is relative to the saw table. We attached the gauge to the blade and used the saw mechanism to adjust the blade incline to the point at which the blade or trunnion hit the factory-set 45 degree stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every case, the result came out to within 0.1 degree of the prior test.

- DEWALT: 45.0 degrees

- Milwaukee: 46.3 degrees

Clearly the DEWALT took this category and the Milwaukee needed some adjustments.

Accuracy of Vertical 90 Deg. Stop

TBB measured the accuracy of the factory-set 90 degree stop by using a Wixey WR365 digital inclinometer. This device has an accuracy of 0.1 degree. We placed the Wixey gauge on the table and calibrated the inclinometer to the table by zeroing out the gauge. After that calibration, the measurements give a result that is relative to the saw table. We moved the blade to an approximate position of 70 degrees off vertical. TBB attached the gauge to the blade and used the saw mechanism to adjust the blade incline to the point at which the blade or trunnion hit the factory-set 90 degree vertical stop and recorded the measurement. TBB ran the test twice to ensure the repeatability of the measurement. In every case, the result came out to within 0.1 degree of the prior test.

- DEWALT: 90.0 degrees

- Milwaukee: 89.0 degrees

Clearly the DEWALT took this category and the Milwaukee needed some adjustments.

Blade Parallel to Miter Slot

TBB used an iGauging 35-125-4 digital dial indicator to measure the accuracy of the blade position to the table miter slot. This instrument has an accuracy of .0005 inches. As part of the table saw set-up, TBB installed a new blade in each saw and these never-before-used blades were used in the measurement test. To ensure that any wobble in the blade did not enter into the test results, TBB marked a single tooth as the reference point for the measurement. The blade position was moved to the front of the saw to allow the iGauging dial indicator to hit the tooth immediately behind the carbide tooth, The iGauging dial indicator was calibrated and the indicator had a reading of zero.

We rotated the blade to the rear of the saw to enable the dial indicator to contact the same location of the same tooth behind the carbide portion. We positioned the dial indicator to the rear of the saw placed onto the blade and the reading recorded. If the blade and the miter slot were closer together at the rear of the saw, the dial indicator has a negative reading. If the blade and the miter slot were father apart at the rear of the saw, the dial indicator showed a positive reading.

- DEWALT: 0.01″

- Milwaukee: 0.08″

Again, DEWALT took the category with a much closer tolerance.

Saw Fence Parallel to Miter Slot

The accuracy and safety of any given saw is dependent upon the blade being parallel to the rip fence. Since we tested the amount of difference in parallelism between the saw blade and the miter slot in the previous test, we need only to see if the miter slot is parallel to the rip fence to see if the saw has a parallel relationship between the blade and the rip fence.

TBB used the same iGauging 35-125-4 digital dial indicator to measure the accuracy of the as-delivered factory fence to the table miter slot. We started by placing the fence in a locked position about 1” away from the blade on the opposite side from the miter slot. We adjusted the throw of the dial indicator so that we took the readings on the indicator, as before, in the middle of the indicator’s range of movement.

We calibrated the iGauging dial indicator to a zero reading at the operator’s end of the rip fence so that we started out with a reading of zero. Next, we positioned the dial indicator to the rear of the saw placed onto the rip fence and took the reading.

If the fence and the miter slot were closer together at the rear of the saw, the dial indicator has a negative reading. If the blade and the miter slot were father apart at the rear of the saw, the dial indicator showed a positive reading. A negative reading meant that the materials being cut might be subject to being pinched and a kick back more likely to occur.

- DEWALT: 0.032″

- Milwaukee: 0.065″

Again, DEWALT took the category with a much closer tolerance.

Blade Runout

Blade Runout

One term you may hear when reading about table saw accuracy is blade runout. Runout is a term that describes whether or how much the outside edge of a saw blade wobbles while being held by the motor shaft. Sometimes, operators measure runout by using a saw blade. In that case, the very use of a saw blade presumes that the specific blade is perfect or nearly perfect in its flatness. In this comparison, we used the identical balde to measure the blade runout of the saws. This operation was necessary because our ground flat measurement plate is 10 inches in diameter and would not fit in these smaller saws. Using the same blade means the relative results will be an accurate measurement of the saw contribution to runout.

The same iGauging dial indicator provided the test measurements, only this time, the units were set to read out in mm. TBB noticed that in the initial saws, the movements were sufficiently small to need the smaller metric units. TBB placed the dial indicator on the starting position of the test blade and calibrated that position on the dial indicator to a reading of zero. We were very careful to rotate the test blade by using the outside rim so as not to impart any side-to-side force on the plate that might introduce errors into the measurements.

While we rotated the test blade, we recorded the maximum reading on the dial indicator. We validated each maximum reading by running the test for a second time and noting that the readings were consistent.

- Milwaukee: 0.0049″

- DEWALT: 0.0065″

For this test Milwaukee finished first.

Overall Cordless Table Saw Precision & Accuracy Results

We performed a total of 9 different measurements in this category and DEWALT took 6 of them, Milwaukee took 2, and one was a tie. DEWALT was the clear winner in this category.

Cordless Table Saw Performance – Winner (A Tie)

The million dollar question about any cordless table saw is how long will it run? We developed three different run-time tests to see how the two saws perform and how long they can run on a fully charged battery pack. These tests also allowed us to compare the saws on how well they “run” during very different cutting applications. The three tests included:

- Ripping 3/4″ Plywood

- Ripping 2×6 SPF Framing Lumber

- Ripping 3/4″ thick IPE Decking

We chose these three materials to help evaluate a wide range or applications and power demand on the table saws. The lightest “demand” being the 3/4″ plywood which is a fairly standard application for a jobsite table saw and also similar to ripping softwood trim like Pine and Poplar. Next we ripped 2×6 SPF framing lumber for a moderate “demand” application. Finally we wanted to see how the saws performed under a difficult “demand” application so we ripped the 1x IPE decking.

We really wanted to see if the different demand applications would show different results for the two drastically different voltage saws.

For this testing we used two different blades from DEWALT and Milwaukee. For each type of wood, we installed a new blade in each saw. We used the same blade for each test. For example, when we cut plywood, both saws used the DEWALT FlexVolt 24T blade. When we ripped the IPE decking both saws were using the Milwaukee 40T finish blade. And for the framing lumber tests we used another set of new DEWALT FlexVolt 24T blades.

The Milwaukee used an 18V, 12 Ah battery pack which is 18V x 12Ah = 216 Wh. The DEWALT used an 60V (54V nom), 4 Ah battery pack which is 54V x 4Ah = 216 Wh.

Run-time Results

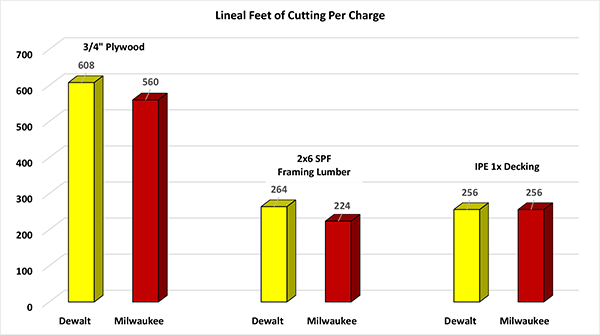

In the graphic above are the results from the three different run-time tests that we performed. The run-time results are very close. For the IPE decking both saws cut a total of 256 lineal feet of material. For the framing lumber, DEWALT cut approximately 40 lineal feet more than the Milwaukee with 264 lf compared to 224 lf. And lastly, for the plywood test DEWALT cut approximately 48 lineal feet more than the Milwaukee with 608 lf compared to 560 lf.

So the question really is do either of the saws out-perform the other when it comes to run-time? Clearly the DEWALT was a bit better than the Milwaukee but honestly the difference is so small that it’s virtually a tie. What’s more impressive is the amount of cuts these cordless tablesaws can do on a single charge. Each of the saws was able to make over 70 rip cuts in 3/4″ plywood (8′ long), approximately 30 rip cuts in 2x framing lumber (8′ long), and 32 rips in 3/4″ thick IPE decking (8′ long).

While these numbers certainly are not a big deal if you’re cutting ALL day long on the table saw, they are impressive for punch list and small trim jobs. Also, paired with a second battery it’s likely that most users can keep working all day.

Performance

While cutting all the material for the run-time testing we were able to get a good feel of the two saws and how they compare. Both saws feel very strong and didn’t have trouble cutting the materials we selected for the tests. More notably, everyone felt the Milwaukee cut much smoother and felt a bit stronger. The DEWALT felt like it was “chattering” at times while the Milwaukee cut smoothly and didn’t seem to be bogged down.

Overall Cordless Table Saw Performance

The run-time testing wasn’t much of a surprise to us as we figured that two saws using the same total battery pack energy should provide similar run-time results. While the DEWALT did slightly beat the Milwaukee in two of the tests, the difference really doesn’t change the overall production between the two. On the other hand, the Milwaukee felt like it ran much smoother compared to the DEWALT. At the end of the day we feel the performance of these two saws is too close to declare a winner.

Cordless Table Saw Ergonomics / Features – Winner Milwaukee

Both cordless table saws were compared and evaluated on several ergonomic and feature categories that we feel are important to end users.

- Weight – Both cordless table saws weigh in at just over 40 lbs (w/out battery); Milwaukee at 43 lbs and DEWALT at 45 lbs. Milwaukee wins by a slight margin.

- Blade Height Adjustment – The DEWALT saw takes 36 turns of the wheel to raise the blade to full height. The Milwaukee only takes 14 turns to raise the blade full height. Milwaukee is the clear winner with a much more efficient height adjustment design.

- Switch Design – The Milwaukee has a much better power switch design. One of our big gripes with the DEWALT saw is how the safety switch can easily turn off the saw just after turning the saw on. The switch cover falls down as you remove your fingers and the weight of the cover turns the saw off. The Milwaukee doesn’t suffer from this design issue and therefore is a much better design in our eyes.

- Blade Change – Milwaukee did a good job using an arbor lock so users only need one wrench to change blades. On the contrary, the DEWALT requires two wrenches which can be cumbersome and not as easy as the arbor lock design.

- Fence – Both saws use a rack-and-pinion fence design which we prefer

- Adjustments / Riving Knife – Milwaukee provides a tool free guard and riving knife design, by releasing a lever under the table the riving knife and guard can simply be pulled out. On the other hand, the DEWALT requires a user to take off the throat plate, remove riving knife lock knob then remove the riving knife or guard. This is a pretty big difference in our opinion.

- Stand Leg Adjustment – The Milwaukee stand does offer a leg leveler but it broke on us not long after putting the saw on a real jobsite. The folks at Milwaukee tell us they are working on an improved design to correct the lack of performance. The DEWALT stand doesn’t provide a feature for leveling the stand.

- Stand – Overall the stands are quite similar with one notable exception. The Milwaukee stand has a simple clamp that keeps the stand attached to the saw so you can carry the entire assembly as one, while the DEWALT does not which means users must move both separately.

- One-Key – Another big feature that Milwaukee offers that DEWALT does not is the One-Key technology. One-Key offers tool lock-out, tool tracking, and a robust asset management feature. This added value offers users peace of mind on busy jobsites.

Overall Milwaukee clearly spent some time looking at the features and ergonomics of the new saw. While both saws have similar features the Milwaukee edges them out in several categories.

Cordless Table Saw Pricing

Obviously pricing is a concern to any user so this category is always important. Below are current pricing for the saw, one battery, and the stand.

- Milwaukee – M18 Cordless Table Saw, Scissor Stand, 12 Ah battery pack and rapid charger: $628 UPDATED (at the original time of publishing we saw a promo with a free stand, that is no longer available so the pricing was adjusted to include the stand price of $79).

- DEWALT – 60V Cordless FlexVolt Table Saw, Scissor Stand, 12 Ah battery pack and charger: $710 *

- * Note: DEWALT isn’t selling any kits that we could find with everything in it so we had to price each item separately, whereas the Milwaukee is sold as a kit which is most likely why the pricing is so good.

The Milwaukee is slightly cheaper than DEWALT.

Best Cordless Table Saw

We seldom have a hard time picking a winner in Head-To-Head testing on TBB but this time the results are far too close. Both the DEWALT and Milwaukee Cordless Table Saws are very good. While the DEWALT offers a slight edge on run-time the Milwaukee has slightly better features and a lower price point. Also, for Milwaukee users this saw is a continuation and expansion of the M18 platform unlike the DEWALT platform that users must move up to the new FlexVolt line.

If you own either of these cordless platforms the selection for you is an easy one. These two saws look like they could be twins other than the paint schemes and their performance certainly matches their appearance.

While we know you guys expect a winner each time, but this was just too close. At the end of the day, these two saws are once again expanding the ever growing cordless job-site and cutting the cord!

Cordless Table Saw – DEWALT vs. Milwaukee

About the author

25 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Good review, thanks.

What were the results with the packed-in Milwaukee blade? Looks like you used the $ Milwaukee one and packed-in Dewalt one.

Not sure I understand the question? When we did any cut testing both machines used the same blade type.

Did you happen to test how the Milwaukee did with a lesser battery (5.0 or 9.0)? I was just curious how it did when I would need to make one or two more cuts and the 12.0 was being charged.

It will work fine, just reduced run-time.

It would be interesting to know if there is a difference in total linear feet cut using the factory installed blades for each unit. Seems like the development engineers may have optimized their own unit’s blade selection to their system since each operate at different RPMs. I am somewhat unclear what the value is to checking the accuracy of these units unless (like the tables themselves) it is not correctable. I mean I think its ridiculous to think your going to buy one of these and not do your due diligence to check and adjust the blade 90/45 degree setting and fence and miter gauge straightness or accuracy. It’s data but somewhat meaningless considering how far and how well it was treated in shipment could impact these figures and that they are easily corrected I’m just not sure the value. Table flatness and spindle runout are significantly more difficult to correct by the end user and are true factors that would tend to indicate manufacturing tolerances and QA acceptability. Such a great time we live in to be able to tote one of these home I love it! Thanks for your thorough review!

The blades we used were indeed blades that were designed with the cordless saws in mind. That’s why we did tests with both blades.

I know I’m kinda late getting here but just now decided I needed one. Hoping you will do another comparison soon since more brands are now available, sure do wish they would all switch to 10” blades though.A couple questions I hope you can answer.

1. Will they accept a 6”stackable dado .

2. What size is the arbor.

3. I hate those thin kerf blades because they distort so much, do they have the power to use a standard 1/8” +- kerf blade.

Love your reviews!!!!!

Bill – We probably won’t do another anytime soon as there’s really only one more on the market now, the Metabo HPT MultiVolt.

1. I do not believe they take a stacked dado.

2. Both are 5/8″ arbors if memory serves me right.

3. These saws are highly optimized for running on a battery. The thin kerf blade is part of that, you get FAR more run time using the thing kerf blade.

Bottom line these saws are not meant to replace a more robust 10″ saw. These have their place and we use them a lot. Now, if you want the best of both worlds than the Metabo HPT is worth a look. That’s a true 10″ saw, and it can run on both battery or AC power. It’s a 36V battery platform. We’ve tried the saw and it’s a nice saw for sure.

Good luck

Thank you very much for replying. I was under the impression most of the major brands had come out with cordless saws. I’m retired from having a millwork company and I now live in the Philippines where good quality power tools and cordless power tools are almost non existent. I brought a container with me and a model 66 table saw but have no place so far to put it for using. I really wish I had brought a portable saw but didn’t but now with the battery saws coming out and the voltage difference between countries it really seems it would do what I need . I’ll check into the metabo saw but kinda hate to add another brand since I have so many red batteries already.Red would probably work but really would like to be able to use a dado rather than a router for everything. Non related but I’ve been waiting for the Milwaukee cordless framing nailer to come out, last I heard it was coming out last Oct. Really want that rather than the metabo one, have you heard anything about it being released? I didn’t mean to add more questions to the comment and I won’t reply again other than to say thanks!

next month (June) 2020

Thanks for the great review. Looking at the blade runout numbers these cordless table saws have about 10 times the runout of corded portable saws in the other TBB test. Was your decimal in the right place?

Mark – Great catch! Thank you, I double checked our data and you were absolutely correct.

Hello Todd,

I hope this message finds you well in the midst of Corona Virus

I am a UK based carpenter who watches your tool reviews and other videos posted online – Love your work!

Following your review on the best cordless table saw I have just purchased the Milwaukee M18 saw which will be here any day now. One of the deciding factors for my purchase was the fact that the M18 will take a Dado-Stack head – however, I cannot find anywhere that stocks the Dado throat plate (Milwaukee US part No: 14-67-0010) Can you offer any assistance in how I can buy one of these and get it shipped out to the UK

Thanks in advance for any help you may be able to offer

Keep up the good work and stay safe

Gerard Greenan

Gerard – Thanks for the kind words. It’s our understanding you can purchase from Milwaukee. See below. Good luck!

Genuine Milwaukee Tool service parts and accessories are available for purchase by calling and talking with our Global Customer Service Representatives at 1.800.SAWDUST [1.800.729.3878], select prompt #2, Monday – Friday, 7:00AM – 6:30PM, Central Time. We accept most major credit cards [American Express, Discover Card, MasterCard or Visa] for payment.

I’m a diy guy around the house. I’m looking for a table saw that will serve me good for all sorts of jobs – from cutting plywood to trim. I’m very interested in the Milwaukee because I like the brand and assortment of battery tool options. Is this table saw worth the price? One of my concerns is the battery strength near the end of its life. Is the power and blade speed still there through all cuts, or does it stall, snag and get hung up?

If you want a cordless tablesaw then it’s a great saw. It’s designed to shut down when the battery gets low, so it doesn’t really bog down near the end. We use them on the job all the time and they are a great saw.

Do you prefer corded over cordless? My concern is the cordless variant meaning batteries eventually getting phased out over time.

Dominic – For guys in the trades that use tools everyday the concern of batteries being phases out isn’t as big of a deal in my opinion. By time that happens many of us are already replacing batteries that are worn out. Most of the brands at this point have stuck for very long periods to a battery platform, at least long enough so that we get our investment back on the batteries.

Excellent comparison. I do have a question. Wasn’t the Dewalt used daily for a couple of years already while the Milwaukee was brand new? I was just wondering if that had something to do with the latter’s smoother “chatter”-free performance. Motors get dirty and lose power over time, so I thought maybe that had something to do with it. I don’t own either one, but I plan on making a decision between the two. I already have both brand tools, but I am on the Dewalt battery system.

For the head-to-head both were new. We had used another sample of the DEWALT for quite some time, but the testing was both new saws.

Great review – thanks so much! Is there any difference in noise level between the two saws? Be really helpful to have real world decibel readings.

Matt – We didn’t measure the noise levels, but I’ve used both quite a bit and I’d be shocked if there is any difference. Both sound pretty much like a cordless circ saw.

I am already on a M18 platform. I have two questions:

1. Can the Milwaukee unit be adjusted to ‘tighten up’ the specs / accuracy in the areas it failed in, i.e. 45 / 90 degree, fence, blade etc.

2. Did I understand you to say that the Milwaukee can use stacked Dado blades?

Thank you .

Mike – You can make some slight adjustments, but I’ve found these small jobsite saws are really best used for framing and trim applications, certainly not shop quality miters and detailed precision trim cuts. Yes this unit can use a dado up to 3/4″ wide.

Thanks guys I am still

trying to decide which

one to choose any other

tips that might sway my

decision.

Rgds Ivor