Best 12-Volt Cordless Impact Driver

12-Colt Cordless Impact Driver – Head-To-Head Review

It’s a good time to be a tool user! The tool market is flooded with different brands of power tools competing to outdo each other to create that perfect tool for the right application. While this is a good thing, sometimes the end result is having so many options that you can question which tool is right for what you do. This Head-to-Head comparison is designed to address those concerns and to answer the question: Who has the Best 12-volt Cordless Impact Driver?

Click here for a look at our Best 18-volt Impact Driver testing.

Best 12-Volt Cordless Impact Drivers 2019

Research has shown that many 18-volt tool users also own 12-volt tools. According to the folks at Milwaukee Tool, 70% of their 18-volt tool users are also on the 12-volt platform. Generally, 12-volt impact driver tools are smaller and have less torque than an 18 volt version. It’s a fact that many of us fail to use our 18-volt impact driver to it’s fullest capacity. Having said that, 12-volt impact drivers are best used for applications such as:

- Driving self-tapping screws in metal

- Driving 3” diameter screws in wood

- Driving drywall screws

- Driving screw anchors with short embedment depth in masonry and concrete

- Driving screws in frame anchors up to 8 mm diameter in masonry and concrete

Today’s modern 12-volt impact driver will perform 80% of our daily tasks, so the question begs to be asked, why carry the extra size and weight? -Rob Robillard

12-Volt Cordless Impact Driver Line Up

This 12-volt cordless impact driver head-to-head includes 8 impact drivers from; Bosch, DEWALT, Hilti, Makita, Milwaukee, Metabo, Metabo HPT, and Ridgid.

Before presenting the testing results, its helpful to set the stage by listing all the features and specifications for comparison. All 8 of these 12-volt impact drivers are similar in size and capacity. Specific differences are listed below.

Bosch PS 42 02

Bosch PS 42 02

No Load IPM: 0-3,100

No Load RPM: 1-1,200 / 2,600

Torque: 975 in-lbs

Weight: 2.1 lbs [with battery]

Bosch PS42-02 12V ¼ in. Impact Driver

DEWALT DCF801

No Load IPM: 3,600

No Load RPM: 0-2,850

Torque: 1,450 in-lbs

Weight: 2.5 lbs

Dewalt DCF801 XTREME™ 12V 1/4 in. Impact Driver

Hilti SID 2-A

No Load IPM: 3,410

No Load RPM: 2,500

Torque: 973 in-lbs

Weight: 2.8 lbs

Hilti SID 2-A 12V ¼ in. Impact Driver

Makita DT04

No Load IPM: 3,900

No Load RPM: 0-1,30000 / 3,900

Torque: 1,200 in-lbs

Weight: 2.3 lbs

Makita DT04 12V ¼ in. Impact Driver

Metabo SSD 12 BL

No Load IPM: 4,000

No Load RPM: 0-2,500

Torque: 1,260 in-lbs

Weight: 2.7 lbs

Metabo SSD 12 BL PowerMaxx ¼” Impact Driver

Metabo HPT WH 10DFL2

No Load IPM: 3,200

No Load RPM: 2,700

Torque: 955 in-lbs

Weight: 2.4 lbs

Metabo HPT WH10DFL2 ¼ in. Impact Driver

Milwaukee 2553-20

No Load IPM: 2,553

No Load RPM: 0-1,300 / 2,400 / 3,300

Torque: 1,300 in-lbs

Weight: 2.3 lbs

Milwaukee 2353.20 M12 FUEL ¼ in. Impact Driver

Ridgid R82230

No Load IPM: 3,000

No Load RPM: 0-2,000 / 3,000

Torque: 1,100 in-lbs

Weight: 2.5 lbs

Ridgid R82230 ¼ in. Impact Driver

Best 12-Volt Cordless Impact Driver Evaluation Format

Once again our team has put some serious time and effort into our Head-to-Head evaluation to bring you the most comprehensive information available. For this evaluation several categories were used including: Performance (speed), Run-time, Torque Evaluation, Ergonomics and Price. For each of these categories the tools were ranked, the best 12-volt cordless impact driver in this article is based on all the results combined.

Features – an overall comparison of features and specifications.

Performance – The performance evaluation looked at the speed of each impact driver based on how fast it took to drive 3” Star Drive Coated Screws into 4 layers of CDX plywood. The plywood was pre-drilled ¼” by a CNC router to ensure even spacing and starting hole depth. A second speed test was used including the average speed to install five ¾ inch self-tapping screws in high hat furring channel.

Run-time– Lots of PRO’s think run-time is important. To evaluate run-time, 3” coated screws were repeatedly installed into plywood until the battery was exhausted. The comparison of run-time for each tool is based on the total number of screws installed. The final results were adjusted to account for slightly different battery pack sizes in two of the tools.

Ergonomics – Ergonomics are really important to users and an important category to consider when purchasing any power tool. In addition to traditional ergonomics, functionality was also included in this category.

Decibels –Noise matters! Every year, thousands of construction workers suffer hearing loss from excessive noise exposure on the job.

Power Test – For this test, 3/8”x 8” lag bolts were installed into three layers of 4×6 pressure treated lumber. This is an extreme test for a 12-volt impact driver, however it is a great way to show relative power (torque plus impacts).

Price – Price is always an important factor in determining which impact driver is best for a user. The current bare-tool and kit pricing found online for each of the drivers at the time of publication was used to compare each tool.

Warranty – The warranties for the tools tested are summarized below. It’s hard to rank warranties as some of the details and fine print could make or break the user’s opinion of the warranty.

12-Volt Cordless Impact Driver “Stand- Out” Features

There were a few stand-out features that affect performance and safety. While not all of the impact drivers had stand-out features, a list of some of them are included below.

LED lighting

Most cordless tools have an LED work light option, but it seems for a long time now that DEWALT has taken this work light seriously by adding 3 lights around the nose-cone, and programming this light to stay on the longest. Bosch has jumped on this 3-light placement as well.

Rubber Over-mold

While all of the tools have some sort of rubber over-mold, Metabo actually applied some on their trigger and the bottom of the battery. While you may think this seems weird, it’s actually comfortable and prevents your finger from slipping off trigger.

Speed Change Function

Four of the eight 12-v impact drivers have a speed adjustment. They are:

- DEWALT – 2 speeds

- Metabo – 2 speeds

- Makita – 2 speeds

- Milwaukee – 3 speeds

Additionally, Milwaukee’s speed change is inset slightly protecting it from bumps and damage. The DEWALT is semi-recessed and slightly protected.

Dedicated “Precision” Mode / TEK Screw Settings

Three impact drivers in the 12-V Head-to-Head have unique dedicated settings all borrowed from their respective larger 18-V brothers. However, each mode is unique to the brand and its intended application.

DEWALT Precision Drive Mode

Intended for light applications such as machine screws and cabinet hinge screws, Precision Drive Mode will act as an electric screwdriver until resistance from the screw head is felt. Once the added resistance is met, slow low torque impacts will drive the screw head flush.

Precision Drive Mode can pause the Impact Driver for one second before impacting. This protects the fastener and material surface, providing users with control during applications that require a high level of precision.

Makita Assist Mode (A-Mode)

Like the DEWALT’s Precision Drive Mode, the Makita A-mode will initially drive the fastener at low no impact speeds for added control. However once impact required resistance is met, the driver will begin to impact at low speeds and quickly accelerate to maximum high speed impacts until the fastener is completely driven. This is designed to help control long fasteners and eliminate cross threading and cam-out.

Milwaukee Self Tapping Screw Mode

The Milwaukee Self Tapping Screw mode or Mode 4, is designed to help drive small self-tapping screws in delicate applications. When depressed the tool quickly executes a controlled acceleration to 3000 rpm to prevent walking of the screw. The driver continues to drive the screw at the full 3000 RPM speed until the tool senses the screw is reaching it’s end. The driver will finish driving the fastener at a controlled 750 rpm to eliminate breaking and stripping.

We tested this mode 4 with 10-16 x ¾” self-tapping screws and averaged 9.6 seconds for 5 screws without stripping the screw. [others stripped the screws] With regard to self-tapping screws, it was the MOST precise impact driver we tested.

You may need to take these “Stand-Out” features into consideration when making your purchasing decision. Now let’s see the results of our tests.

Size and Weight Consideration

12-volt impact driver designs by nature tend to be more compact than their 18 volt brethren. As a result, they can help you work in tight quarters, such as ceilings or in tight corners.

We measured the tools without their batteries and list them here for you to compare their relative size and weight.

All of the tools fall into the 2.1 to 2.8 lb range. With regard to relative size, [W x H x L] here is a breakdown of the top three:

Thinnest Width

- Bosch / Metabo / Milwaukee [tie]

- Dewalt

- Makita

Shortest Height

- Bosch

- Hilti

- Ridgid

Shortest Length

- Dewalt

- Milwaukee

- Makita and Metabo [tie]

| TOOL | Weight [ w/0 batt] | Size [wxhxl] | Width | Height | Length |

| Bosch | 2lb 1oz | 2.1 x 5.5 x 6.25 | 2.1 | 5.5 | 6.25 |

| Dewalt | 2 lb 5 oz | 2.2 x 7.25 x 5.02 | 2.2 | 7.25 | 5.02 |

| Hilti | 2 lb 8 oz | 2.6 x 6.16 x 7 | 2.6 | 6.16 | 7 |

| Makita | 2 lb 3 oz | 2.15 x 7.25 x 5.3 | 2.15 | 7.25 | 5.3 |

| Metabo | 2 lb 7 oz | 2.1 x 7.38 x 5.3 | 2.1 | 7.38 | 5.3 |

| Metabo HPT | 2 lb 4 oz | 2.23 x 7.25 9.91 | 2.23 | 7.25 | 5.91 |

| Milwaukee | 2 lb 3 oz | 2.1 x 7 x 5.1 | 2.1 | 7 | 5.1 |

| Ridgid | 2 lb 5 oz | 6 x 6.5 x 2.25 | 2.25 | 6.5 | 6 |

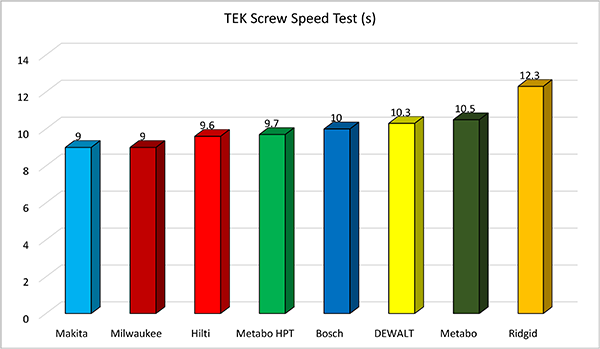

Speed Test- Installing 10-16 x 3 Self-Drilling Screw

Winner – Tied Between Makita and Milwaukee

The same operator was used to drive TEK screws into High-Hat furring channels. This test was performed multiple times to develop a 5-fastener average time.

TEK screws are commonly used in the electrical and HVAC industry. Typically, these screws are used in metal-to-metal and metal-to-wood applications. The most common are used in thin metal applications such as working with steel studs or high-hat channel, and duct work. High-hat furring channel gets its name from its hat-shape. It is a corrosion-resistant framing component used to fur out masonry walls and ceiling assemblies.

Both Makita and Milwaukee tied for the fastest time, averaging 9 seconds. Hilti came in second with an average time of 9.6 seconds, ad Metabo HPT third with 9.7 seconds.

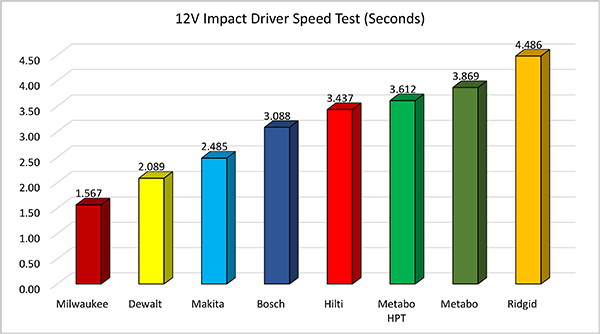

Speed – Installing 3” Star Drive Coated Screws

Winner Milwaukee

This test was performed installing 3-inch framing screws into 4 sheets of ¾” plywood. Framing screws are a common fastener on most wood framed projects.

This is a task that we feel many of our readers do on a regular basis and it highlights a task that can benefit from improved speed of installation combined with torque, resulting in productivity gains.

The drills were set on the fastest available speed, freshly charged batteries were used, and the same user did this test for all the drills to minimize any chance of time being affected by a different user. The users were swapped out and the test was done again, and all the data was averaged for all users.

The following chart shows the results of this test:

Milwaukee averaged 1.5 seconds per screw and finished in first place. It beat out a win over the DEWALT by 0.58 seconds, which finished in 2.08 seconds.

Makita came in third place with 2.48 seconds. Clearly the data shows a close race for this application and these tools are quite fast when installing 3” screws.

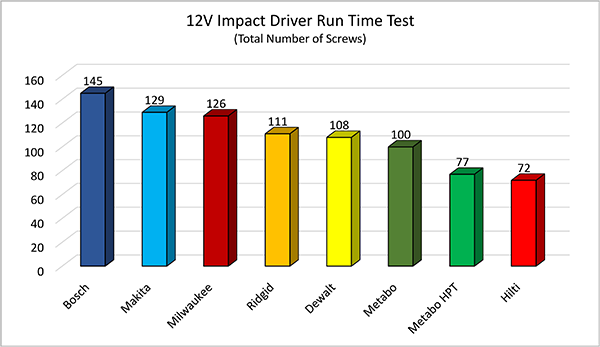

Run-time – Number of Screws Driven on a Charge

Winner Bosch

3-inch framing screws were used to determine a run-time winner. Six of the eight impact drivers tested had 2.0 Ah battery packs. Two of them didn’t have the same size packs so the results were adjusted to normalize the results based on every tool using a 2.0 Ah pack. By using watt-hour (total battery pack energy) we level the field for both voltage and amp-hours. Because all the tools are 12-volt, voltage in this case doesn’t effect the calculation like it did in our previous head-to-heads where we had varying voltages.

Watt-Hours is calculated by multiplying the voltage (actual voltage, not the MAX that some companies advertise) by the battery pack Amp-Hours. This calculation allows us to compare the total energy available to do the work based on both the voltage and size of the battery pack (amp-hours).

Bosch installed 145 fasteners and took a very comfortable first place. Second place went to Makita with 129 screws, followed closely in third place by Milwaukee with 126 screws.

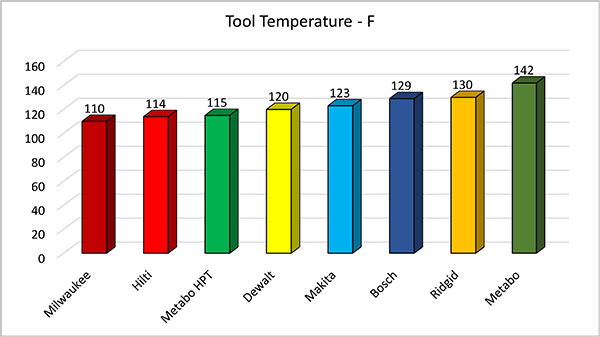

Tool Temperature

During the run-time testing it was observed that some of the tools were heating up, so at the end of the run-time test, temperature readings were taken of the tool and batteries. These results were not ranked, but listed for your information.

12-volt Cordless Impact Driver Ergonomics

Winner – DEWALT

For the ergonomics section the team evaluated the following: grip, trigger switch, battery change, forward / reverse switch, vibration, balance, maneuverability, LED, collet, and speed change function / location. For each category, the team ranked them 1, 2 or 3, (1 being the best).

The DEWALT finished in first place for ergonomics, followed by Makita in second and Bosch in third.

| NAME | Grip | Balance | FWD / REV | LED Coverage / Quality | Collet | Batt Change | Speed Changing | TOTAL | RANK |

| Bosch | 3 | 2 | 2 | 1 | 2 | 1 | 1 | 12 | 3 |

| DEWALT | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 8 | 1 |

| Hilti | 2 | 1 | 2 | 2 | 2 | 2 | 3 | 14 | 5 |

| Makita | 1 | 1 | 1 | 1 | 2 | 1 | 2 | 9 | 2 |

| Metabo | 2 | 2 | 1 | 2 | 2 | 3 | 2 | 14 | 5 |

| Metabo HPT | 1 | 1 | 3 | 3 | 2 | 1 | 3 | 14 | 5 |

| Milwaukee | 3 | 3 | 1 | 2 | 1 | 2 | 1 | 13 | 4 |

| Ridgid | 3 | 3 | 3 | 3 | 2 | 2 | 3 | 19 | 6 |

DEWALT ranked a 1 in every category except a 2 in the battery change category. Makita ranked a 1 in all categories except the collet and speed changing location. Third place went to the Bosch who excelled in the LED category, battery change and speed change button.

The DEWALT is a nicely sized tool, at 5.05 inches long and 1.75 pounds it is extremely comfortable to use.

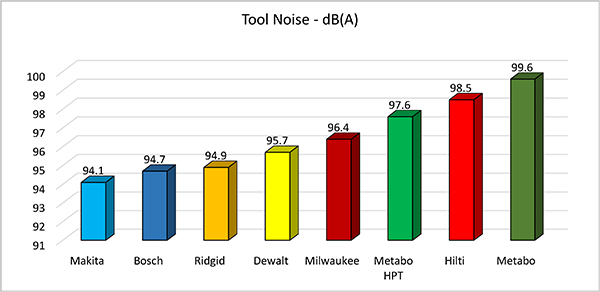

Noise (Decibels)

Winner Makita

These cordless impact drivers all measured in a range of 94.1 to 99.6 decibels. The Occupational Safety and Health Agency (OSHA) has determined safe noise levels and has made recommendations that specific ear protection devices be worn for sound levels of 85 dB or higher.

Decibel Procedure

As you know, sound measurement and reporting is a highly precise scientific process. In order to achieve an accurate decibel reading the tests need to be conducted in an an-echoic (free from echo) chamber with multiple high-precision microphones placed around the test tool.

However, these sound intensity levels will not be those that users will encounter in field conditions. Users will hear sound reflections from walls, ceilings and hard surfaces and ambient noise. Users, believe it or not, may slip or strip fasteners with the bit in their impact drivers. These factors will lead to a higher peak sound intensity.

These head-to-head tests are not performed in a testing laboratory, and it’s not the intention of this article to portray testing laboratory results. For these tests noise is measured using commercially available, high quality equipment.

The decibel levels were recorded while installing 3” deck screws into four layers of plywood. Numerous fasteners were installed to develop an average reading.

Its important for readers to focus on the relative values of these test results. Its worth nothing that ALL of these tools are loud enough to require hearing protection. So why rank them? Well it’s not just the user who’s impacted by noise, the surrounding jobsite is also affected so any improvement in noise is important. Due to the above factors, readers will note that the TBB sound test results will not track to those that the tool manufacturers publish for their tools.

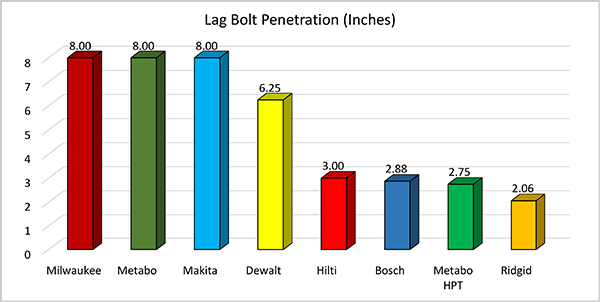

12-volt Cordless Impact Driver – Power Testing

Winner – Tie Between Milwaukee, Metabo and Makita

For the power testing we recognize that these 12-volt impact drivers are NOT designed to install large fasteners or have the capacity of an impact wrench. However, showing power as a relative comparison MAY be useful to you. Also, we recognize that many of you have used 12-volt tools to fasten nuts and bolts and smaller Timberlok fasteners.

Below are results showing how each impact driver was able to drive larger diameter fasteners thus giving readers a relative comparison of power (torque plus impacts):

For this test, 3/8”x 8” lag bolts were installed into three layers of 4×6 pressure treated lumber.

Three of the eight impacts were able to fully seat the 3/8″ x 8″ lag bolt; Milwaukee did it the fastest in 45 seconds, Metabo completed the install in 1:08 minute and the Makita did it in 1:10 minute.

The other impacts did not fare as well. The DEWALT was able to install the lag bolt 6-1/4″ out of 8-inches and the rest were between 2-3″ of penetration.

12-volt Cordless Impact Driver Price Category

Winner: Ridgid

Pricing is a key part of the purchasing mix, and it’s crucial that you get it right in order to determine the Best 12-volt Cordless Impact Driver.

There are certain considerations to make when buying power tools to get the most out of them and be able to complete the application you need it for.

For this Head-to-Head we list the bare tool and kit price [at the time of publication] for your review. We scored the tools as bare tools. Metabo HPT is the only tool that does not come as a bare tool, so we used their kit price.

| RANK | Price Bare Tool | Price Kit |

| Bosch | $120.00 | $159.99 |

| Dewalt | $99.00 | $139.00 |

| Hilti | $90.00 | $189.00 |

| Makita | $90.00 | $149.99 |

| Metabo | $129.00 | $229.00 |

| Metabo HPT | N/A | $100.00 |

| Milwaukee | $119.00 | $169.00 |

| Ridgid | $45.00 | $119.00 |

The pricing purchasing matrix is way more complicated than just the price of the tool.

Every cordless power tool, at all levels from budget-priced to super-premium, has design compromises. First, of course, is the cost. It doesn’t matter how great a power tool is, if the price is more than your budget will allow, then it can’t even be considered.

For example, if you want more speed; you sometimes have to give up torque. More torque? You might need to put up with heavier weight.

Buy Now From Our Sponsored Retailers

In order to come up with the right tool for you, you’ll need to consider all of these factors:

- Tool performance

- Torque

- Speed of application

- Features

- Size and weight

- Feel of the tool

- Cost

- Brand loyalty

- Already on the battery platform

Leave us a comment on which of these aspects are most important to you.

Warranty

Winners: RIDGID and Hilti

It’s hard to rank warranties, as some of the details and fine print could make or break the user’s opinion of the warranty. We STRONGLY suggest that you read the fine print in order to completely understand the warranty of a tool you may be purchasing.

The warranties that stand out are DEWALT, Hilti, Metabo HPT and Ridgid.

- DEWALT rounds out the list with a 1-year of free service and 3-year limited warranty, and a 90-day no questions asked return policy.

- Bosch 1-year limited warranty

- Hilti’s 2-year wear and tear at no cost to the user agreement is very nice especially with a 1-day service turn around with no-charge shipping

Hilti also offers a 20-year limited warranty! That’s four times the length of the next best competitor which is Milwaukee’s 5-year warranty.

- Makita 3-year limited warranty, 30-day refund or replace, at Makita’s option

- Metabo 3-year limited warranty tool, 3-year limited warranty on batteries and chargers, 30-day free replacement.

- Metabo HPT doesn’t offer any wear and tear warranties but does offer a lifetime (of the tool) warranty.

- Milwaukee 5-year Limited Warranty (tool only), Battery warranty depends on the model and is 2 or 3 years.

- Ridgid is the warranty king with a Lifetime Service Agreement that covers wear and tear from normal use and even batteries. Just register within 90 days and you’re good to go! Ridgid also has a 90-day return policy, 3-year limited warranty, and a Lifetime (of the original purchaser) Service Agreement.

Overall Ridgid’s LSA is definitely worth a look as is Hilti’s 20-year limited warranty, with 2-year, no cost, wear and tear coverage. Don’t forget Hilti’s excellent reputation for making highly durable professional grade tools make them worth a serious look if you want a tool that is going to be around for a while.

Overall Best 12 Volt Cordless Impact Driver – Winner: Makita

The Best 12 Volt Cordless Impact Driver goes to Makita – by a long shot. Milwaukee came second and DEWALT a distant third.

Usually our Head-To-Heads are a lot closer in scores – Makita CRUSHED the competition coming in seven points over Milwaukee. Makita came in first in two categories: TEK screw speed test, and decibel ranking. Coming in second for run-time, ergonomics and price and third for speed under load and the power testing.

Milwaukee, on the other hand, came in first in three categories: Speed under load, power test, and TEK screw speed. They have a powerful and extremely fast impact driver. What hurt Milwaukee was their third place rank in run-time, and fourth in ergonomics. Milwaukee also did not fare well in the grip and balance scores in the ergonomic section. The team all favored the thinner grip style on the impacts with the slide pack batteries, over the fatter stem pack styles. Lastly, pricing and decibels hurt Milwaukee.

1st Place: MAKITA – 2nd Place: Milwaukee – 3rd Place: Dewalt

DEWALT came in first in the ergonomics category, second in the speed under load, and fourth in the power test, decibel and price categories. The run-time test and TEK screw speed test hurt DEWALTS overall score.

| MANUFACTURER | Speed – Under Load | Run Time | Lag Bolt Test – Power | Ergonomics | Tech Screw Speed Test | Decibel dB[A] Rank | Price Rank Bare | Category Subtotals | BEST Overall Impact Driver |

| Bosch | 4 | 1 | 6 | 3 | 4 | 2 | 7 | 27 | 4 |

| DEWALT | 2 | 5 | 4 | 1 | 5 | 4 | 4 | 25 | 3 |

| Hilti | 5 | 7 | 5 | 5 | 2 | 7 | 2 | 33 | 5 |

| Makita | 3 | 2 | 3 | 2 | 1 | 1 | 2 | 14 | 1 |

| Metabo | 7 | 6 | 2 | 5 | 6 | 8 | 8 | 42 | 8 |

| Metabo HPT | 6 | 8 | 7 | 5 | 3 | 6 | 5 | 40 | 7 |

| Milwaukee | 1 | 3 | 1 | 4 | 1 | 5 | 6 | 21 | 2 |

| Ridgid | 8 | 4 | 8 | 6 | 7 | 3 | 1 | 37 | 6 |

Final Thoughts

12-volt impact drivers are the real deal now! When it comes to the Best 12-volt Cordless Impact Driver, it’s good to know that power and run-time are now sufficient for lots of tasks that we perform daily. In fact, unless you’re framing or dealing with BIG fasteners, a 12-volt impact driver may be all you need.

We get lots of comments about how we make the final rankings. As we’ve stated, there are hundreds of ways to compare tools. The good news is we’ve openly shared ALL the data from our tests, and you can rank the tools however you want.

Don’t care about an item we ranked? No problem. Simply remove that from the matrix above and re-rank them. Hopefully you’ll find this Head-To-Head useful in comparing 12-volt impact drivers.

Best 12-Volt Cordless Impact Driver Video Review

About the author

10 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Thanks Rob for the great info

Hey Rob I think I have watched all your head to head reviews and love them. I can appreciate all of the time and material you go through to run each competition, and the unbiased opinion is nice. That being said all my batteries and tools are Milwaukee and I will be with them forever. Second in this test but number 1 in my heart.

warranty puts the ridged at the top of my list while perhaps not quite the best at other things, I’ve thrown away far too many tools because of bad batterys and broken parts (a quick look into the local battery recycling box shows I’m not alone).

Hello, Robert Robillard

So happy whenever I see a new Concord Carpenter Head to Head. You guys set the bar when it comes to tool reviews. Keep up the amazing work!

It would be great to know how fast their charging system takes to recharge. It’s great when your tool can drive a lot of screws in a short time, but if you can only drive screws 30 min out of every hour, that’s not good. I believe Makita is fast charging, and I was just on Milwaukee’s site and found their M12 chargers take an hour.

Ron – Certainly can be an issue, but nearly every manufacturer now offers some sort of fast charger, and with at least one backup battery most people cannot outwork the batteries / charge times.

Thanks, Good to know. My current batteries are obviously past their shelf life, but took so long I never really noticed. My current 14.4V Rigid batteries are about 10 years old and the charger barely keeps up.

Great review. I have the Bosch 12v, and I like it a lot, but I have a hard time taking out the batteries. I see that the Dewalt and Makita have different style batteries, are these as hard to remove.

Not at all

Thanks !