Milwaukee Finish Nailer Review – Gen 2

Milwaukee M18 FUEL 15g and 16g Angled Finish Nailers

Milwaukee Gen 2 M18 FUEL 16 Gauge and 15 Gauge Finish Nailers

First Impression | Milwaukee Gen 2 Finish Nailers

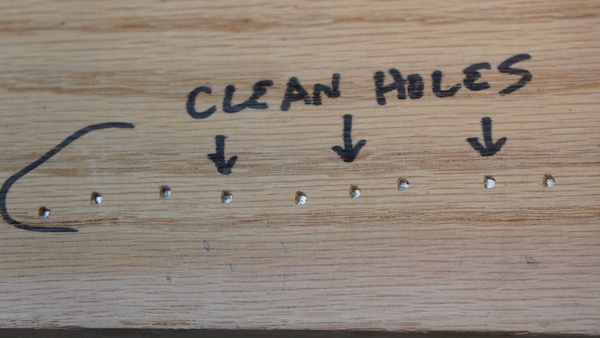

Both the M18 FUEL 16 gauge and 15-gauge, angled finish nailers install fasteners with clean, consistent nail holes. The MOST impressive thing about the nailers is how fast they install nails.

When using this nailer one BIG Difference from the earlier generations is how smooth it is. Gen 1 and Gen 2 are similar in weight, but Gen 2 was redesigned to be a more ergonomic design. The Gen 2 was narrowed to improve line-of-sight to the work surface and allow better access in tight spots. The Gen 2 has way less recoil, and most importantly, the quality of the fastener hole size has improved. There is a marked improvement [reduction] of the hole left by the nail and striker.

Full Ground Up Design

Milwaukee gave the Gen 2 16 gauge and 15-gauge M18 FUEL finish nailers a complete overhaul. Here’s what’s different:

User Feedback | Gen 1 Finish Nailers

The earlier Gen 1 finish nailers had several negative user feedback issues, that resulted in a complete “Back to The Drawing Board,” approach.

Gen 1 User Feedback

- Double-Striker mark

- Oversized holes in the material

- Bulky nose and tooltip, that inhibited sightlines

- Inconsistent toe-nailing result

- Finicky with different manufacturer nails

Milwaukee Gen 2 Finish Nailers | What’s New?

Milwaukee made significant improvements to their 15- and 16-gauge Gen 2 finish nailers:

More Power | Lower Tank PSI

The earlier Gen 1 finish nailers were powerful which resulted in too much recoil.

To address this, Milwaukee reduced the energy output [PSI in the tank] Which results in less wear and tear on the tool, less jumping off the material [smaller fastener hole], and less recoil.

The Gen 2 nailers have an inner cylinder with a nitrogen air spring mechanism [piston] and an outer cylinder. The area between the two cylinders is filled with Nitrogen to a specified PSI. Nitrogen has two primary benefits.

The biggest benefit of using pure nitrogen is that it is less permeable through seals than compressed air, which lowers the risk of pressure leaking through seals, increasing the durability/amount of nail fires before ever potentially requiring a service.

The secondary benefit, while much lesser, is less corrosion/oxidation build-up risk over time as they use pure nitrogen (99%+) versus compressed air.

Hole Size Too Big | Double Striker Mark

Feedback on the Gen 1 nail holes was way too big.

One interesting fact was that it was the dynamic movement of the tool, and the striker pin slipping off the nail head was causing the double striker mark. When Milwaukee filmed the nailer and slowed it WAY down, they discovered that the striker would drive the nail and slip off, causing a larger hole. To the naked eye, it looked like two distinct holes.

With the Gen 2 Finish Nailer’s Milwaukee did three things to improve this.

- First, they redesigned the striker (the component that drives the nail) to leave smaller holes in the material when a nail is driven.

- Second, they improved all the nail guiding and feeding components to ensure the nail is always in the proper position to be fired within the tool.

- Third, they distributed the tool weight in a way to ensure the striker was not slipping off the nail head while the nail was being driven, which was another factor that led to large holes / double striker marks with the Gen 1 nailer.

Our testing and field use showed Gen 2 to be an improvement.

Contact Bracket Improvement

On earlier testing, we found that the Gen 1 installed fasteners, 3/16th inch off-center, which we felt was the result in too much play in the contact bracket.

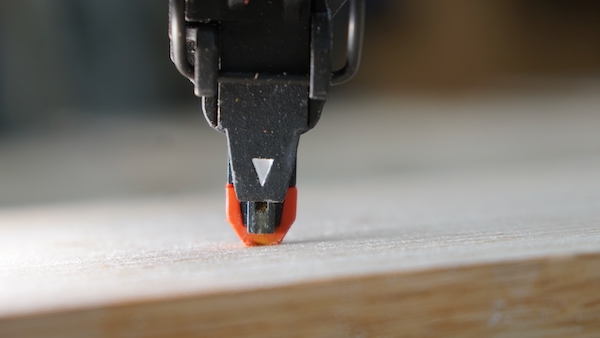

Gen 2 does not have this issue. Milwaukee changed from the wire from tip [rolled wire] to a precision point tip, resulting in WAY better line of sight, and getting the tool into narrower and tighter spots. Our testing found the contact tip accurate, by lining up the white arrow, we were able to place a nail exactly where we wanted to.

Milwaukee Gen 2 M18 Finish Nailer Specifications

M18 FUEL™ 15 Gauge Finish Nailer (2839-21CT)

- 34 Degree DA Style 15GA Finish Nails

- Nail Length: 1 ¼” – 2 ½”

- LED Work Light

- Reversible Belt Clip

- Tool-Free Jam Clearing Latch

- Three Work Contact Bracket Tips with On Tool Storage

- Tool-Free Depth Adjustment

- Bumpers & Over mold to Protect Finished Surfaces

- User Interface with Dedicated Power Button and Firing Mode Button

- Weight (w/out battery): 6.5lbs

- Warranty: 5 Years

Kit Includes: M18 FUEL™ 15 Gauge Finish Nailer, (1) M18™ REDLITHIUM™ CP 2.0Ah Battery Pack, (1) M12/M18™ Charger, and Contractor Bag

*Also available as a bare tool (2839-20)

M18 FUEL™ 16 Gauge Angled Finish Nailer (2841-21CT)

- 20 Degree 16GA Angled Finish Nails

- Nail Length: 1 ¼” – 2 ½”

- LED Work Light

- Reversible Belt Clip

- Tool-Free Jam Clearing Latch

- Three Work Contact Bracket Tips with On Tool Storage

- Tool-Free Depth Adjustment

- Bumpers & Over mold to Protect Finished Surfaces

- User Interface with Dedicated Power Button and Firing Mode Button

- Weight (w/out battery): 6.4 lbs.

- Warranty: 5 Years

Kit Includes: M18 FUEL™ 16 Gauge Angled Finish Nailer, (1) M18™ REDLITHIUM™ CP 2.0Ah Battery Pack, (1) M12/M18™ Charger, and Contractor Bag

*Also available as a bare tool (2841-20)

The Milwaukee Finish Nailer Gen 2 | Now A Little Longer

The Gen 2 finish nailers are a little longer than their predecessors. The slimming down allows the tool to get into corners and tighter spots.

Belt Hook Redesign | New Location

The Gen 1 finish nailers had Milwaukee’s standard, old M18 belt hook. Milwaukee changed the style of the hook with a larger, better flare-out. They also moved the hook from the tank location to the bottom of the tool.

As a right-handed user we think this hook is ok, not great, here’s why:

Considering that 85% of users are right-handed, mounting on the left side of the tool [for right-handed users] we found the hook is partially blocked by the magazine, which prohibits smooth and easy hooking onto your belt. Hooking onto a loose tool bag seemed fine, but to hook onto the tool belt, you must look, use a second hand, and maneuver the nailer to engage the clip onto the belt. Once hung, the nailer hangs better off the belt and is balanced.

When the hook is mounted on the right side of the tool [for left-hand users] the hook works flawlessly.

Angled Battery

The battery orientation has been angled allowing the tool to sit upright, on its battery pack and magazine.

Improved Fastener Capability | DA Style Nails

The Gen 1 nailer was designed to work with all brands of 34-degree DA nails, but the reality is that 34-degree DA style nails all differ slightly across different manufacturers.

To address this Milwaukee improved all the nail guiding and feeding components to accommodate to be less sensitive to these slightly different manufacturing tolerances.

PRO TIP:

Angled 15g finish nailers are designed to take either DA style or FN style, with DA being more significantly popular and easily found at distributors. All 16g angled finish nails are 20-degree collation angles.

FN style or DA style angled finish nails are NOT interchangeable. They have a different collation angle and head shape from one another. While the differences may seem slight, but It’s enough to jam your nailer.

- DA type of nail has a 33- or 34-degree angle and a round head. DA-style nails were created by Senco Brands,

- FN type of nail has a 25-degree angle and rectangle head. FN-style nails were originally created by Bostitch.

Read more on DA vs FN Style nails here

Read more on the differences between 15-gauge vs 16-gauge finish nailers here

Increased Runtime

Milwaukee found that by making design changes to the piston/cylinder design they could reduce the pressure in the cylinder while increasing driving power and improving nail drive depth consistency significantly. With these design changes to improve nail driving performance, there was no reduction in run time from the Gen 1 Nailers

The Gen 2 nailer magazine holds 110 nails and is able to accommodate DA fastener sizes from 1-1/2 to 2-1/2” When paired with a 2.0 Ah battery these nailers will install

- 15-gauge: 750 nails per charge

- 16-gauge: 800 nails per charge

Thermal Overload Protection

Milwaukee made some big improvements from Gen 1 to Gen 2 regarding thermal protection controls. Gen 1 would hit thermal protection at approximately 100-150 nails when fired at a fast rate continuously.

The Gen 2 Finish Nailers can fire 350-750+ nails continuously depending on how fast you’re firing. Job site users should never find themselves hitting a thermal protection limit with the Gen 2 tools, whereas that was possible with Gen 1.

While speed may be fun to talk about and interest some production trim carpenters, the real test on the job site is the fastener holes, depth of fastener, line of sight, accuracy, and doing quality work.

User Interface

The power switch and mode button are now inline resulting in a cleaner look and easier to access/use.

This power button still needs to be pressed for approximately 2-seconds to power on the tool. The Gen 1 tool requires you to hold the power switch button down for 5-7 seconds to turn off the tool. With Gen 2, turning the unit off requires depressing the switch for 2-seconds. Which is WAY better!

Note: The tool will power itself off after 60 minutes (1 hour) of inactivity. This is to ensure the tool is safe if left unattended on a job site, or if it is accidentally stored in your vehicle/storage box.

A green power indicator light illuminates the entire time the tool is powered on, and connected to the battery.

Milwaukee Finish Nailer | Gen 2 Performance

Let’s talk about our experience using these nailers. We found both the 16-gauge and 15-gauge, angled finish nailers installed finish nails consistently, at the desired set depth.

Throughout our testing, the nailer performed flawlessly with no jams or misfired nails.

The crew loved that there is no “ramp-up time” for this nailer, meaning that the tool does not pause to recharge itself – it placed a nail as fast as we were able to accurately aim, set, and pull the trigger. The recoil is smoother too.

In the field, we used the nailers mostly with PVC trim. In the shop, we tested the nailer by fastening different wood species from Oak, Poplar, and plywood. We evaluated:

- Speed

- Fastener penetration

- Nail hole-size

- Depth adjustment

- Toenailing

- Magazine loading

- LED light

The results were the same as in the field – we experienced consistent depth, fast fastening, and no nail jams. There was no issue with toenailing and the nailer was powerful to toenail into the Oak as well.

Milwaukee took their time re-designing this nailer and it shows. These finish nailers consistently performed like a pneumatic nailer by driving nails to the proper depth in Oak while leaving clean nail holes matching the head of the nail.

Clearing Jambs – Tool Free

We didn’t experience any jams in our testing. Clearing jams is a simple and easy task by unlatching the “jam latch,” clip on top of the tool nose area.

LED Light

The LED light will turn on with a trigger pull without the contact bracket engaged, giving you the ability to light your work area before you’ve placed the nose of the tool down and are getting ready to fire.

The LED light is located on the right side of the tool and is bright, but casts a shadow on the left side. As a right-handed user, this is the side I view mostly. Unfortunately, there is little to no space, on the left side for an LED light.

Power Actuation Setting

This finish nailer will operate in single sequential actuation, as well as contact [bump fire] actuation.

Milwaukee claims this nailer will fire 3-4 nails per second. We fired this nailer both in single sequential actuation and contact actuation and were impressed with the speed at which you’re able to install fasteners.

Once powered on, the actuation selector switch light [user interface] stays on the entire time the tool is on.

The indicator light tells you which mode the tool is set on:

- Continuous solid green for single sequential actuation,

- Continuous flashing green for contact actuation operation.

Depth Adjustment

The depth adjustment is easy to operate and dial in.

Dry fire Lock Out

When the nailer reaches 4-5 fasteners the contact tip will not depress indicating fastener reloading is necessary.

Weight and Balance

The M18 FUEL 15 gauge finish nailer weighs (w/out battery): 6.5lbs and the 16-gauge nailer weighs 6.4 lbs., w/out battery. Certainly not what I’d call light but not super heavy either.

Cost

The Milwaukee Gen 2 M18 FUEL 15 Gauge Finish Nailer (2839-21CT) sells online as a kit for $399. The Milwaukee M18 FUEL™ 16 Gauge Angled Finish Nailer (2841-21CT) sells online as a kit for $ 399.

Milwaukee Milwaukee Gen 2 M18 FUEL 16 Gauge and 15 Gauge Finish Nailers

Buy Now From Our Sponsored Retailers

Overall Thoughts | Gen 2 Milwaukee Finish Nailer

Having a battery-operated finish nailer that performs as well as a pneumatic nailer makes sense for many reasons. Not having to worry about setting up a compressor, hose, or gas cartridge expirations, fuel levels or cartridge cost is a win.

The most impressive feature of these finish nailers is the rate of fastening that is achieved with zero ramp-up time. I was able to install accurate fasteners into Oak at a decent rate of work with no disruption in my work speed.

To follow in the footsteps of the most interesting man in the world, I don’t always drive finish nails into Oak, but when I do, I prefer to use the Gen 2 Milwaukee nailer!

About the author

3 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Thanks for another very helpful review, Rob.

I’m wondering how the Milwaukee Gen-2s would fare:

1) thru mahogany 1-by and into the jack stud.

2) thru mahogany brickmold and into mahogany 1-by.

3) thru mahogany brickmold or 1-by and into mahogany door-jamb.

Those are the daily scenarios (listed easiest to hardest) wherein my 18v Metabo HPTs won’t consistently counter-sink.

I tested it thru 5.4 mahog into a 2×4 and it did fine, so I’m sure brickmold is similar. I did not test mahogany into mahogany – sorry – that’s some tough nailing!

It sure is.

Thanks for taking the time.

All the best.