Milwaukee 1-1/2 in. Magnetic Drill Review

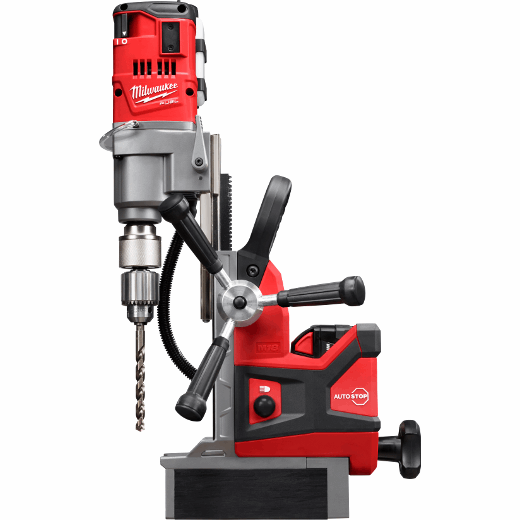

Milwaukee M18 FUEL™ 1-1/2 in. Magnetic Drill Kit (Model 2787-22HD)

Milwaukee M18 FUEL™ 1-1/2 in. Magnetic Drill Kit

Features and Specifications | Milwaukee 1-1/2 in. Magnetic Drill

Features:

- Brushless Motor w/ 2-speed settings

- Battery & Motor Overload protection via REDLINK PLUS™

- Self-Powered Magnet Base Operates Independently of Power Source

- All-metal chuck is Compatible with both Annular Cutter and Standard Drill Bits

- Integrated LED light

- Magnetic & removable lubrication tank

- Reversible and quick-release handle mounts on either side

Specifications:

- Motor: 18V, Brushless

- 2 Speed Gear Box: 400/690 RPM

- Magnetic Base Hold Force: up to 2,000 lbs.

- Stroke Length: 5-3/ in.

- Motor Head Adjustment: 5-1/8 in.

- Max Cutter Diameter (Annular): 1 1/2 in.

- Max Bit Diameter (Standard): 1/2 in.

- Size (LxWxH)(in.): 13.8 x 7.5 x 15.5

- Tool body weight: 30.9 lbs.

Power & Performance

Torque and Motor Performance

Some fabricators or iron workers may be hesitant to go cordless on a Magdrill. We get it. But the 2787-22HD Magdrill performed as well as any 110V Magdrill we’ve used. And the ease of taking it anywhere in the shop or on site without having to reposition extension cords was a godsend. We appreciated that the motor settings were labeled by drill bit type vs. 1/2. This makes it very user friendly for any fabricator or iron worker to operate.

By including a higher torque/lower RPM setting for the annular cutter bits, it also keeps the overall friction heat lower helping to extend bit life. The bottom line is that the motor setting and design work exceptionally well. And with an included 8.0Ah battery, we cut at least 60 total 13/16 in. holes on a single battery (Specs say 66) charge with a bar left when we swapped out. The holes had crisp edges and were virtually burr-free.

Drilling Depth Capacity

This Milwaukee 1-1/2 in. Magnetic Drill (model 2787-22HD) has a very impressive overall drill depth/stroke length. And it achieves it via two ways. The first is the standard rack and pinion movement engaged by the side handle. This allows for 5 3/4 in. of total up and down movement. It proved sufficient for all the drilling tasks we completed in the fab shop. Additionally, the entire motor head can be repositioned on the body rack mount. This allows for an extra 5 1/8 in. of adjustability. It’s easily done with a side toggle lever when needed. Typically the bit length was a bigger factor than the motor head movement for drilling depth limitations though. And Milwaukee’s 2-inch long, 9-piece set (model 49-22-8410), was plenty long enough for all our commercial and industrial tasks.

Magnetic Base Design

The magnetic base, as required, is extremely secure. Importantly, it is absolutely strong enough to allow the drill to be securely used for vertical or overhead drilling if you must. We found the clamp down force to be comparable to other 110V plug in Magdrills that we’ve frequently used in the Fabshop. The magnet is operated by rotating a knob at the back base of the 2787-22HD Magdrill once you’ve aligned it in the right spot. There are Pros and Cons to ANY unpowered Magnetic base, such as Milwaukee uses on the 2787-22HD.

Pros

Pros include: extending battery life and less risk of defect/malfunction. By not using the battery to power the magnet there is less overall power drawn from the battery. This means a single battery lasts longer because it is solely dedicated to powering drilling action. By having fewer circuits and electronics integrated into the tool there is also inherently less internal electronic that can malfunction.

Cons

Cons include: Tool movement when operating, non-level difficulty operating, and metal shaving cleanup challenges. You have to turn a knob with stiff resistance, so the tool can “walk” out of place. This happened a couple times during use. Once we got used to the tool design and knob resistance it wasn’t a big deal. It would be a big deal to hold this heavy Magdrill (30+ lbs) in any vertical or overhead position while having another person turn the knob to secure the magnet. Milwaukee did design it so an included strap can be used to hold it in place but the process is cumbersome. Lastly, because there is always a strong magnetic force present in the base, metal shavings always stick to it. It can be a pain to have to wipe them off to get the Magdrill to sit flat on the worksurface.

Bit Loading and Options

There are 2 options for bits for this Magdrill. And both options are included in the kit! The quick load chuck that is permanently installed is fitted for a 3/4 in. Weldon Shank. We love the keyless bit loading. You just have to twist the collar a half turn, and the bits are securely in place! It’s one less thing to lose in the fab shop or on the job site. And the firm tension gave us zero doubt that the bits would stay locked into the chuck regardless of position or jostling.

If you want to use standard round (or hex shaft) bits, then you can mount a 1/2 in. shank accessory as well. This versatility is ideal since this we always like to get as much use out of a high-price tool as possible. It also allows for the option of drill into materials other than metal for mixed material projects, like steel connector plates joining timber beams.

Key Design & Ergonomic Features

The Quick-Release Handle

We appreciate design features that make a tool comfortable for both right or left-handed operators. Milwaukee nailed this challenge in the way that they designed the quick release handle on their 2787-22HD Magdrill. There is a push button release (like the release button on a socket driver) in the center of the handle’s hub. It works great and takes seconds to release and reinstall.

Magnetic Lubrication Tank

While not essential, an ability to use lubricating cutting fluid while drill is extremely effective at extending average drill bit life. In addition, it helps to keep the material temperature lower by decreasing heat buildup caused by friction. The magnetically attached cooling reservoir tank on the 2787-22HD Magdrill is a nice feature. it’s also easy to remove or reposition on either side which is a plus. But… because it is magnetic it can also be knocked free pretty easily. That said there is a metal band around the tank and an on/off spigot so it’s unlikely to break or spill much. The drill can be operated without the tank though, so this is a minor consideration. Also, the tank can be mounted on either side to work on the opposite side of the ambidextrous quick-release handle.

REDLINK Overload Protection

The Milwaukee 1-1/2 in. Magnetic Drill (model 2787-22HD) has REDLINK Plus, which is an electronic feature that allows the tool to talk to the battery to deliver the most power. It also has the added feature of recognizing when the power draw from the battery to the motor exceeds recommended limits and can shut down the tool to protect the critical electronics. When would this happen? When you overload the system by trying to drill too fast; especially in a harder material like stainless steel. After investing this much money in a tool, this is a critical feature to extend the tool life!

Emergency Stop Considerations

As you well know by now, we emphasize safety at Tool Box Buzz. There are 2 additional safety features worth highlighting on the 2787-22HD Magdrill. First, the integrated auto-stop feature means that the bits stops almost immediately when the switch is turned off. There is a built-in electronic brake system to stop the chuck from turning. Second, the off switch is well-designed to “slap off” in an emergency. To turn it off you simply smack the paddle switch off. This means that if clothing gets snagged in the bit, you can easily shut off the drill to prevent (or limit) injury. We like that!

Milwaukee Annular Cutter Bits | Model 49-22-8410

Milwaukee sent along a 9-piece annular cutter bit set (Model 49-22-8410) for us to use with the 2787-22HD Magdrill. The HSS bits were top notch and definitely deserved their own section. We cut a few dozen holes with them with zero issues. The hole edges were clean and burr free. The bits performed with zero hang-ups and plugs came out easily. But most importantly, none of the bits shattered.

- Bit Sizes: 1/2″, 9/16″, 5/8″, 11/16″, 3/4″, 13/16″, 7/8″, 15/16″ and 1-1/16″ cutters, two 2″ pilot centering pins

Milwaukee has a proprietary HSS design that features three different “zones of hardness” in each bit. Why? The decrease the chances of the bit breaking. The harder the HSS material the more brittle it is. Having zones of varying hardness means you can have a balance between harder cutting tips/edges for extended life and softer flute and shaft areas to absorb twisting forces and decrease chances of breakage. These are high quality bits!

The bits feature common bolt hole sizing and increase by 1/16 in. steps as listed above. This allows you to use a bit 1/16 in. larger than the connection bolt diameter; a construction industry standard. The case is decent at best. The bots tend to move around inside it. It’s fine if you’re using the Magdrill in a fab shop. But if you plan to bring your Magdrill on site, then consider more secure and protective storage options.

Final Thoughts | Milwaukee 1-1/2 in. Magnetic Drill

Milwaukee’s 1-1/2 in. Magnetic Drill (2787-22HD) is a powerhouse belonging in any steel fab shop. It has awesome performance & versatility! The magnetic base is immovably strong. The rack and pinion-based handle system makes it easy to apply consistent force to drill through soft and hard metals alike. And we were impressed with the quick bit change system. It kept the annular cutter bits firmly in place and was easy to change bits even with work gloves on. The lubricant tank also worked well although the magnetic attachment makes it possible to knock loose when cutting if you aren’t careful. At $2630, this is a high-end investment. But overall, this cordless tool performed flawlessly (and just as well as the corded versions we use) and should be a no brainer if you are looking for a mag drill upgrade!

Milwaukee Milwaukee M18 FUEL™ 1-1/2 in. Magnetic Drill Kit

Buy Now From Our Sponsored Retailers

Also Available From

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.