HILTI 22v Tower Light Review

HILTI SL 10 22 Area Tower Light Review

Commercial job sites are benefitting from the cordless revolution. The hallways, corridors, and workspaces are no longer strewn with extension cords and dependent upon ‘temp power.’ The HILTI 22v Tower Light is a new entrant into the construction lighting field, joining Milwaukee, DEWALT, Ryobi, Makita, and others with tower lighting solutions.

The HILTI 22v Tower Light is part of the Hilti Nuron 22volt battery platform. We were anxious about how this light tower stacks up in the field.

Commercial builders work in spaces without permanent power lighting during the early production of finished spaces. This is because the permanent lighting depends on the trade rough-in and final inspections before those systems can operate. As a result, we know the right temporary lighting is essential to ensuring that we can work safely and effectively.

HILTI 22v Tower Light

The new HILTI 22v Tower Light configuration came with the following components

- The Area Light Tower SL 10-22 (#2374181)-

- Two (2) B22 255 Nuron Batteries (#2345534)

- Charger C 6-22 115v (#2260054)

HILTI 22v Tower Light – Specifications and Features

HILTI SL 10 22 Area Light Tower

| Power Sources | HILTI Nuron Batteries or 120v ac |

| Weight Bare Tool | 20.8 # |

| Weight with B 22 255 Battery | 24.5 # |

| Tool Height Collapsed | 45 in / 1143 mm |

| Tool Height Fully Extended | 82 in / 2083 mm |

| Dimming Levels | Three Levels |

| Light Spread | 360 or 180-degree settings |

| Ingress Protection Code | IP55 |

For readers curious about its IP55 rating, the HILTI 22v Tower Light is dust-protected at a level that some dust might penetrate the equipment but will not interfere with the safe operation of the light. For liquid, the Area Tower Light can be sprayed with a ¼” water nozzle against the enclosure at any angle and will not have any harmful operational effects.

A Unique Light Design

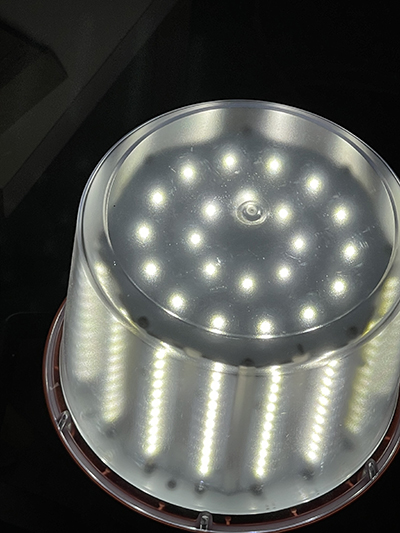

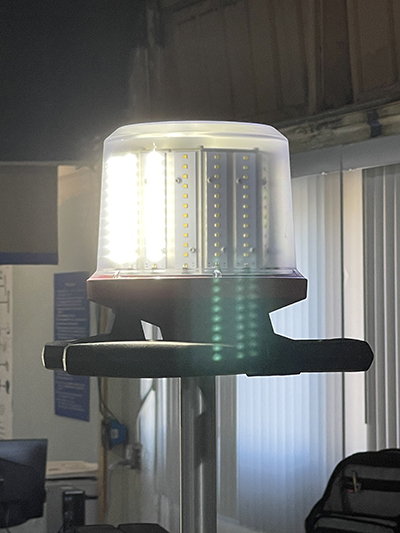

The HILTI 22v Tower Light has a unique design for the lighting head. Many other light towers have LED panels that need to be aimed or a large reflector head that casts light in one direction. The HILTI L22 has a configuration containing 16 vertical LED strips along the circumference of the head. Each of these strips has 11 LEDs. In addition, the top of the light head has an additional pattern of LEDs. That way, the tower casts a true 360 degrees of uninterrupted light.

We took the SL10-22 to our commercial job site to see how well the Tower Light performed. The results were very impressive. The light pattern inside of the interior dark rooms was bright and seamless. In particular, the drywall trades were interested in the Tower Light for their taping and finishing. The light, when adjusted to its highest position, is out of the workers’ eyes, and one cannot tell any difference in intensity when looking at the pattern on the inside of a space with white walls. That type of space would be the place that would show any such lighting patterns.

In addition to the unique light head design, HILTI can shut off half of the light head pattern to only shine for 180 degrees of the perimeter. This allows for more controlled light patterns and doubles the battery life.

Adjustability

The HILTI SL22 light head is attached to a telescoping aluminum shaft controlled by two cam levers that allow you to choose your operating height. The cam levers are easy to use and provide fast and efficient height adjustment.

Another unique feature of the HILTI SL 22 is the extension height of the head above the floor. The full extension of the head is 6 feet 10 inches above the floor. This way, the light pattern is above most users’ eye level, allowing the light tower to be outside the focal point. That is a great feature when the user’s eyes are not overwhelmed by the light.

Light Output and Run-time

The light tower has three light output modes [low-medium-high] that put out 6,500 lumens at the highest setting. When paired with the HILTI B 22-255 Li-ion battery, I experienced a run-time of:

- High Setting – 5.5 hours, illuminating both halves of the fixture.

- Medium Setting – 8.5 hours illuminating both halves of the fixture.

- Low Setting – 11 hours illuminating both halves of the fixture.

We liked the ability to go through an entire 8-hour shift using one B 22-255 battery when using one-half of the fixture. With the entire fixture illuminated, the user will need at least one change of batteries during a shift. While we only used this light with the illumination on high and were pleased with the light output, we’d prefer an 8-hour run-time to avoid changing batteries mid-workday.

Corded or Cordless? – It’s your choice

The HILTI SL10-22 Light Tower can operate on either the DC batteries or by hooking up a 120v AC cord. The AC connector is behind a black service door at the unit’s base. While running on AC power, the Light Tower does not charge the battery. That is a feature we have seen on other manufacturers’ tower lights, and it would certainly be a great future feature for the SL 10-22.

Storage and Set-Up and Adjustability

We found that you can set the light up in seconds. You can extend the multi-directional light-head from 40” to 82”. The unit weighs 20.8 lbs. It is not terribly heavy but takes up a 46” height x 11” width x 11” depth of storage space in the back of your pickup bed or trailer.

The SL 10-22 comes with a convenient carrying strap, and it is well-balanced to carry around.

HILTI SL 10-22 Price and Value

When you compare the HILTI Light Tower to other job site lighting solutions, it’s expensive, but I always consider tool purchases an investment.

We used to use Halogen lights for construction. I don’t even compare this ED Light Tower to an old-style Halogen light. Halogen work lights are outdated, they are cheaply made, and they don’t last; they run extremely hot, creating a fire hazard, and the bulbs break easily and are expensive to replace.

Today, there are a lot of cheap LED tripod options that typically sell on Amazon that cost $100 – $200 and put out 1000-2000 Lumens. I’ve used these lights, they need electric power to operate, and the first thing to break is the tripod stand and adjustment knobs. Within a year or two, one or both LEDs dim or stop working, indicating cheaper quality LEDs. High-quality LED temporary construction lighting solutions are supposed to be durable and last years and years.

The HILTI Light Tower costs 5 times or more than the cheap lights. But I put the comparison in the category of “you get what you pay for.” In the image, above, the temporary light in the corridor is a permanent light fixture that needs to be relocated and wired into a junction box every time you need the light repositioned. That is one very expensive way to provide light. But this is a common current practice. It costs nothing to relocate the HILTI Tower Light.

You get superior quality, significantly improved portability with the cordless options, better constructed LED diodes, a more durable, stable tripod platform, corded and cordless power options, and fast stow-able portability. Given reasonable care, this HILTI Light Tower should easily last you 8-10 years. When you amortize its cost over ten years, that’s a $120 per year investment.

The HILTI SL 10-22 Light/ Tower sells the way you buy it with an ala carte pricing structure. In my case, I got my system with the following components.”

- SL 10-22 Light Tower $ 548.00

- B 22 255 Batteries (2) $ 255.00 (ea.)

- C 6-22 115v Charger $ 128.00

Conclusion

We now look differently at LED job site lighting. What was once a luxury is now a necessity. LED lighting is a new industry standard for a good reason. It offers increased portability, functionality, and overall performance. And who doesn’t want improved job site safety while increasing overall efficiency and quality from vastly improved visibility.

About the author

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.