Best 18 Gauge Cordless Brad Nailer

Who Has The Best 18 Gauge Cordless Brad Nailer?

In the last couple of years many manufacturers have introduced battery powered, cordless finish nailers. With a battery powered nailer, there’s no need to worry about using a compressor or dragging round an air hose while you work. They’re ideal for climbing ladders or locations with limited power. The tradeoff is that cordless nailers weigh a bit more than their pneumatic counterparts, due to the weight of the motor and battery. While some may find this annoying at first, many users prefer the extra weight to carrying around an air compressor, plugging it in, and dragging around a hose.

18 Gauge Cordless Brad Nailer Head-to-Head Test

Four major brand 18-gauge cordless brad nailers, were reviewed and tested, to bring you the Best 18 Gauge Cordless Brad Nailer. The list of cordless brad nailers included the following:

DEWALT DCN680 18 Gauge Cordless Brad Nailer

- Tool-free jam release

- Belt Hook

- Brushless Motor

- Tool-free depth adjustment

- Two LED lights

- Low nail lockout prevents dry-firing

- Stall release lever will reset driver blade in the event of a stall

- 110 nail capacity

- ⅝” to 2-⅛” fastener length

- Height 11-⅞ ”

- Length 10-⅜ ”

- Width 3-¾ ”

- Weight 5 lbs 2 oz [without battery]

Makita XNB01 18 Gauge Cordless Brad Nailer

- Belt Hook

- Tool-free depth adjustment

- LED light

- Anti-dry fire mechanism prevents workpiece damage

- 100 nail capacity

- ⅝” to 2” fastener length

- Height 12-½ ”

- Length 11-⅝ ”

- Width 3-3/16 ”

- Weight 6 lbs 6.8 oz [without battery]

Metabo HPT NT 1850DE 18 Gauge Cordless Brad Nailer

- Tool-free jam release

- Belt Hook

- Tool-free depth adjustment

- LED light

- No dry-fire lockout

- 100 nail capacity

- ⅝” to 2” fastener length

- Height 12-¾ ”

- Length 11-¾ ”

- Width 4-¼ ”

- Weight 6 lbs 9.8 oz [without battery]

Milwaukee 2746-2 18 Gauge Cordless Brad Nailer

- Tool-free jam release

- Belt Hook

- Tool-free depth adjustment

- LED light

- Low nail dry-fire lockout

- 110 nail capacity

- ⅝” to 2-⅛ “ fastener length

- Height 10-3/16 ”

- Length 11-⅞ ”

- Width 3-5/16 ”

- Weight 5 lbs 7 oz [without battery]

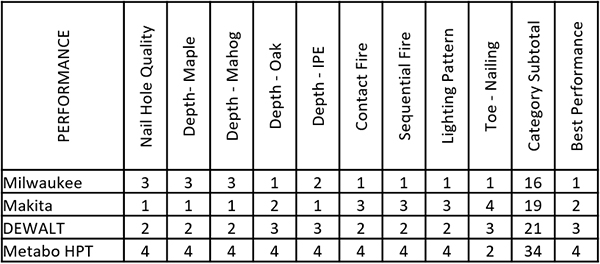

Best 18 Gauge Cordless Brad Nailer Comparison Testing

Several test simulations were used which are considered typical of tasks where a carpenter might use a brad nailer on. The simulations included:

- Soft Wood Trim Installation– Brad nailers were used to install Pine trim onto framing lumber, to evaluate hole quality.

- Hard Wood Trim Installation– Brad nailers were used to install Oak, Mahogany, IPE and Maple trim over plywood. This test allowed us to evaluate power, penetration of fasteners, depth of drive adjustments and nail hole quality.

- Toe-Nail Application– We installed ½” Poplar bead-board was installed onto framing lumber by toe-nailing the tongue of the trim. This test evaluated penetration of fasteners, line of sight, and depth of drive adjustments.

- Line of Sight and Accuracy Testing – Fasteners were installed onto cross-hair marks, and straight lines, to determine how well users could hit the marks and determine line of sight and accuracy of the contact tips.

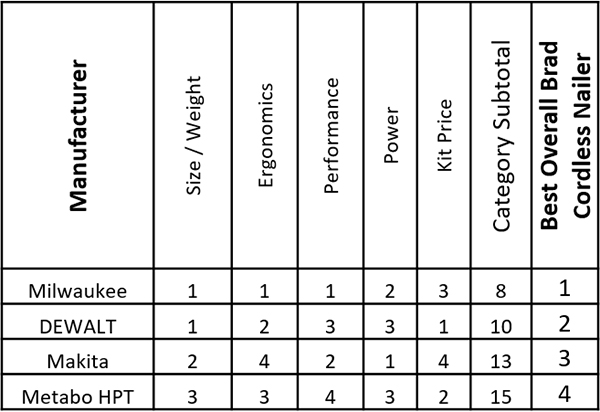

18 Gauge Cordless Brad Nailer – Factors Considered

In addition to the simulations each of the crew members spent time shooting fasteners into varying materials, to evaluate each brad nailer independently. The simulations and individual evaluations were used to determine the Best 18 Gauge Cordless Brad Nailer, in several categories including:

- Size and Weight

- Ergonomics

- Features -Performance

- Power

- Price

- Best in Class – derived from the above categories

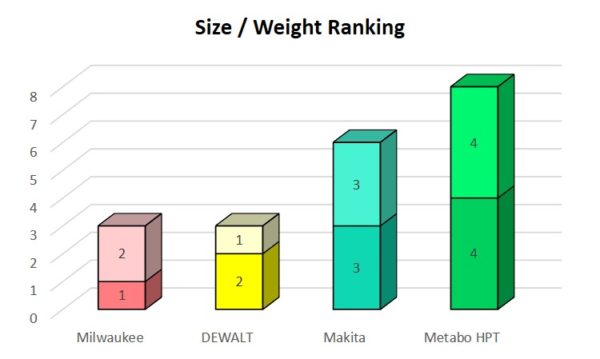

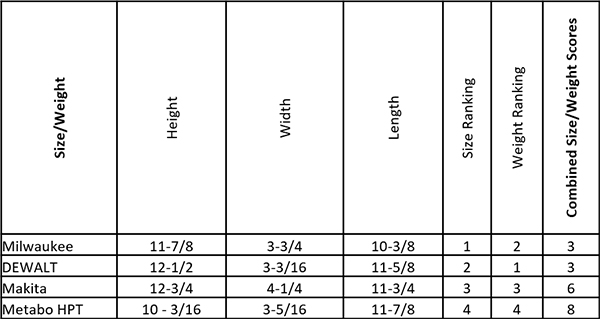

Size and Weight – WINNERS – DEWALT and Milwaukee

Cordless brad nailers certainly benefit from the lack of an air hose, but have to compromise due to added weight of batteries.

The length, width, and height of the nailers were used to determine their cubic volume, and a rank was assigned based on volume and tool weight. In the accompanying graph, the upper band is the weight of the nailer while the lower band is the size ranking of the nailers.

The lightest brad nailer was DEWALT , at 5.2lbs. followed very closely by the Milwaukee at 5.7lbs. Makita and Metabo HPT were the heaviest brad nailers, approximately 1lb. heavier than DEWALT and Milwaukee.

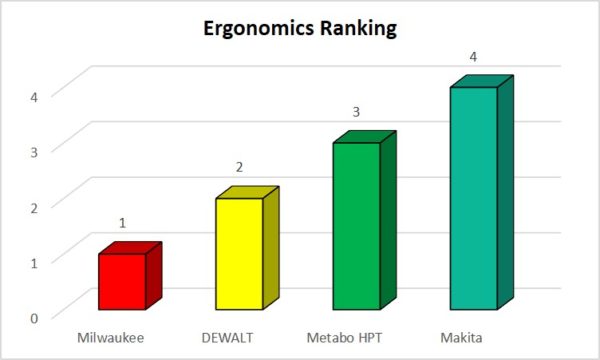

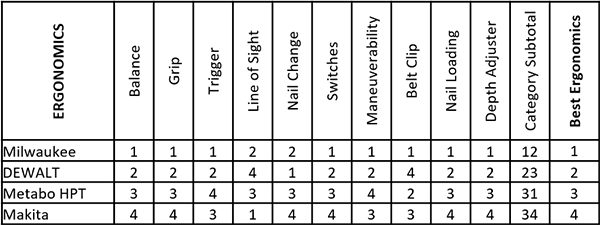

Best Cordless Brad Nailer – Ergonomics – WINNER – Milwaukee

Ergonomics play a major role in all of our evaluations and testing. Not only does a tool need to perform well, but it’s very important that tools are comfortable, which ultimately leads to more productivity and reduced risk of injury.

Milwaukee finished first for the ergonomics category, coming in 11 points better than the second place DEWALT and 21 points better than the third place Metabo HPT. The team felt that the changes made to the NEW Milwaukee Gen 2 nailer were noticeable and impressive.

Balance

The team felt that Milwaukee was the best balanced nailer, with an even weight distribution

“The weight distribution of this M18 nailer is great!” ~ Ethan Bickford

The DEWALT is more top heavy [with 2.0 Ah battery] but that can be drastically improved, by installing a heavier 5.0 ah battery. In that configuration, DEWALT was as evenly balanced as the Milwaukee, but, slightly heavier.

Trigger Switch

The Milwaukee switch is a “hinged switch to mimic the action of a pneumatic brad nailer. It is also spring-loaded, has more resistance than the others and has a smooth action. DEWALT is a slide switch, [similar to their drills] with spring, and NOT as strong as the Milwaukee. The others are all slide action triggers.

Functionality Switches

DEWALT switches are spread out over the tool and are all mechanical switches, meaning that they are positive on or off. The benefit to this is that it’s easy to operate, quick to activate, and really intuitive.

Milwaukee uses push-button, electronic switches, which are smooth, quick to use, and intuitive. The Milwaukee switches are all in one place, and protected under the handle. They also require that you push and hold for two-seconds, which ensure that you avoid a bump or change by accident.

Metabo HPT and Makita have “chintzy” trigger slide-locks. The Makita nailing mode switch is a rocker type, and protected by a dust boot.

Maneuverability

The Milwaukee and DEWALT have the easiest maneuverability and that is related to their weight and evenly distributed balance.

Belt Clips

Milwaukee is the easiest clip to hook on, and its hook has a slight outward curve which assists by sliding over, and onto a belt. All of the nailers hung the same, [straight down] once clipped on a belt.

Milwaukee and DEWALT use a wire-style clip, the DEWALT thinner than Milwaukee. Makita is a thin metal plate style, with a low profile, but it was harder to hook on belt.

Metabo HPT has a 1-1/2” wide, massive belt clips, which resembles more a rafter hook, [see photo] than a belt clip. The team felt that it was a bit “goofy” for a trim carpenter. Functionally speaking, it simply sticks out too far.

Loading Nails

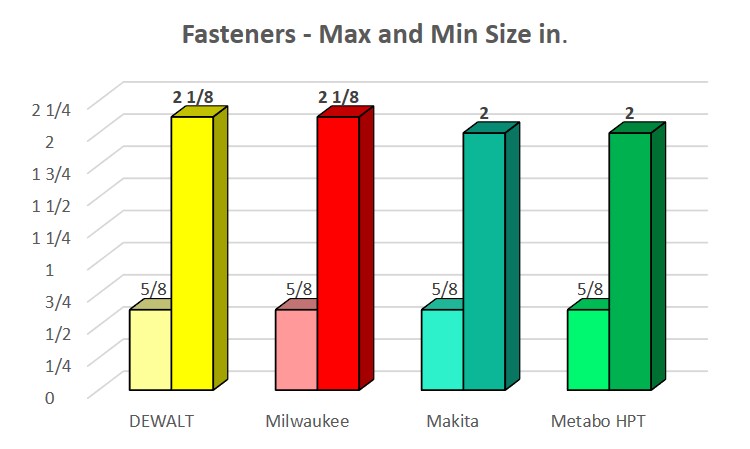

The DEWALT and Milwaukee both hold 110 brad nails, and are the only nailers that can drive up to 2-1/8 brad nails. The Makita and Metabo HPT have a maximum capacity of 100 brad nails and are limited to a 2-inch nail length.

The DEWALT and Milwaukee were the easiest two nailers to load nail strips of nails into.

The team noticed that when loading a full strip of 2-inch brad nails in the Makita nailer, the tab at the upper magazine housing prohibits the nail strip from tilting in. In order to get a full strip in, users have to lift the strip from the bottom and roll it in. While this is not a fatal error, it does go against how many users load nail strips.

Depth of Drive

All of the brad nailers that were reviewed have an adjustable depth of drive.

Milwaukee has a large, easily adjusted knob with a positive clicking action. The range of adjustment is spread over 26 clicks. DEWALT has a recessed knob, with visual arrow indicator and has 7 clicks for its full adjustment range.

Metabo HPT has a knob that turns 11 times, but you can un-screw it too much and disconnect the contact point. Setting the depth of drive was easy, and very responsive.

Makita’s depth of drive knob, has 4 turns to its rotation range, and if turned too much one way, the knob jambs tight. We found the Makita depth of drive, extremely hard to navigate, but once dialed in [sweet spot], it produced the BEST looking nail holes.

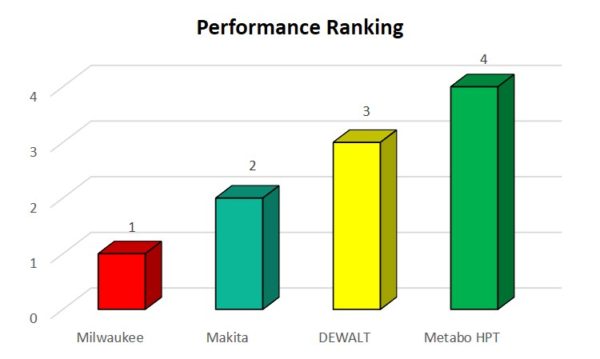

Performance – WINNER Milwaukee

This category reflects the overall impression that the tool delivered while driving fasteners in each of the test setups, along with the individual team member evaluations. For this valuation, performance was defined as the ability to consistently drive fasteners, to the correct depth, at a pace the user would use, to install trim, as compared to a pneumatic nailer.

Toe-Nailing

All of the nailers are able to toe-nail well. The Milwaukee, with its narrow tip attached, was the MOST accurate, and easiest to use and place an angled fastener. The Metabo HPT tip once depressed, was very accurate in brad placement in the tongue and groove nailing. While the Makita’s narrow tip is easily viewed, on straight nailing, when held at an angle the nail shot further than anticipated.

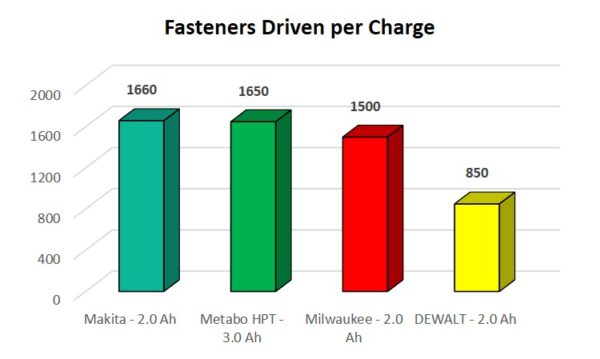

Run-Time

While run-time is important with cutting, grinding and impact tools, it’s really less of a factor on brad nailers. Most nailers come with smaller batteries which keeps it weight down. Three of the four brad nailers can use a 2.0 Ah battery. Metabo HPT offers a 1.5 or a 3.0 ah battery. The following chart shows manufacturer’s reported run-times:

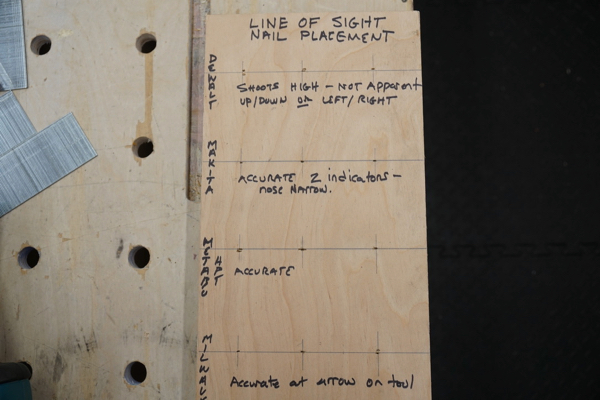

Line of Sight – Accuracy

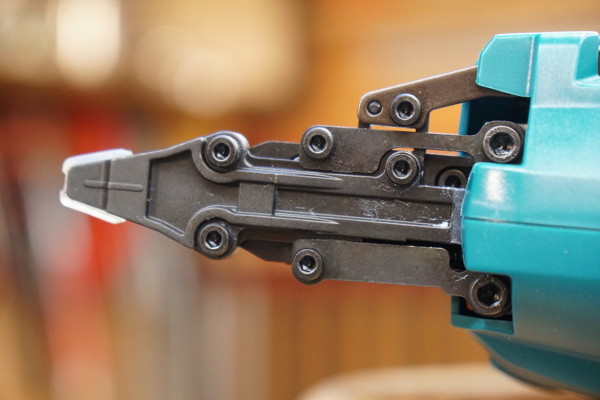

The Makita nose is longer and narrower, similar to a pinner style nose. This nose depresses slightly which results in the tool moving or shifting less.

This Makita brad nailer is accurate, and there are 2 visual indicators, on face and side of the tools nose, indicating where the brad nail is coming out from. The only trade off for the Makita nose, is that if it jambs, it is NOT a tool-less jamb change. The Makita requires the use of an on-board Allen wrench to remove the nose piece.

The Milwaukee contact tip has a minimal movement, approximately 3/32″ of depression and very little slop. The brad nailers with the least amount of “SLOP” in their contact bracket mechanism were the most accurate.

The DEWALT contact bracket has a decent amount of side to side play, and its tip is wider, which helped with angled nailing. However, this larger tip hindered accuracy. The DEWALT shoots high, and it’s not easily apparent to user where the nail will come out; up/down, or left/right.

DEWALT users will, no doubt, adjust their positioning, and “game it,” to get the accuracy they need. 9 out of 10 times, you don’t really need to be that accurate, unless you’re fastening outside miters or face nailing thin nailing location.

Metabo HPTs “Ass-End” is big, and the front right section is chunky. This hindered its line of sight, but the nailer has arrows indicating where the brad nail is coming from, and we were easily able to achieve accuracy.

The Milwaukee, with their Gen-2, moved the depth adjustment from the left side of the tool to the right side,” and recessed it a bit. This immediately improved the nailers line of sight for the vast majority of right-handed users. Recessing the depth adjustment knob further improved the line of side on the right side. The improvements to the Gen-2 nailer have made it more accurate, compact, lighter, and enjoys a much improved line of sight.

Contact Bracket – Tip

The Metabo HPT contact tip will not fire if you press down, and back off the surface a bit, to readjust the nailer. To fire a brad nail you need to fully back off the contact tip to reset the safety and then depress to engage the brad nailer. This can be a pain when trying to dial in your brad placement, and you find yourself moving the nailer around, to get into that “sweet-spot” nailing position.

One interesting thing about the DEWALT brad nailer is that when in contact [bump] mode, you can depress the contact safety and keep it depressed down and rapid fire trigger, as you slide the tool along the work surface. Or you have the option in bump-fire mode to hold trigger and punch the tool rapidly.

Fastener Length

Both the DEWALT and Milwaukee can accommodate brads from 5/8” to 2-1/8″. Makita and Metabo HPT can only accommodate fasteners up to 2” long.

Firing Modes

All of the nailers have the option to fire contact [bump fire] or sequential firing mode. Sequential fire more requires the operator to release the trigger and re-engage the tool to fire a nail and is a more accurate way to deploy a brad nailer.

All of the nailers fire brad nails reasonably fast, but the Milwaukee and DEWALT seemed to be the fastest, and were the most consistent in setting nails at the same depth, in all the woods tested.

Dry Fire Protection

All of the brad nailers, except Metabo HPT, have dry fire protection. Many of the tools have visual, yellow spring-loaded, indicator button in the magazine telling you that you are out of nails.

The Makita fires every single brad before locking the tool from firing, the DEWALT will fire all but 11 brad nails and the Milwaukee will fire all but 4 brads before locking out. Makita got it right on this one, because many times inserting a full strip of brads dislodges the small “left-over” nails, and causes reloading frustration or alignment.

LED Lighting

LED lighting was all over the place on these tools. The Metabo HPT and the Makita have super bright spot lights. The Metabo HPT light shines on the right side of the tool, but completely misses the contact point. The Makita shines on the left side and also completely misses the contact point.

The DEWALT uses two LEDs on either side of the tool and white washes the entire area, it’s more general lighting, not as bright, and not really task lighting.

The Milwaukee uses a cone shaped light pattern which is very bright, but it illuminates the tool tip from behind and produces a shadow.

The team favored the DEWALT lighting, followed by the Milwaukee lighting.

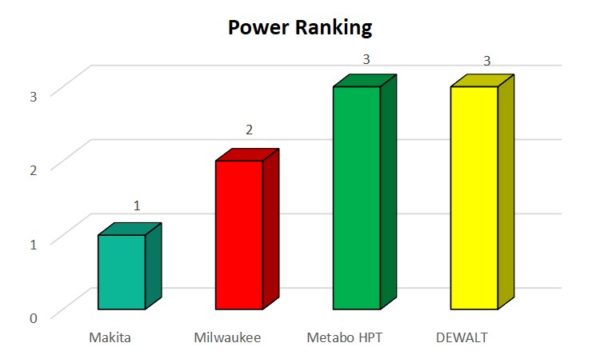

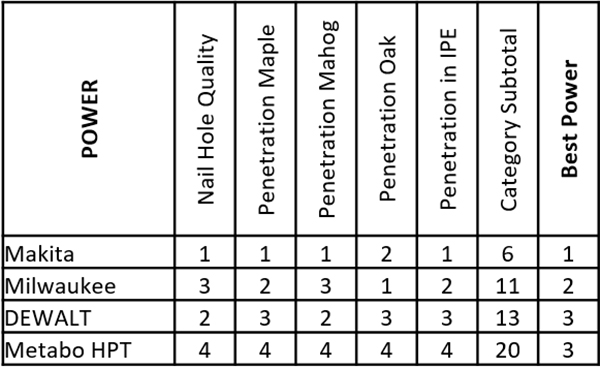

Power – WINNER – Makita

It seems cordless tools are an easier transition for the younger crowd, while older tradesmen seem to be more skeptical. The first question that comes up when asking carpenters what they think about using cordless finish nailers seems to be power.

This is certainly a fair question considering how effective pneumatic nailers have been in our industry. To evaluate power, several challenging wood species, to represented typical higher end trim applications that that many finish carpenters are facing today.

The following Species were used:

- Oak trim (3/4″ thick)

- Mahogany trim (3/4″ thick)

- IPE trim (3/4″ thick)

- Maple trim (3/4″ thick)

The Makita finished first for this category with a winning 6 points, while DEWALT and Milwaukee came in second and third place with 11 and 13 points, respectively.

The Milwaukee and DEWALT performed extremely well in this test by repeatedly installing brads at a consistent depth. Additionally, the Milwaukee was able to install and sink fasteners at its highest fastener depth-setting, while the DEWALT had to be adjusted more toward the middle of its depth of drive range to achieve the same result.

The Makita has a slight ramp up time but produced the nicest looking nail holes. All of the nailers were able to sink nails in all of these hardwoods quickly. The Metabo HPT is the slowest nailer, and that’s due to the fact that you need to release the contact tip almost all the way out, [travels too far] in order to fire the nailer.

“Milwaukee just feels like a “PRO” gun” ~ Stan Durlacher, TBBCrew

Nail Hole Quality

To evaluate how the nailers made holes, we examined a board full of hundreds of installed fasteners. A representative group of holes for each nailer was picked. In this particular evaluation, samples from the board were picked, in which fasteners were carefully placed, for maximum accuracy.

In this way, TBB chose samples that were not compromised by a rapid fire nailing process or from prematurely raising the nailer. A USB 400 power microscope was used to examine the holes, ensuring a fairly representative pattern of each individual nailer.

As you can see in the captioned examples below, the pencil mark, used for accuracy, is visible in each photograph. Each of these nailers produced very consistent and high quality fastener holes. But under close examination, slight differentiation allowed for relative quality ranking.

The first photograph is the hole from the Makita nailer. This hole is extremely well-formed and has very little tear-out on the surrounding wood. This type of hole was rated as the highest quality of the nailer samples.

Makita Nail Hole Pattern

Milwaukee produced a hole that came in a close second in quality to the Makita. The Milwaukee samples had a hole that was closer in size to the head of the fastener but exhibited more tear-out at the periphery of the holes. The smaller size was the deciding factor in placing this nailer in second place over the DEWALT .

Milwaukee Nail Hole Pattern

DEWALT also produced high quality holes. This nailer had more consistent tear out on one side of the driver blade. The other three sides of the hole were well formed. That the driver blade was larger than the fastener heads, and created a larger hole than Makita and Milwaukee.

DEWALT Nail Hole Pattern

All three of these cordless nailers produced high quality holes that would be easy to patch in finish work. Using the microscope camera showed a clear and consistent difference between the three top nailers.

Metabo Nail Hole Pattern

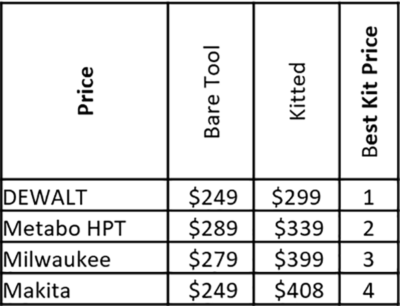

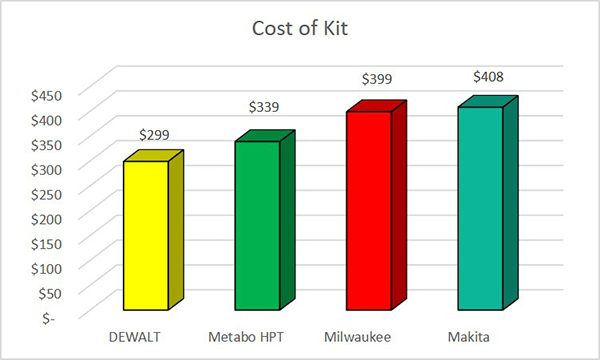

Best 18 Gauge Cordless Brad Nailer – Kit Price WINNER – Metabo HPT

Pricing is a key part of the purchasing mix, and it’s crucial that you get it right in order to determine the Best Cordless Brad Nailer. There are certain considerations to make when buying power tools to get the most out of them and be able to complete your work application.

For this Head-to-Head kit price [at the time of publication] was evaluated and scored for your review. Note – Makita does not offer a kit, so we created a kit by combining the bare tool, a battery and charger, which raised its comparison price.

Buy Now From Our Sponsored Retailers

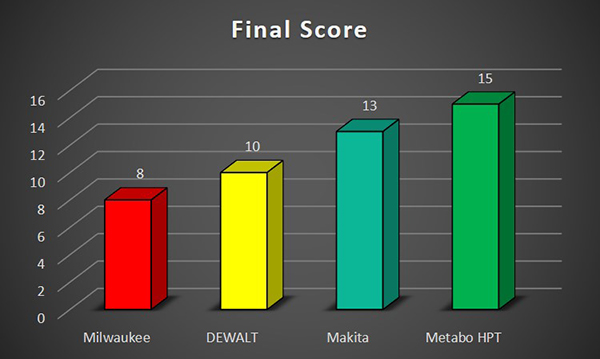

BEST Overall 18 Gauge Cordless Brad Nailer – WINNER – Milwaukee

Even Though this category is always tough to decide, two brad nailers stood out and rose to the surface quickly during deliberations. The winner is decided by the entire testing group based on all the testing and individual evaluations.

BEST Overall 18 Gauge Brad Nailer –Milwaukee

The Milwaukee M18 FUEL 18 Gauge Brad Nailer installed nails consistently at the desired set depth, every time. There is no “ramp up time” for this nailer, meaning that the tool does not pause to recharge itself, The Milwaukee M18 placed a nail as fast as we were able to accurately aim, set and pull the trigger.

The tool’s recoil is minimal, and the word “smooth” was used to describe it. Nailing results were consistent and repeatable in all out tests. Milwaukee took their time re-designing this nailer and it shows. This brad nailer consistently installed brad nails fast, at the proper depth, in hard and soft woods while leaving clean nail holes matching the head of the nail.

Coming in second place for the Best 18 Gauge Cordless Nailer is the DEWALT 20v 18-Gauge Brad Nailer. It’s been on the market for almost two years and is still a top contender, Milwaukee beat it by improving small areas of this already proven nailer.

The DEWALT mechanical switches, and straight forward design make it an easy to use tool. This brad nailer also consistently installed brad nails fast, at the proper depth, in hard and soft woods, and left clean nail holes.

Final Thoughts

Having a battery operated brad nailer, on the battery platform that you use, makes sense. Not having to worry about setting up a compressor, hose or gas cartridge expiration dates, fuel levels or cartridge cost is a plus.

The most impressive feature of these brad nailers is their rate of fastening that is achieved with zero ramp-up time. You can install fasteners accurately at a decent rate of work with no disruption to work speed.

Battery powered brad nailers allow you to “cut the air hose,” and give you the freedom from gas cartridges.

Now the job-site advantage belongs to the battery powered nailers, especially when you factor in that so many brands offer so many tools on their battery platform.

We get lots of comments about how we make the final rankings. As we’ve stated, there are hundreds of ways to compare tools. The good news is we’ve openly shared ALL the data from our tests, and you can rank the tools however you want. Don’t care about an item we ranked? No problem. Simply remove that from the matrix above and re-rank them. Hopefully you’ll find this Head-To-Head useful when comparing 18 gauge cordless brad nailers.

If you have a moment, please check out our other Head-to-Head Tests.

Best 18 Gauge Cordless Brad Nailer Video Review

About the author

9 Comments

Leave a comment

Disclosure

Product reviews on this site contain our opinion of a product or service. We will always strive for objectivity and transparency in our reviews. Our goal is to provide readers with honest, objective information based on our own experiences. We never have and never will accept payment in exchange for a positive review. Many of the products that we review are provided to us for free by a manufacturer or retailer. In some cases, we also have advertising or affiliate relationships with manufacturers and retailers of products and services we review. For additional information please visit our additional disclosure policies.

Great video and great article. However Ridgid and Ryobi where part of the testing. In the video about finish nailers and Ryobi had a respectable third place. I understand that more nailers mean more time but for consistency from an article to another it would have been appropriate to at least mention why ridgid and ryobi where not part of the testing (example because ryobi is brushed) excuse my english i’m french canadian

Thank you . Great evaluation ; very thorough . You hit a home run, covering all the bases. You get an “A” for presentation and perinate information from an old , cranky, retired teacher .

Your evaluation , definitely guided and determined my purchase.

Thanks again,

Rick Ripple “Rip”

Fabulous review! Very scientific. Love the iso/3d graph too!

I also would liked to have seen Ridgid evaluated. What goes into the selection process of which tools are evaluated? On the product page for Ridgid it has a 5 minute video on maintenance. That seems like a feature to me in addition to it’s lifetime warranty but I suppose it may suggest that the tool breaks down that much. I don’t see ease of maintenance addressed here. Are these brands ‘maintenance free’?

Shane – We reach out to every manufacturer in a category months in advance of one of these tests. We invite them to submit a tool for the evaluation. From time to time they “pass”, sometimes a lack of stock, sometimes they don’t feel it compares well with others in the category. We rely on samples to do these tests as we don’t get paid to do this. There is VERY little maintenance for most of these, keep them clean basically.

I am in the market for a cordless brad nailer and I found this review very helpful and timely. Thanks for the good review.

what is milwaukee electric brad nailer as you soon model number

Although I enjoy these comparisons, the real issue is batteries. Once someone selects a brand, whatever it is, and buys a few tools and batteries for it, that person is unlikely to switch to another brand because of the cost of batteries. I believe that all the brands sell the batteries separately, and they are EXPENSIVE. I might switch brands of glue after a comparison, because glue is low cost and gets used up. However, I have used Dewalt for years, and I have many Dewalt tools and probably ten batteries. I’m not buying new batteries and chargers because some other brand has a better nailer, drill, heat gun, etc. If someone comes up with a universal battery, they will be rich.

You are not wrong. However, there are times when contractors will switch things up, whether that’s re-tooling, or buying a specialty tool. It’s not uncommon to see a couple brands in a job trailer, just depends on how people are running their business. Some guys will slowly move to another brand if they like the direction that company is moving in. But you’re correct…many just never leave a brand.